Best practices for applying commercial IGU glazing

by arslan_ahmed | March 8, 2024 7:47 pm

[1]

[1]By Amy Becker

Building occupants and residents can enjoy the daylighting, great views, and comfort provided by commercial fenestration. Given continual advances in glazing technology, specifiers need expert resources to select the most optimal glazing systems for their projects. The Fenestration and Glazing Industry Alliance (FGIA) has updated the IGMA TM-3000, North American Glazing Guidelines for Sealed Insulated Glass Units for Commercial and Residential Use, which can be used for this purpose.

Armed with a detailed understanding of the different components, how they are manufactured and integrated into glazing systems, testing standards, and more, specifiers can make informed decisions when it comes to selecting insulated glazing units (IGUs).

IGU performance standards

Before delving into some relevant technical details in the updated standard, it is worth pointing out the long-term thermal performance of a complete fenestration system depends upon the overall performance and durability of its IGU. To best ensure performance, 101/I.S.2/A440-22, North American Fenestration Standard/Specification for windows, doors, and skylights (NAFS) requires fenestration IGUs to meet ASTM E2190 requirements and be certified by the National Fenestration Rating Council (NFRC) for thermal performance. This is also a requirement of the U.S. Environmental Protection Agency’s (EPA’s) ENERGY STAR program.

For NFRC certification, FGIA offers the following three programs:

- Associated Laboratories, Inc. (ALI) AAMA Sealed Insulating Glass Certification Program

- IGMA of Canada (IGMAC) Certification Program

- Insulating Glass Certification Council (IGCC)/IGMA Insulating Glass Certification Program

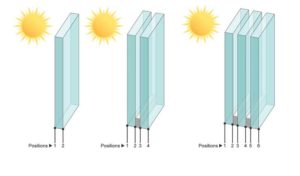

[2]Returning to IGMA TM-3000, the updated standard covers considerations for glass types, framing, clearances, setting blocks, spacer shims, glazing materials, glazing systems, storage and handling, glass protection, and cleaning for both double- and triple-glazed IGUs.

[2]Returning to IGMA TM-3000, the updated standard covers considerations for glass types, framing, clearances, setting blocks, spacer shims, glazing materials, glazing systems, storage and handling, glass protection, and cleaning for both double- and triple-glazed IGUs.

The document is all inclusive, addressing every aspect of glazing systems from soup to nuts. The comprehensive guide walks manufacturers, fabricators, specifiers, and contractors through all the glazing system components, addressing important points to consider, and things for which to look out.

Most helpful for specifiers are the sections on glazing materials and glazing systems where a detailed understanding is provided on all aspects and types of systems.

Glazing materials

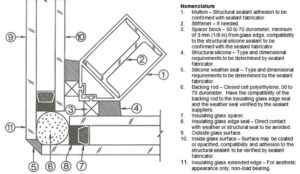

The glazing materials section in IGMA TM-3000 largely focuses on sealants. For glazing systems, this typically includes silicones, polysulfides, polyurethanes, acrylics, latex, and butyls applied as gunned-in-place glazing sealants. Applications include sash joinery sealants, such as seam sealers, back bedding sealants, exterior weather sealants, heel and toe beads, butt-joint sealants, interior air seals, and structural glazing sealants.

[3]

[3]When evaluating these systems, it is critical to check that the selected materials for the glazing system and interior of the IGU are compatible with all glazing system components. This includes the IGU sealant/sealants, which may be in contact with or encased under expected environmental conditions. For example, sealants which contain linseed oil, mineral oil, vegetable oils, certain excess plasticizers, and/or substances which release significant amounts of solvents or acids when curing, may cause IGU seal failure and/or surface contamination on the exterior or interior of the unit.

Silicone glazing sealants generally release a small amount of invisible silicone material over time. This material then migrates up to 100 mm (4 in.) or more across the #1 outer surface of the glass. This very thin layer of silicone normally only is seen by a difference in wetting action during periods of rain. That said, this film cannot be removed and will attract dirt. Consequently, dry-glazed gaskets are generally preferred for use with #1 surface coated glass.

Sealants used as heel beads or air and weather seals in contact with the IGU should have the ability to remain pliable under all expected temperatures, temperature, UV exposure, and environmental conditions as to not interfere with the movement capability of the unit, which could lead to possible glass breakage or seal failure.

Be aware that IGUs with heat-absorbing or reflective glass can reach temperatures of 60 C (140 F) or more in sunlight and still air. IGUs used in spandrel areas and vacuum insulated glazing (VIG) may become even hotter, as high as 90 C (194 F) or more. Consequently, glazing materials must be able to perform at these temperatures. With VIGs, since there is no air flow or cooling effect in the vacuum cavity, glass temperatures may exceed limits for thermal breakage. Therefore, specifiers should verify with the fabricator regarding the feasibility of the installation.

[4]

[4]For sealants, in addition to tapes, gaskets, or fins, they must provide a weathertight seal to the glazing cavity for the life of the installation. Care should be given to these glazing materials which can experience shrinkage over time. Consequently, special installation or corner sealing treatments should be considered.

The glazing sealant manufacturer should be consulted to verify the sealant’s life expectancy and performance is adequate installation. Information on correct application techniques or guidelines for compatibility, if required, should be requested.

In addition, the glazing sealant manufacturer should be consulted to review the sealant performance in terms of adhesion, movement capability, compatibility with IGU sealants, and adequate life expectancy for its intended use. It also is crucial that compatibility testing is performed for the IGU’s edge and primary sealant system with glazing sealants, setting blocks, gaskets, or other components in direct contact or close proximity. This testing will help prevent IGU seal failure and glass surface contamination.

[5]

[5]Glazing systems

The guidelines refer to three common types of IGU glazing systems: structural glazing, butt glazing, and dry glazing.

Structural glazing or stopless glazing, where the IGU is retained only by a silicone sealant or adhesive joint, requires special care as seal failure of a unit glazed without exterior stops could lead to the exterior lite falling from the building. The following factors should be considered in the design and installation of IGUs for stopless glazing.

- The adhesion characteristics of the silicone sealants should be tested with the corresponding spacers, corners, frame members, and glass with any applied coatings for each batch of the component materials.

- The compatibility of all components in contact with each other—including glazing sealants, IGU assembly sealants, setting blocks, gaskets, and joint backers—should be verified with component suppliers.

- Sealant selection should withstand long-term weathering effects including solar UV radiation, temperature extremes, and water exposure.

- Approximately 50 percent of the negative wind load on a unit is normally carried by the IGU sealants. If the IGU seal were to fail or an inner lite breakage were to occur, an increase of the negative load could be imposed on the IGU sealants.

- The IGU assembly sealant and structural silicone sealant should accommodate all movements of the structural frame and glass caused by wind, live and dead load deflection, and thermal expansion.

- Seals at the edges of the exterior glass components are weather seals and their width and elasticity need to ensure that excessive stresses are not transferred to the IGU. Setting blocks may have to be modified to suit the framing system but still be suitable for their intended function.

- Heat-strengthened glass should be used for the offset IGU at a corner condition.

[6]

[6]Butt glazing or stopless glazing without a supporting mullion on any IGU edge is not recommended unless the glass is stiff enough to avoid the high shear stresses caused by wind loads on the unit sealant, potentially leading to seal failure. To determine whether this is relevant, consult the IGU fabricator.

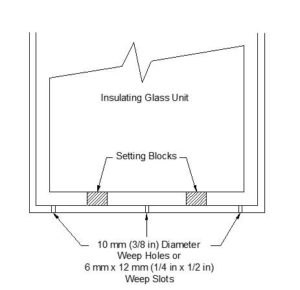

Dry glazing is the common designation for the portion of the glazing system that uses a non-mastic compound as the seal between the glass and frame. Common dry glazing systems may use foam tapes or extruded rubber gaskets as the sealing material. The amount of compression and the type of sealing material determines reliability against possible water infiltration into the glazing cavity.

This is necessary as water ponding directly impacts the longevity of IGU seals. Consequently, weep systems should be employed to prevent water ponding in the glazing cavity. Compatibility of the dry glazing materials with IGU sealants should be confirmed through testing by the sealant manufacturer.

Gasket guidance

[7]

[7]Dry glazing includes the following types: compression seals, structural gaskets (zipper or lock-strip gaskets), vinyl or marine wrap glazing, and foam tapes.

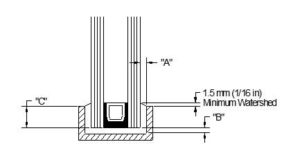

Compression seal gasket glazing systems use dense and/or sponge gaskets to achieve a compression seal. All major glazing components and materials—glass, gaskets, aluminum, wood, fiberglass, and vinyl—have tolerances. However, tolerances can accumulate and cause major problems such as glass not fitting and gaskets not sealing. To verify individual tolerances, check with the fabricators.

Another item for consideration, which may affect sealing ability, is the possibility of bowing, warping, and twisting of sash members. Molded and/or vulcanized corners are available in extruded gaskets. Molded corners reduce the possibility of water penetration at the corners, which is normally the weakest point in the system. If molded corners are not used, caulking may be required in the corners. Weep systems are essential with any compression glazing system.

[8]

[8]Gaskets should be sized longer than the length needed. If the gaskets are stretched during installation, they may return to their original length causing gaps at the corners.

Sponge or dense gasket systems may require special installation procedures to attain proper compression forces evenly distributed around the glass edge. The manufacturer should be consulted for proper procedures.

Structural gaskets

Structural gaskets, also called zipper gaskets or lock-strip gaskets, are pre-formed, cured elastomeric mechanical seals used to install glass or solid panels in a supporting framework. Made in two pieces, a main body that holds the glass or infill material in place and a wedge-like continuous locking strip is inserted into a recess in the main body, thus bringing pressure to bear upon the surface of the glass.

Some structural gasket systems use straight lengths of extruded gasket material, which can be cut to length and assembled in the field using an adhesive to join the corners. Most structural gasket systems, however, are pre-formed in the factory as continuous closed frames that are then joined in the field with an adhesive.

[9]

[9]The gasket should be made at least one percent larger than the opening into which it is to be installed so it is under slight linear compression. The frame holding the gasket should be clean, smooth, and free of imperfections. Corner offsets of the frame should not exceed 1 mm (0.03 in.) and all frame joinery must be sealed.

Precise glass size and opening size are of critical importance when setting in framing members. Likewise, lip pressure and bite are extremely important in achieving weather-tightness. Consequently, close attention should be given to the framing, gasket, and glass tolerances.

Boot glazing

Boot glazing, also called wrap-around marine glazing material, is available in rolls or strips which wrap around the perimeter length of the IGU. As a common practice, the boot is clipped at the corner to fit. Framing members are pressed into position over the boot and then joined and fastened at the corners.

Since the boot wraps around the edge of the IGU, it often comes in direct contact with the IGU edge sealant. Therefore, compatibility should be checked. This often is verified through IGU fabricator or sealant manufacturer testing.

[10]

[10]The boot is extruded as a continuous strip. Weep holes, a minimum of 10 mm (0.39 in.) in diameter, are essential and should be punched through the section that covers the bottom edge area of the IGU. They should be spaced at 100 to 150 mm (4 to 6 in.) on center around the perimeter of the IGU. Both the frame and boot systems’ weeping should be designed to adequately drain moisture from the system. Clipping the corners does not provide an adequate positive weep system. Setting blocks may have to be modified to suit the framing system while remaining suitable for their intended function.

Foam tapes are extruded closed-cell foam material of various densities and dimensions, normally packaged in rolls. A pressure-sensitive adhesive is applied to one or both sides of the foam tape. Proper compression of the foam tape and sealing of the cut and butt joint corners is necessary to achieve airtight and watertight seals. For more detailed information regarding correct usage of foam tapes, contact the foam tape manufacturers.

Glass type and thickness should be installation-specific, firmly supported and resist applicable loads based upon ASTM E1300, Standard Practice for Determining Load Resistance of Glass in Buildings, or ASCE/SEI 7, Minimum Design Loads and Associated Criteria for Buildings and Other Structures, as determined by code jurisdiction. Glass type and thickness can be determined using IGMA’s Glass Design computer program.

[11]

[11]Pre-glazing considerations

When selecting glazing products, specifiers can feel more confident about their specifications if manufacturers have taken certain pre-glazing considerations into account. This includes manufacturers’ shop drawing review, a pre-installation procedures meeting and inspection of the glazing system, and breather or capillary tubes.

For the shop drawing review, project-specific glazing shop drawings or fenestration system details can be submitted to the IGU sealant manufacturer for review. The glass fabricator should also be consulted regarding the glass construction, strength, and compliance with specifications and glazing details. In addition, the sealant manufacturer should be consulted for assurances of sealant compatibility and strength, approval of spacer shim materials, and for recommendations on optimum joint configuration and proper adhesion to glass and support members.

Before glazing, application guidelines from the IGU fabricator, sealant, or other glazing material suppliers should be reviewed with the on-site glaziers or shop personnel setting the glass in fenestration systems.

[12]

[12]As glazing begins, fabrication tolerances should be checked. For example, the glazing should be free of debris and obstructions, weep holes should be open and free of obstructions, and glazing surfaces should be free of moisture, dirt, grease, oil, and other contaminating materials.

Care should be taken that screws, bolts, rivets, and weld fillets do not protrude into the glazing channel which would reduce the minimum required face or edge clearances.

Further, all joinery, connectors, screws or bolt heads, rivets, and water dams should be effectively sealed; all steel or wood glazing rabbets and contact areas of dissimilar materials should be effectively primed; and setting blocks, weep baffles, and edge blocks should be properly located in the glazing channels.

In inspecting the glass, the IGU should be measured for proper dimensions, recognizing fabricator-published tolerances. Also, glass edges, sealant uniformity, and coating quality should be inspected according to the glass manufacturer’s guidelines.

For VIG, consider inspection of pillars, or objects that keep lites from touching, and the pump-out port, or area where the air is pulled to create the vacuum, to make sure they meet the fabricator’s specifications. The fabricator should also set questionable glass aside for inspection. For breather or capillary tubes, consult the IGU fabricator for proper installation procedures.

Glass protection and cleaning

Since it is difficult to protect glass from damage during construction, it is important to check and daily document glazing materials if building teams need to provide evidence of post-glazing damage. In addition, a number of best practices should be followed to best protect the glazing on the jobsite.

- Paint, plaster, and sealant spills or splashes should be removed from the glass immediately.

- Protection should be provided to prevent weld splatter, sand blasting, concrete alkaline deposits, or other caustic materials from contacting glass surfaces as these materials will permanently damage glass surfaces.

- Protective coatings or release agents applied to the glass should be evaluated for compatibility to the IGU, the glazing system, and the fenestration system’s frame.

- Glass surfaces should be cleaned soon after installation and on a regular basis if surrounding construction leaves deposits such as concrete runoff, rust stains, sealant bleeding, etc., on the glass.

[13]

[13]Knowing IGU glazing guidelines

IGUs can be a performance asset to a commercial project. Specifiers can refer to guidelines such as those found in IGMA TM-3000 to ensure they are making informed decisions when it comes to selecting IGUs.

Notes

1 See the Fenestration and Glazing Industry Alliance (FGIA) standard, IGMA TM-3000, North American Glazing Guidelines for Sealed Insulated Glass Units for Commercial and Residential Use.

2 Refer to AAMA/WDMA/CSA 101/I.S.2/A440-22, North American Fenestration Standard/Specification for windows, doors, and skylights (NAFS), store.fgiaonline.org/pubstore/ProductResults.asp?cat=0&src=A440-22.[14]

3 Refer to ASTM E2190, Standard Specification for Insulating Glass Unit Performance and Evaluation, www.astm.org/e2190-19.html.

4 Refer to ASTM E1300, Standard Practice for Determining Load Resistance of Glass in Buildings, www.astm.org/e1300-16.html[15].

5 See American Society of Civil Engineers/Structural Engineering Institute, ASCE/SEI 7, Minimum Design Loads and Associated Criteria for Buildings and Other Structures, ascelibrary.org/doi/book/10.1061/asce7[16].

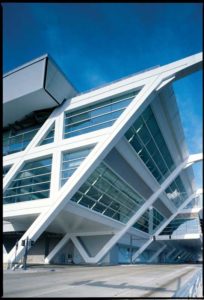

6 Visit LMN Architects, the Seattle Convention Center Summit Building, lmnarchitects.com/project/washington-state-convention-center-addition[17].

7 Learn more about the Viracon, Architectural Glass Gallery: taxation building, www.viracon.com/projects/view/id/1468/[18].

8 For more information, visit Vitro Architectural Glass, Acrisure Stadium, projects.vitroglazings.com/acrisure-stadium-formerly-heinz-field[19].

9 For more information, visit Vitro Architectural Glass, David L. Lawrence Convention Center, projects.vitroglazings.com/david-l-lawrence-convention-center[20].

10 Visit EFCO, 1717 Innovation Center, www.efcocorp.com/galleries/detail/662[21].

11 See 365 Nicollet, www.365nicollet.com[22]

Author

Author

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/03/dreamstime_l_286908170.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/glossary.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/1GlassPartIII-Slide14-IGUwithSpacer_FGIA.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/2GlassPartII-Slide10-SurfaceOrientation_FGIA.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/8NJ-TaxationBuilding_GregWestPhotography_Viracon-Apogee.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/7WA-SeattleConvCtr_iStock_Technoform.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/3IGMA-TM-3000_Figure8-1-StructuralGlazing-OffsetCornerDetail_FGIA.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/5GlassPartIII-Slide15-Spacer.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/4IGMA-TM-3000_Figure3-1-WeepHolesPositioning_FGIA.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/9PA-AcrisureStadium_Vitro.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/6IGMA-TM-3000_Figure4-1-EdgeAndGlassClearancesDiagram_FGIA.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/12MN-365Nicollet_©FarmKidStudios-EFCO.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2024/03/10PA-LawrenceConventionCenter_Vitro.jpg

- store.fgiaonline.org/pubstore/ProductResults.asp?cat=0&src=A440-22.: https://store.fgiaonline.org/pubstore/ProductResults.asp?cat=0&src=A440-22.

- www.astm.org/e1300-16.html: https://www.astm.org/e1300-16.html

- ascelibrary.org/doi/book/10.1061/asce7: https://www.constructioncanada.net/airtightness-and-moisture-management-luncheon/

- lmnarchitects.com/project/washington-state-convention-center-addition: https://lmnarchitects.com/project/washington-state-convention-center-addition

- www.viracon.com/projects/view/id/1468/: https://www.viracon.com/projects/view/id/1468/

- projects.vitroglazings.com/acrisure-stadium-formerly-heinz-field: https://projects.vitroglazings.com/acrisure-stadium-formerly-heinz-field

- projects.vitroglazings.com/david-l-lawrence-convention-center: https://projects.vitroglazings.com/david-l-lawrence-convention-center

- www.efcocorp.com/galleries/detail/662: https://www.efcocorp.com/galleries/detail/662

- www.365nicollet.com: https://www.365nicollet.com/

- abecker@FGIAonline.org: mailto:abecker@FGIAonline.org

Source URL: https://www.constructionspecifier.com/best-practices-for-applying-commercial-igu-glazing/