Transforming construction with ultra-high-performance concrete

by maz_atta | July 30, 2021 12:00 pm

Monica Schultes

[1]

[1]While concrete has been around in some form for thousands of years, the newest iteration, ultra-high-performance concrete (UHPC), is creating a stir. UHPC has been used to build bridges and architectural façades around the world. However, in the United States, UHPC’s use has been limited to-date—its widest use is in joints and connections.

Ongoing research and development efforts are changing that. This technology can have a big impact and be adopted in both building and transportation construction. The U.S. precast concrete industry is well-suited to capitalize on the unique performance characteristics of UHPC and has made substantial strides.

UHPC is emerging as a material with the potential to revolutionize segments of the precast concrete industry. With creative designs and new guidelines, UHPC can be cost-competitive on a first-cost basis and provide significant value on a long-term life-cycle cost basis. By taking advantage of its key properties, precast and prestressed UHPC components can transform the industry, with their more efficient use of materials and enhanced long-term performance.

Defining UHPC

UHPC was introduced as ‘reactive powder concrete’ in the early 1990s. It contains many of the same materials as conventional concrete such as cement, supplementary cementitious materials (especially silica fume), sand, and chemical admixtures. However, the materials and proportions are optimized within the mixture to form a dense particle packing matrix. UHPC also differs from conventional concrete by including steel fibers.

The quantity of cementitious materials in UHPC is typically more than double of conventional concrete. Instead of referring to water-cement (w/c) ratios, these special blends refer to water-binder ratios (w/b), which are often less than 0.2. The dense particle packing, combined with the extremely low w/b, creates a highly refined microstructure providing exceptional strength and durability.

There is no standard definition of UHPC, but it typically has compressive strengths of more than 119,969 kPa (17,400 psi), with some able to achieve strengths up to 206,843 kPa (30,000 psi). However, compressive strength is not the most significant enhancement. The key difference between UHPC and other concrete is its high tensile strength and durability, due to the combination of the sophisticated microstructure and the use of steel fibers.

UHPC’s potential

The precast concrete industry has potential to improve its product offering by using UHPC, as it will enable the production of precast concrete components that are thinner and lighter, yet capable of longer spans with less reinforcing. UHPC is more than just new mixture proportions.

“If we dwell only on the material side then we will keep filling joints with UHPC,” said Maher Tadros, founder of eConstruct USA LLC, a Nebraska-based structural engineering firm. “The real benefit comes from our engineers and designers who are creating new products. That is where we start the revolution.”

Two conditions must be met for UHPC to see widespread implementation. First, precast concrete plants must be able to produce it reliably and cost-effectively. Second, design of new components and systems capitalizing on its unique performance characteristics must be developed.

Research team

[2]

[2]The Precast/Prestressed Concrete Institute (PCI) is funding an applied research project led by eConstruct USA LLC in joint venture with Wiss, Janney, Elstner (WJE) Associates Inc., the University of Nebraska–Lincoln, the Constructed Facilities Laboratory at North Carolina State University, and Louisiana Tech University.

PCI’s primary goals are to create cost-effective UHPC using local materials and develop design guidelines for optimized long-span structural members for buildings and bridges.

“While UHPC has been used successfully all over the world, the main drawback in the United States is the cost and the lack of nonproprietary mix designs,” said Greg Force, PCI Research and Development Council chair. Another missing component, he said, “is the means for acceptance by the general design and construction community.”

The research team is not testing theoretical models, but rather the rapid implementation of UHPC in actual structural members for real projects. To emphasize the point, Tadros refers to bridges built in Iowa more than 10 years ago that were not repeated because the premium cost was funded by the federal government.

“We cannot afford to sit around and wait for one project in a while to come along,” said Tadros.

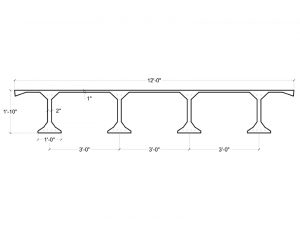

The research addresses precast and prestressed concrete members that can span up to 18 m (60 ft) for buildings and 76 m (250 ft) for bridges. The building beams are voided inverted tee beams and the joists are thin-walled voided slabs with stem openings (block-outs) to allow utility placement. All products are pretensioned in the longitudinal direction.

Phase one in three parts

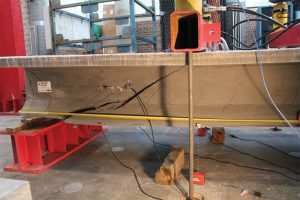

Lee Lawrence, WJE principal, describes three distinct parts of phase 1 of the research project. The first was the conceptual design side or creating different prototypes of structural members to work with this new type of concrete and its unique attributes. The second was the materials aspect, or helping the contributing producers develop UHPC with local materials. The third part involved the structural evaluation of small-scale specimens that were developed.

This extremely dense material with enhanced mechanical properties lends itself to slender and more durable structures. Concrete is known to be weak in tension and this enhanced version also takes advantage of pre-stressing. Steel fibers are often added to resist the applied shear forces without help from steel reinforcing bars. This eliminates time spent ensuring bars are designed and detailed properly and placed within clear cover requirements.

“The precast concrete is not only thinner and lighter, but we can realize labor savings by removing secondary reinforcing steel,” said Force. That may prove to be a critical factor, given the uncertain future of the labor force in some areas of the country.

With fewer internal reinforcement needed, UHPC cross sections have less volume, therefore, less weight, while providing the same capacity as conventionally reinforced concrete. Multiple pieces stacked on a truck would reduce transportation costs.

Plant perspective

“The challenges inherent in the complex mixing procedures are the same qualities making it well-suited for use in a precast concrete setting,” said John Lawler, WJE principal. “The precast concrete producer has more control over their production processes, and the time required to handle and place the concrete is limited in that setting.”

However, precast concrete production facilities need to determine their ability to handle the different types of materials in appropriate quantities.

“You cannot just dump a bag of fibers into the mixer and call it UHPC,” said Lawler.

Phase 1 developed information to support implementing UHPC at the precast concrete plant, which is intended as a how-to guide for precast concrete producers. It outlines ways to develop UHPC mixture proportions, how to use and select locally available materials, and ways to use existing equipment or consider investing in new equipment.

“The guide was written with the idea of smoothing the transition from conventional concrete manufacturer to one using UHPC,” said Lawler.

For production adopting UHPC is similar to what happened more than 20 years ago with self-consolidating concrete (SCC). SCC was a means to improve production processes and reduce labor. Some producers embraced the technology, mobilized quickly, trained personnel, and positioned themselves to make efficient use of SCC. With the new guidelines from this project, precast concrete producers can gear up quickly to produce UHPC.

“I feel like we have made significant headway; all six participating producers were able to reproduce a mix with local materials, no matter where they were located in the United States or Canada,” said Lawler.

New concepts

[3]

[3]“The mix design aspect is critical,” said Lawrence. “However, it was also important the team does not get bogged down with traditional components and what had been done in the past. Given the high tensile strength of UHPC, we wanted to take advantage of these unique mechanical properties.”

“Rather than falling prey to the old mindset of using stemmed members, we challenged the flat floor concept,” said Force. “There has been pushback regarding the weight and depth of double tees.”

Rather than consider a variation on that theme, one concept emulates a double-slab system.

“If these flat-deck products can incorporate other trades offsite to meet the needs of owners and constructors, that will be a game changer. That will bring added value as precast concrete producers embrace true modular construction and evolve into systems builders rather than just manufacturers,” said Force.

Long-span precast concrete components were designed, produced, and tested by the project team in conjunction with volunteer producers across the country. Despite the higher cost of the raw materials, the optimized designs and reduced cross sections will make these UHPC products competitive with steel and other similar materials, and eventually with conventional concrete products.

Optimized space

Traditionally, precast concrete cladding for a multistory building was 152 mm (6 in.) thick or more. Now 51 mm (2 in.) is achievable with UHPC. In terms of cladding, glass-fiber-reinforced concrete (GFRC) has long been less than 51 mm but UHPC may be able to carry loads GFRC cannot. Removing the weight from the building also impacts the foundation. A residential project with parking underneath can have 18 m of column-free space, which enhances the efficient use of the space. Double-tees could be another option, if needed.

“The clear spans in the garage and throughout the structure are revolutionary by themselves,” said Tadros.

A promising concept for floors allows for a 18 m length with a depth of 560 mm (22 in.). The relatively shallow structural depth incorporating the mechanical, electrical, and plumbing (MEP) systems provides a cost-effective story height. Tadros has not seen a product like this voided slab system spanning 18 m, with the top and bottom of the product only 25 mm (1 in.) thick.

The research team completed phase 1 and “early results are fantastic,” said Tadros. “The outcomes show this can be done without huge capital investment.”

Specifying UHPC

An important work product from the first stage was developing a draft guide specification that can be used if an owner wants to specify UHPC precast concrete. The language can be used for either a building or transportation project. In addition to the specification for UHPC materials qualification and acceptance, the team created design guidelines with detailed design examples.

The next steps involve testing large-scale members.

“These lab assessments are simply to validate our design recommendations and to refine them if required. We already know UHPC works; we are just trying to reinforce that it is cost-competitive,” said Tadros.

After that, technology transfer is vital to disseminate the information to the public. Like every industry, forward-thinking businesses will embrace the opportunity. The form and equipment supply companies are also vital to advance this effort.

“New forms for the shapes and cross sections created by structural engineers such as myself are needed to cast products for the same span and load that use only half of the concrete. This is not just adjusting mixes, it is high-level engineering,” Tadros said.

Changing mindsets

When PCI and its members champion UHPC in the United States, there will be a groundswell of excitement about the future.

“In the interim, I envision a building products producer will still utilize ‘regular’ concrete to cast the myriad components for a variety of projects,” said Force. “It might take two separate and distinct batching procedures and equipment. That is not insurmountable, given what we have learned to this point.”

“Civil engineers are conservative by nature and reluctant to take risks with new technologic advances because the consequences are significant. However, there are those who are ready to push the envelope, and in 10 years I hope to see significant market penetration,” said Lawler.

“There still needs to be market education and transformation. To change the mindset of the design community that the common 9- x 9-m (30- x 30-ft) grid is obsolete and adopt an 18- x 18-m (60- x 60-ft) layout is a huge paradigm shift,” said Force.

In addition to precast concrete producers who believe in UHPC, “we also need owners and developers willing to build with it and consulting engineers willing to design with it,” said Tadros. “All of these components have to pull together to achieve successful commercialization. That is our challenge going forward.”

Conclusion

As it will likely be used in transportation and building applications, UHPC’s impact on construction will be profound. Owners, project managers, architects, and engineers will benefit from its many advantages: higher strength, cost-competitiveness, thinner and lighter-weight components, and durability.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/08/Figure-3.-Specimen-after-failure.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/08/Ingredients.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/08/Figure-2.-Ribbed-slab-cross-section.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/08/Schultes_Headshotcrop.jpg

- mmschultes@gmail.com: mailto:mmschultes@gmail.com

Source URL: https://www.constructionspecifier.com/construction-ultra-high-performance-concrete/

[4]Monica Schultes, PE, has a degree in civil engineering and an MBA. She spent 13 years as executive director for what is now the Precast/Prestressed Concrete Institute (PCI) Mid-Atlantic region. Currently, Schultes is a contributing technical writer for PCI’s Ascent and Aspire publications as well as directing the Pennsylvania Precast Association. She can be reached via email at mmschultes@gmail.com[5].

[4]Monica Schultes, PE, has a degree in civil engineering and an MBA. She spent 13 years as executive director for what is now the Precast/Prestressed Concrete Institute (PCI) Mid-Atlantic region. Currently, Schultes is a contributing technical writer for PCI’s Ascent and Aspire publications as well as directing the Pennsylvania Precast Association. She can be reached via email at mmschultes@gmail.com[5].