Custom-balanced doors: Step into universal design

by tanya_martins | April 24, 2025 2:00 pm

By Tracy Hultin

[1]

[1]At the intersection of advanced technology and inclusive design principles lies a near-century-old invention called the custom-balanced door. Custom-balanced doors are intelligently engineered with accessibility and sustainability in mind. In addition, these doors are being incorporated into modern buildings with other smart technologies, such as touchless activation switches, electric strikes for card readers, and power operation systems, to enhance user experience and security.

A custom-balanced door is an ideal solution for oversized doors or those constructed from specific materials. This specialized door incorporates a balanced mechanism that minimizes opening effort by strategically distributing its weight. A larger portion of the door swings outward, effectively leveraging wind and air pressure to assist with opening, which is particularly advantageous in high-wind areas or high-rise buildings. A custom-balanced door is a bespoke door featuring integrated, precision-balanced opening mechanics, often allowing for customization of design and materials to meet specific project requirements.

Custom-balanced doors are also increasingly being specified for designs that require compliance with the latest version of Americans with Disabilities Act (ADA) standards and other universal design principles that ensure accessibility for everyone.

Understanding custom-balanced doors

Custom-balanced doors offer a unique solution for architectural entrances, balancing form and function. Unlike traditional doors, balanced doors are engineered to pivot around their center of gravity, which sets them apart from other types of doors. This design allows for smoother operation and minimal user effort.

In terms of operation, the fulcrum point of a balanced door is positioned at one-third of its width, which means one-third of the door leaf recesses into the building when opened. This arrangement creates a much more balanced pivot point, ensuring better weight distribution and fewer doors projecting onto a sidewalk, which is critical for busy city streets such as New York City. Despite the inset fulcrum, a balanced door does provide a similar opening space to conventional butt-, continuous-, and pivot-hinged doors.

Leading balanced door manufacturers also offer customization options that allow architects and designers to tailor these doors to meet specific project requirements, ensuring seamless integration into the building’s overall design and aesthetic.

[2]

[2]A quick history

The balanced door was invented in 1932 when Edward and Oliver Ellison recognized the need for a better door design. Entering what ended up being a five-year research and development process, the Ellison brothers had their sights set on delivering the most intelligent door design to date. Since taller and more tightly compressed buildings were becoming the norm, there arose a need for a door that could more easily overcome external wind pressure and internal stack pressure, among other benefits.

The design also needed to render the door size and weight inconsequential to ease of operation and longevity of service life. This combination of solid, durable materials paired with reliable, long-lasting performance would be the recipe for success for the world’s first balanced door.

Intelligently designed

A balanced door’s components work harmoniously together to ensure the doors open effortlessly and close reliably. Here are the core components:

Materials

Balanced door assemblies are available in various materials, such as formed bronze, formed stainless steel, extruded aluminum, wood, and tempered glass, offering both durability and timeless aesthetic appeal. Care must be taken to address the installation and co-ordination of the adjacent materials and frame and the verification of loads for the custom doors.

In terms of size and dimensions, narrow stile balanced doors feature thin stiles that are popular among architects to achieve a modern, sleek design. Slim 29-mm (1.15-in.) stiles are available in bronze or stainless steel. For architects and designers who prefer an even thinner stile, 25.4-mm (1-in.)-wide stiles are available on extruded aluminum doors.

Formed bronze and formed stainless steel balanced door dimensions may vary, but stile width minimums are typically set at 70 mm (2.75 in.) (89 mm [3.5 in.] preferred) with a minimum top rail height of 70 mm (2.75 in.) (89 mm [3.5 in.] preferred) and a minimum bottom rail height of 152 mm (6 in.) (254 mm [10 in.] recommended to comply with ADA standards). In most cases, the minimum face width of the frame material is 76 mm (3 in.) with frame depth at a minimum of 127 mm (5 in.); for these formed bronze and steel doors, glass and glass thickness may vary.

Extruded aluminum balanced doors have a similar structural appearance to formed stainless steel or bronze balanced doors, but with aluminum extrusions instead of formed metal. Stiles are internally fastened to the top and bottom rails during fabrication for these doors. Stile widths range from 63 mm (2.5 in.) to 114 mm (4.5 in.), with top rails usually measuring from 63 mm (2.5 in.) to 127 mm (5 in.). For the bottom rails, manufacturers aim for at least 152 mm (6 in.) but will make them taller (254 mm [10 in.] or greater) if protective dress plates are added to the bottom of the frame.

Tempered glass balanced doors are “all glass” doors that feature a top and bottom rail that secures the glass to the hinging mechanism. Rails can be made of stainless steel, bronze, or aluminum. Bronze and stainless steel rails are typically a minimum of 121 mm (4.75 in.) in height, and standard aluminum rails are between 121 mm (4.75 in.) and 254 mm (10 in.) in height for tempered glass doors. A 13 mm (0.5 in.) tempered glass is used for balanced doors from 2.4- to 2.7-m (8- to 9-ft)-tall, and 19-mm (0.75-in.) tempered glass on doors taller than 2.7 m (9 ft).

[3]

[3] [4]

[4]Torsion bar spring

The torsion bar spring provides the closing force for the door and is designed specifically for heavy doors and traffic. The shaft containing the torsion bar closer spring can be concealed or exposed within the formed bronze frame.

Check and guide channel assembly

Located in the frame header above the door, this component provides a path for the door’s closing and latching speeds. It contains hydraulic fluid and two valves to adjust speed to ensure smooth operation. As an added benefit for installers and owners, it allows for maintenance from the underside without removing the door, which is crucial when working with large and heavy doors. This item requires coordination for the custom door to ensure that all elements fit within the frame properly, considering the provided dimensions and structure.

Door roller guide

The roller guide in the top rail serves as the door’s fulcrum. It should be made with robust materials, such as cast manganese alloy housing, because it absorbs a shock when the door opens and closes. This component also features a sealed roller bearing that facilitates the smooth movement of the door by simply rolling along the guide channel it sits in.

Top arm and top pivot bearing

Found in the top rail, the top arm connects the top of the door with a 25.4 mm (1-in.) diameter stainless-steel pivot pin that sits in the top pivot bearing. Once assembled on the building, this connects the top of the door to the top of the shaft and finally to the top of the arm, supporting the lateral weight of the door’s top portion and rolling when the door opens and closes.

Bottom arm

The top and bottom arms are welded to a heavy-duty, full-height steel tube shaft that spans the entire height of the door. The bottom arm, located at the base of the door, is thicker and heavier than the top arm because it carries the weight of the frame. Both arms (top and bottom) feature four heavy penetration welds holding the shaft, giving the door long-term strength and durability.

Bottom pivot component

Unlike the top pivot bearing, the bottom pivot’s bearing is made of a plastic self-lubricating component to minimize corrosion. This is because the bottom bearing is more susceptible to contaminants (e.g. salt, snow melt, cleaning solutions, water, dirt, etc.) due to its location on the ground. The bearing at the top of the door is less exposed to these contaminants, so it is made of stainless steel. However, a stainless-steel pin is inserted into this portion of the bottom arm, allowing for operation.

This is another coordination item for the custom door, considering how elements fit in the proposed floor finishes for weight, accessibility, and floor structure considerations, as well as how much space is required for installation and the depth of the floor materials.

Floor box

The pivot shaft assembly of a balanced door sits on a 13-mm (0.5-in.) thick floor box base plate that spans from the interior to the exterior side of the door. The floor box is designed specifically not to rust or corrode and eliminates the need for a floor cutout. The weight of a balanced door is transferred down into this heavy-duty floor box.

These intelligently designed components create a balanced door system renowned for its longevity, strength, and durability.

[5]

[5]Meeting ADA standards

Balanced doors have become a go-to choice for architects designing ADA-compliant entrances.

According to the Pew Research Center, 42.5 million Americans have disabilities, which is approximately 13 percent of the civilian population.1 This statistic highlights the importance of designing entrances that adhere to ADA standards, which can be aided by the specification of custom-balanced doors. Not only is it a legal requirement in many circumstances, but designing to ADA standards is a fundamental step towards fostering inclusivity in public spaces, providing equal access to all individuals. This ensures everyone can easily navigate public spaces regardless of physical ability.

However, generally, the accessible guidelines are just that: guidelines. If adopted by a state, county, or city, they can become part of the code, and many jurisdictions have done that. Accessibility guidelines can be State or local adopted codes, A117.1 (IBC-based codes) or ADA standards for accessible design (for federal-based projects).

The most recent version of the ADA guidelines (published by the Department of Justice) was introduced on September 15, 2010. These revised, enforceable accessibility standards set minimum requirements for newly designed and constructed or altered state and local government facilities, public accommodations, and commercial facilities to be readily accessible to and usable by individuals with disabilities. The A117.1 has been updated from 2009 to 2017 with new requirements for clearances and turning dimensions.

Under the guidelines, at least 60 percent of common entrances must be accessible in new construction, including entrances directly serving tenancies, parking facilities, pedestrian tunnels, and elevated walkways. “Common entrances” include all entrances except those restricted or used exclusively as service entrances.

Additional requirements apply to transit facilities and entrances for inmates and detainees in judicial, detention, and correctional facilities.

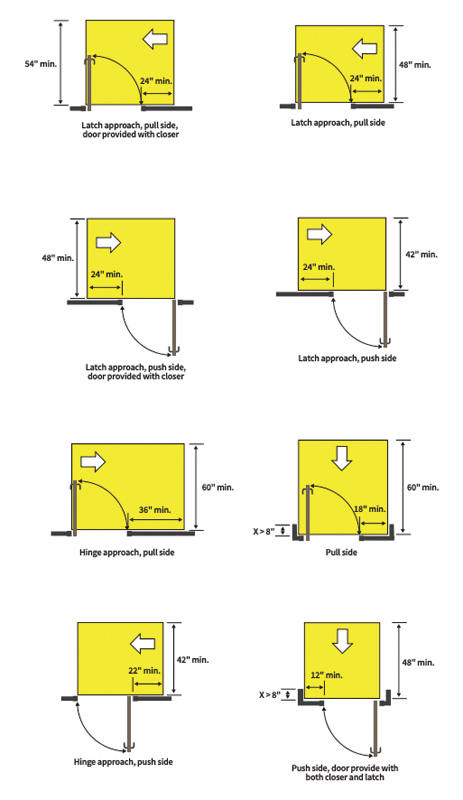

Regarding size, weight, and function, at least one door serving each accessible room or space must meet the prescribed entrance accessibility requirements. Figure 1 illustrates those requirements. Additionally, accessibility focuses on the weight in pounds (lb) to pull the door open at 2 kg (5 lb); this is the reason for using the custom-balanced door and the ease of opening these larger custom doors.

In addition, one active leaf of double-leaf doors is required to meet the criteria for clear width and maneuvering clearance. For designers, clear openings of doorways with swinging doors must be measured between the face of the door and the stop when open at 90 degrees. No projection into the clear width is permitted below 813 mm (32 in.), allowing those in wheelchairs to navigate doorways comfortably. This is especially critical in vestibule areas or ramps with limited maneuvering space.

Accessible guidelines are important for a host of other reasons:

- Inclusivity matters—Accessible compliance ensures entrances cater to the diverse needs of individuals regardless of their physical abilities. It goes beyond legality, promoting inclusivity and belonging in public spaces. Designers can specify balanced doors that are custom-made and designed to varying sizes and material types to meet accessible standards.

- Legal imperative—Failure to comply with accessible standards in areas that have been adopted into the building code not only results in legal repercussions but also hinders the goal of creating universally accessible environments. In fact, according to an article published by ADA Solutions, “an initial violation could set your business back as much as $75,000. Subsequent violations could be up to $150,000.”2

- Enhanced user experience—Accessible entrances contribute to an enhanced user experience for everyone. A well-designed entrance considers all individuals’ diverse needs, and it should be no more difficult to access for wheelchair users or those with mobility impairments than anyone else.

Leading manufacturers are offering custom-balanced doors designed as a complete system to meet the requirements of the accessible standards. By using balanced hardware, mounting locations, and integrated smart technology, including auto-operators and sensors, the doors ensure ADA compliance and integrate architecturally into a custom-designed entrance system that can last a lifetime with the proper maintenance.

Although not a standard integration yet, additional smart technology that can be integrated into balanced doors includes smart glass. In the future, the industry could see smart glass being used for specific applications or industries, relied on for its ability to change opacity and transparency for privacy and/or light control.

[6]

[6]Welcoming all

Designing universal entrances for accessible compliance is a multifaceted endeavor that must consider inclusivity and user experience, which should be a promise for all facilities accessible by the public. Manufacturers can be a key resource for architects, designers, and owners when educating and helping create accessible-compliant entrances.

Ultimately, the synergy between design, functionality, and accessibility of balanced doors is helping to create entrances that are both high-performing and aesthetically pleasing. Their continued specification by architects and designers will contribute to creating truly inclusive public spaces.

Notes

1 See the notes online at constructionspecifier.com/custom-balanced-doors

Author

[7]

[7]

Tracy Hultin is president and CEO of Ellison Bronze. Hultin joined the Falconer-based custom balanced door manufacturer in 2009 as national sales manager, then vice president of sales and marketing, and was elevated to president and CEO in 2021. With more than 25 years of professional experience working for custom door manufacturers, Hultin possesses a deep understanding of Ellison Bronze, its customers, and the architecture and design industry as it relates specifically to commercial doors and entrance systems.

Key Takeaways

Custom-balanced doors, a nearly century-old invention, blend advanced technology with inclusive, easily accessible design. Engineered for accessibility and sustainability, they are now integrated into modern buildings alongside smart technologies such as touchless activation, card reader electric strikes, and power operation systems to improve user experience and security.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/04/Jackson-Ryan-Architects-Market-Square-Tower-1170-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/04/Jackson-Ryan-Architects-Market-Square-Tower-1114.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/04/18-162-323.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/04/18-162-356.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/04/IMG_9849-Edit.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/04/Overhead-2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/04/Hultin_Headshot.jpg

Source URL: https://www.constructionspecifier.com/custom-balanced-doors-step-into-universal-design/