Designing with tornado-resistant glazing

by Katie Daniel | August 24, 2016 10:00 am

by Gantt Miller

Designing for unpredictable situations is one of the biggest and most important challenges for architects, engineers, and the building community. Tornadoes, hurricanes, and earthquakes are seemingly random, but can be devastatingly fierce when they arrive. In the face of such unpredictability, there are some things the industry can count on—improved products, more reliable third-party testing, and increasingly stringent building codes and standards. While hurricane and seismic products and code changes have been under development for many years, tornado mitigation is still in its infancy comparatively. What must a design professional know?

When designing a school or emergency facility in a high wind zone, the three most important questions are:

- whether appropriate products are available;

- how they fit into the budget; and

- whether they will work as expected.

Tornadoes were tossed into the spotlight with a vengeance following the twin occurrences in Joplin, Missouri and Tuscaloosa, Alabama in 2011. An EF-4 tornado tore through downtown Tuscaloosa on April 27, knocking out important emergency facilities, including the Emergency Management Agency, police and fire stations, and the city’s sewer and water treatment plants. Just weeks later, on May 22, an EF-5 Tornado hit Joplin, destroying the St. John’s Regional Medical Center (now Mercy) and nearly a third of the town, including homes, businesses, schools, and churches. The widespread destruction of these two cities has been called one of the deadliest tornado seasons in recorded history, and has served as a catalyst for renewed discussion about mitigation and risk assessment for the built environment.

Defense against tornadoes

While there are many products and strategies for hardening schools and commercial buildings against storm-related threats, the focus of this article is windows and glazing. The use of glass as a protective element against the horrific wind speeds of a tornado was once considered nearly impossible. Fortunately, advances in glazing science are causing a paradigm shift. Instead of designing underground concrete bunkers, architects can design rooms that can be used as emergency shelters during storms, yet still function as a usable part of the building the rest of the time. Public shelters no longer have to be isolated, crowded, and frightening.

Many schools, hospital emergency rooms, police/fire headquarters, and other public buildings are opting to include a safe room in their building design. This is much more cost-effective than hardening an entire building. Safe rooms or areas may serve as shelters for natural disasters, as well as intruder attacks. Since these spaces can also serve as workable space throughout the year, windows are an important element.

| THE DIFFERENCE BETWEEN TORNADOES AND HURRICANES |

|

Hurricanes are much larger than tornadoes. The largest tornado ever observed was Tornadoes, and the parent storm clouds that produce them, require strong vertical wind shear and strong horizontal temperature changes to form and survive. Hurricanes thrive in regions of weak vertical wind shear where the horizontal change in atmospheric temperature is small.* Strong tornadoes usually occur over land, while hurricanes almost always form over the ocean. Finally, the strongest tornadoes can have wind speeds of over 482 km/h (300 mph), but even the most extreme hurricanes rarely produce wind speeds over 321 km/h (200 mph). While tornado weather tracking and warning systems have improved significantly, there is still very little time to take action. For this reason, protection must be in place at all times, unlike in hurricane zones, where there is time to take preventive measures, such as pulling down shutters or installing plywood in front of glass doors and windows. When determining window protection for a tornado or hurricane, it is important to work with a window manufacturer who can specify the right product for the job. * For more information, visit www.hurricanescience.org/science/science/hurricanegenesis. |

Photos courtesy Winco Window Co.

Product availability

Thanks to the years of work done by manufacturers to develop hurricane- and blast-resistant products, almost all major window companies have the capability to develop high-performance glazing products. However, tornadoes perform differently than hurricanes, and there are special considerations that need to be taken into account, such as the way the window systems are set into masonry or concrete.

Most test labs can test tornado strength winds. However, availability of certified products according to the American Architectural Manufacturers Association (AAMA) is another story. Manufacturers have not yet started certifying their tornado-hazard-mitigating products, but Dean Lewis, AAMA’s technical manager, believes this could change as demand improves. For example, a manufacturer who offered 1220 x 1524-mm (48 x 60-in.) fixed windows at 6.22 kPa (130 psf) in 2009 has developed mulled 2185 x 2590-mm (86 x 102-in.) products at 12 kPa (250 psf) in the years since. Other companies are beginning to look at testing products for tornado resistance as the market opens up. When choosing a window manufacturer, one should seek out those with engineers who are knowledgeable about tornado, hurricane, forced entry, and ballistic and blast special load requirements for windows and anchorage systems.

AAMA 512 standard in place

One of the first standards to be put in place, AAMA 512-11, Voluntary Specifications for Tornado Hazard Mitigating Fenestration Products, uses existing test methods and other procedures to qualify specially designed windows and other glazed fenestration products for tornado hazard mitigation. The document provides a system for rating the ability of windows to withstand impact, pressure cycling and water penetration, which are generally associated with tornado conditions.

This standard does not specifically address use in residential structures and is not intended to reduce the need to take shelter during tornado events. According to Intertek Building Products, a major test lab facility, plans are underway to update the document to be more like the International Code Council (ICC) 500, Standard for the Design and Construction of Storm Shelters, for the next generations of the International Building Code (IBC) and International Residential Code (IRC).

[1]

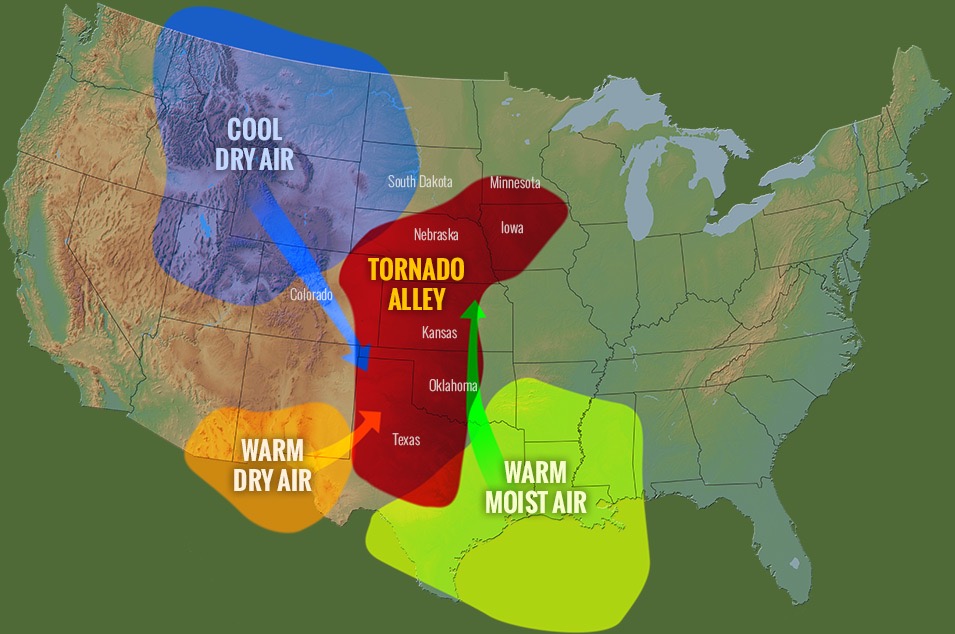

[1]Figure 1: International Code Council (ICC) 500, Standard for the Design and Construction of Storm Shelters, mandates storm shelters for certain geographic areas and certain building uses in the 402-km/h (250-mph) wind map zones – the region often thought of as “Tornado Alley.” This includes the plain states where cool/dry, warm/dry, and warm/moist air from neighbouring states meet to cause tornadic conditions.

Image courtesy U.S. Geological Survey

Understanding the ICC 500

ICC 500 is a standard for storm shelter design and construction and is adopted by reference in the 2015 IBC. It mandates storm shelters for certain geographic areas and certain building uses that are in the 402-km/h (250-mph) wind map zones (Figure 1). Those include critical facilities such as:

- 911 call stations;

- emergency operation centers;

- fire;

- rescue;

- ambulance; and

- police stations.

Group E occupancies, which include schools, must be able to accommodate the total occupant load of 50 people or more. Other facilities—such as hospitals, public stadiums, and arenas—must provide some form of tornado storm shelter.

Performance requirements for storm shelters far exceed normal building code requirements. Different criteria must be considered since the majority of adjacent non-shelter structures may be destroyed or damaged during an extreme wind event. The building envelope may be perforated by windborne debris, adjacent taller structures, objects collapsing onto the shelter, and vehicles rolling over. It is critical a continuous load path from all shelter components to the supporting foundation is designed.

| NEW ST LOUIS COUNTY EMERGENCY CENTER LINKS FIRST RESPONDERS TOGETHER |

|

With the strength of a bunker, but the appearance of an ordinary office building, the new St. Louis County Emergency Management Center ensures better management of incidents through the rapid sharing of information among firefighters, emergency medical services (EMS), police, hospitals, public works, and other groups—functions previously housed in many separate facilities across St. Louis. Considering the operational function of the building, it was imperative to make the building envelope impenetrable to natural disasters and blast/ballistics attacks. The cast-in-place concrete, single-story administrative structure with interior steel framing and a concrete deck is wrapped with a brick veneer. The 91-m (300-ft) long façade and 8-m (27-ft) wall housing the main technological component of the building feature strategically placed architectural-grade pre-glazed window systems, designed to withstand 289-km/h (180-mph) winds with an impact from a 6.8-kg (15-lb) 2×4 traveling at 160 km/h (100 mph). Additionally, silicon sealants and tape ensures water does not penetrate. The natural daylight provided by the windows allows staff to work in a somewhat typical workplace environment. The facility is designed to stay in operation for three days on its own power, and is anticipated to be able to survive tornados, earthquakes, and other disasters. |

FEMA provides storm shelter guidance

Another resource for architects and specifiers is the U.S. Federal Emergency Management Agency (FEMA) P-361, Safe Rooms for Tornadoes and Hurricanes: Guidance for Community and Residential Safe Rooms. A shelter is typically an interior room, space within a building, or an entirely separate building, designed and constructed to protect its occupants from tornadoes or hurricanes. Shelters are intended to provide protection against both wind forces and the impact of windborne debris. The level of occupant protection provided by shelters is intended to be much greater than the protection provided by buildings that comply with the minimum requirements of building codes.

Model codes provide life-safety criteria and, until recently, tornado resistance was not part of the IBC. Various states have begun to incorporate “enhanced protection” criteria into their codes, defining requirements for community safe rooms for Risk Category 3 and 4 structures. Most notable of these is the Sunshine State with its 2014 Florida Building Code.

As posted on the FEMA website:

When safe room designers, operators, and emergency managers implement FEMA’s Recommended Criteria in their projects, they can feel confident that they are using the best available information to guide the design and construction of a safe room (public or private) that provides near-absolute protection from the deadly winds and wind-borne debris associated with extreme-wind events. Additionally, if the safe room is being constructed with FEMA grant funds, adherence to the FEMA Recommended Criteria publication is required.

According to FEMA, there has never been a reported failure of a safe room designed to these standards.

Addressing cost concerns

According to John Farnen, Mercy Hospital Joplin’s vice president of planning, design, and construction, upgrading the new building to a state-of-the-art level of protection added about two percent above its standard design criteria to the total cost of building a new facility. There really is not a code for the construction of an overall hospital. ICC 500 applies to certain aspects, but not an overall assembled facility. For example, the windows meet that standard, but there is no overall rating on the entire exterior. However, Mercy used concrete exterior precast siding, which by itself survived the storm. Mercy mainly took the lessons learned from its existing hospital, considering which materials held up through the storm and tried to use them in the design of the new facility. The designers feel the additional two percent investment was worth it, as life safety is protected and patients can be cared for before, during, and after the storm.

When the many benefits of tornado-resistant glazing are fully taken into consideration, the cost of the project becomes more reasonable compared to standard impact window installation.

Product development

Hurricane-resistant windows are typically made with laminated glass, and can be fixed or operating windows. Tornado-resistant windows are typically fixed windows that incorporate a thick polycarbonate impact layer either through the use of glass-clad polycarbonate infill or as a separate impact barrier built into a secondary panel. They differ from hurricane-resistant windows via the specifications used for their testing. Hurricane-resistant windows use wind charts from American Society of Civil Engineers/Structural Engineering Institute (ASCE/SEI) 7, Minimum Design Loads for Buildings and Other Structures, while tornado-resistant windows use wind charts from the aforementioned FEMA P-361 (both charts are in ICC 500).

The development of tornado-resistant glazing has benefitted from the research and development that went into hurricane products, despite the contrasts in the two high-wind events’ power and duration. (See “The Difference Between Tornadoes and Hurricanes.”) Hurricane-resistant windows typically undergo a structural test at 150 percent of design load while tornado-resistant windows, due to the very short duration of a tornado event, undergo a structural test at 120 percent of design load per ICC 500. (ICC 500 and AAMA 512 only specify a 120 percent structural load to be consistent with each other, but hurricane windows, given their prevalence in the marketplace, typically get tested to 150 percent structural load to remain consistent with other window certification requirements.)

Tornado impact products are also different from hurricane glazing. A hurricane test for windborne debris involves firing a 4-kg (9-lb) 2×4 missile traveling at 55 km/h (34 mph) or, per ASTM E1996, Standard Specification for Performance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Windborne Debris in Hurricanes, at 86 km/h (55 mph). In a tornado test, a 6.8-kg (15-lb) 2×4 missile is fired at up to 160 km/h (100 mph). Tornado-resistant glazing can also offer other enhanced performance attributes such as blast/ballistic resistance, acoustics, and thermal/solar control.

Seeking government grants

In some cases, federal money may help partially fund projects. According to Intertek’s Jeff Robinson, there are two main types of FEMA grant programs for tornado resistance:

- Hazard Mitigation Grant Program (HMGP); and

- Pre-disaster Mitigation (PDM ) Grants.

The pool of money and eligible communities for HMGP funding are specific to a given “Declared Disaster.” In general, once the gross non-insured cost of a disaster is calculated, and if the U.S. president has included language “reducing the cost of future disasters” in the disaster declaration, a percentage of the uninsured costs are automatically allocated for HMGP projects. When a disaster strikes and HMGP funds are going to be made available, there will be a specific 90- to 180-day window in which a Notice of Funding Availability (NOFA) is open. A project must be submitted during an open NOFA to be eligible for funding. Applicants can be either public or qualifying public non-profit organization.

PDM grants generally run in annual cycles, are not based on having been affected by a specific disaster, and are nationally competitive. The funding for this pool of money is generally set by Congress and has been reduced over the past decade.

Architectural or client teams may call their State Emergency Management Office and ask whether there are any NOFAs open or upcoming, or any additional grant programs that could help fund their mitigation project or initiative. FEMA provides the money to the state, which in turn, processes grant applications and also allocates the money for the actual projects.

Looking forward

As coastal architects and builders can attest, developing new products for hurricane resistance was a long and often contentious process. However, Florida is now widely admired for its protective building codes and has been a model for many states and even other countries. In other words, while tornado resistant glazing may not be at the top of everyone’s short list, it is comforting to know products, processes, and codes are now in place.

| THE TORNADO AT MERCY HOSPITAL |

|

Mercy Hospital Joplin made headlines for the massive destruction after a devastating EF-5 tornado destroyed the entire structure in 2011. The hospital again made headlines when it was rebuilt to the toughest standards its design team could create. Patient safety was top priority, with the ability to operate normally during and after a storm. To evaluate the best path forward, the team studied the destruction of the original building. Almost every window was blown out, except for one area in the hospital. The windows in the Behavioral Sections area of the hospital were made from laminated glass and remained intact. Realizing that these high-performance windows could help, the team studied lessons learned from hurricane zone window performance. Since tornadoes have much higher wind speeds and traveling speeds than hurricanes, different criteria were developed and tested. Today, the new Mercy Hospital Joplin has windows that can resist up to 402-km/h (250-mph) winds in patient-critical areas and 225-km/h (140-mph) winds where patients can be temporarily moved |

Gantt Miller is the chair of Winco Window Company. He led the American Architectural Manufacturers Association (AAMA) task force to create a new voluntary specification, AAMA 512-11, Voluntary Specifications for Tornado Hazard Mitigating Fenestration Products. Miller has been a part of 50 different committees and task groups during the decade that he has been active in AAMA and has served as a co-chair on five of these committees. He is the former chair of the AAMA board of directors, and continues to serve in numerous other groups and roles involved in guiding the day-to-day operations of AAMA. Miller can be reached at ganttmiller@wincowindow.com[2].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2016/08/Figure1-1.jpg

- ganttmiller@wincowindow.com: mailto:ganttmiller@wincowindow.com

Source URL: https://www.constructionspecifier.com/designing-with-tornado-resistant-glazing/