Ensuring effective custom HVAC assemblies

by Katie Daniel | April 11, 2016 3:06 pm

by Brian Fiegen

As many designers can attest, selecting the most appropriate HVAC system involves more than an off-the-shelf purchase. Designing a mechanical system for maximum energy efficiency, reliability, serviceability, and sustainability—while meeting the varying usage needs of the customer—requires broad expertise and a thorough understanding of key considerations in system design. Having the right team and leveraging design resources and tools, including utilizing HVAC manufacturer applications experts, are important elements in selecting a system suited for customer needs and application requirements.

Many details in the design and operation of the system can have an impact on its performance. While the upfront cost frequently dominates the decision-making process for customers in designing an HVAC system, other important considerations should include ongoing efficiency savings, lower lifetime maintenance costs, service requirements, and performance.

Other factors influencing the design may include hours of system operation, ambient conditions, utility rate structure, and mission-critical reliability requirements. Understanding how these factors impact system requirements and design is critical to the process.

Resources to aid in the decision process

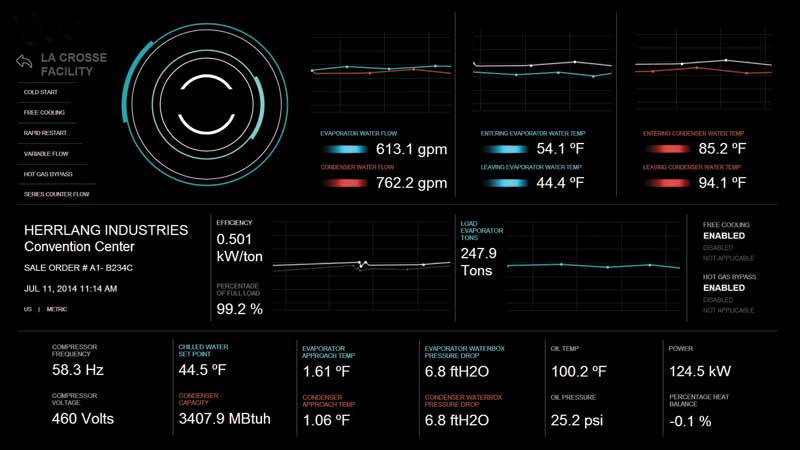

Energy modeling and building simulation tools that compare the performance of system options are among the most powerful instruments engineers have to help make system design decisions. For example, advanced and comprehensive load design and energy analysis software can provide design-sizing and building-load profile information such as peak and hourly loads to begin the equipment-sizing decision-making process.

Analyzing a building load profile provides insight into the preferred system configuration options for consideration. Creative system options such as asymmetrical system design or thermal storage may become potential options. Once the selected options have been identified, building simulation can begin.

The output from this work includes information such as energy consumption and demand by system element, which allows the designer to know what to expect with each building design variation and the implications it will have on building performance. With this additional insight, derivatives of the selected options can be considered and modeled.

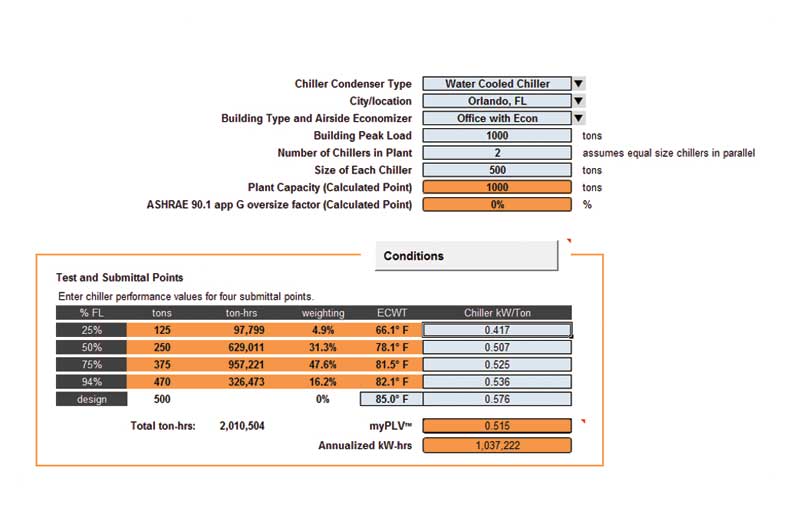

Sometimes this work is too lengthy and costly, particularly early in the design process when scoping and concept work is the goal. In these situations, an engineer can utilize simpler or narrower-focused tools. One example is a chiller plant analyzer. This tool allows the engineer to focus on the chiller plant without the distractions of the detailed building elements.

Preferred system configurations can be quickly assessed for concept selection purposes. These selected options can then be carried forward to the full building simulation work appropriate for later in the design process.

Finally, there are times when specific equipment decisions need to be made quickly and objectively. In these situations, online manufacturer-agnostic tools help engineers and building owners quickly and accurately estimate chiller energy usage and costs. The predictive software value and economic payback calculated reflects the chiller plant’s design, installation location, and building purpose while avoiding the more in-depth and costly process of a full building energy simulation model.

There is every reason to turn to objective evaluation methods to make sound system solution decisions. Valuable tools exist for multiple points in the design process and for various levels of detail necessary to meet the needs of most jobs.

Benefits of working with HVAC design experts

In addition to design and analysis tools, another important step aiding engineers and building owners in selecting the most appropriate HVAC system is tapping into the knowledge and expertise of manufacturer experts who work with various systems and bring focused knowledge when judging which will be most appropriate for a specific application.

Working together with engineers and owners on a project, HVAC manufacturer applications experts can provide leadership and expertise in mechanical system’s design and evolving code requirements and standards. Involved in a multitude of projects and a myriad of applications all across the country, such experts have unique perspectives to make recommendations based on collective experiences and best practices.

HVAC applications experts can also help identify how changes in building usage and needs may affect performance in the future, and how best to provide and implement a resilient design. They bring a deep understanding in applying various technologies to projects. From high-level scoping tools, to more detailed analysis tools and building energy simulation, applications experts can assist with evaluation of technology options at any point in the design process—and then help customers use those tools.

System expertise

With evolving customer needs, it is often hard to navigate through the broad range of varying technologies that can provide individual benefits but may not work well together. The deep understanding and expertise in using various technologies is another benefit HVAC manufacturer applications experts bring to a project. They can help building owners achieve energy savings without spending money in unnecessary ways.

For example, heat recovery and variable-speed drives on centrifugal chillers are two technologies offering significant value to customers. However, they are two technologies that do not pair well together. Variable-speed drives improve centrifugal chiller performance when condenser temperatures can be reduced, but heat recovery applications typically demand higher condenser temperatures. Therefore, these two energy-saving technologies tend to ‘fight’ each other.

Not all system experts have the same level of industry expertise, knowledge, and leadership. This is another consideration to keep in mind when choosing a manufacturer’s system applications expert as a design partner for a project. To identify a trusted expert, it is important to look for engineers that focus on HVAC systems and their application as a core part of their job, that frequently work with consulting engineers, and are respected, active participants in non-profit industry associations like ASHRAE.

Who can benefit?

Working with HVAC system design experts can bring value to projects of all types and sizes. Generally, more sophisticated systems—like those found in healthcare and industrial applications—receive the most value and return on investment (ROI) from leveraging experts. In one recent example, a hospital located in a northern climate was planning to replace four old air-cooled chillers in an effort to improve system efficiency.

In the first phase, the hospital was replacing two of the chillers with higher-efficiency models equipped with variable-speed drives. Working with an HVAC manufacturer applications expert led the hospital to be open to exploring thermal energy storage as a technology to reduce the demand-based portion of their utility bill.

After studying various options, the hospital arrived at a solution using two smaller air-cooled chillers paired with nine ice storage tanks. This earned the hospital a $332,000 utility rebate and resulted in a projected $65,000 annual utility bill savings. The plant was also designed for an easy chiller and ice tank expansion for the second phase of the plan.

In another recent example, an industrial operation in a southern climate was planning to perform a regular overhaul shutdown of their production line. Process cooling is a fundamental part of the production line—operating continuously and thereby requiring constant cooling. The company was looking for opportunities to make changes to reduce energy use during its short shutdown period.

Cooling towers simultaneously supplied water of a constant temperature directly to a process for cooling and to the condensers of chillers providing additional process cooling. The ability to supply an optimized water temperature to the chiller condensers would reduce the system energy use, but the direct process cooling needs could not accept a varying water temperature.

Capital was tight, and after studying various options, they arrived at a cost-effective solution that separated the direct cooling system from the chiller-heat-rejection system, allowing independent temperature control of each heat rejection system. As a result, the chilled water system was able to realize the benefits of optimized control of its condenser water temperature without compromising other parts of the process. This solution was a result of detailed discussions with the chiller manufacturer’s system experts.

However, the efficiencies and benefits that HVAC manufacturer system experts can offer are not limited solely to large systems. They also have expertise helpful with packaged solutions for smaller applications.

Experts can help maximize system benefits

With increasing performance demands on HVAC systems, new technologies are quickly evolving. For example, some systems can greatly improve building energy use even as the indoor air quality (IAQ) and acoustic expectations have changed over time.

Factory-testing HVAC systems and equipment is becoming common practice for customers; it should be considered to ensure the desired performance is achieved as specified. This is another way to leverage the knowledge and experience of HVAC manufacturer experts.

Given the complexity of mechanical systems and the investment companies and organizations make in them, the importance of leveraging the leadership and expertise of industry experts can be critical to the performance and efficiency of the system. There is great value in picking the right system, understanding how it works (and why it was designed that way), and controlling it for optimized performance, reliability, and efficiency. Equipment manufacturer system experts can bring focused expertise, specialization, and their knowledge to the table, helping customers maximize the system to suit the project’s specific needs and building usage.

Brian Fiegen is the systems applications leader for Trane in North America, Europe, and the Middle East. A 32-year industry veteran, he has held numerous product management positions while leading the development and promotion of air-handling and distribution products, systems and controls. Fiegen is a member of the American Society of Heating, Refrigeration, and Air-conditioning Engineers (ASHRAE). He can be reached at bfiegen@trane.com[1].

- bfiegen@trane.com: mailto:bfiegen@trane.com

Source URL: https://www.constructionspecifier.com/ensuring-effective-custom-hvac-assemblies/