Harnessing concrete masonry for climate-friendly buildings

by arslan_ahmed | February 2, 2024 8:00 pm

[1]

[1]By Mark D. Hagel, PhD., P.Eng, Mike Lafontaine, CTR., SSG., SD

Hollow concrete block masonry was first used as a building material around 1870, when wooden molds were developed to produce concrete block units from a relatively dry mixture of sand, cement, and water. Around 1900, the first cast iron block producing machine (Figure 1) was patented and a decade later, there were more than 1,000 producers of concrete block in North America.

In current construction, concrete masonry units (CMUs) are used as both structural and architectural building materials. CMUs are ideal candidates for carbon dioxide (CO2) sequestration because they are porous and carbonate quickly when left exposed to the atmosphere (weathering carbonation) and can also be cured with CO2 in a closed chamber with either low-pressure or high-pressure steam (pre-carbonation). For CMUs, CO2 absorption by mass of cement binder is roughly 6.3 percent. This translates to approximately 0.250 kg (0.5 lb) of CO2 sequestered per standard 198 mm (7.8 in.) hollow CMU. The carbonation of concrete masonry is not only environmentally friendly, but it can also achieve higher early strength.

Concrete block masonry and architectural block masonry also support resilient buildings. The more extreme weather events being experienced throughout the world can be mitigated with concrete masonry as it is fireproof, highly impact-resistant, and can store moisture without degradation. A fireproof material provides resiliency against forest fires, while the high impact- resistance protects against hail damage and impact damage during high wind events such as tornadoes.

[2]

[2]Concrete masonry’s ability to store water provides resiliency against floods and can also reduce water loads on stormwater systems when used as veneers. Concrete masonry can absorb more water during heavy rain events than siding or glazing, which shed water to the ground and storm drains. They can absorb water without degradation to the cladding. Although there is no lab testing for resiliency against floods, there are decades of proven performance where concrete block does not mold, rust, or rot. The location of the rebar, when fully grouted, provides adequate protection for a single wythe masonry wall, 95 mm (3.7 in.) of concrete cover for rebar, and is typically protected by an air vapor barrier that is highly resistant even to standing water.

Achieving more climate-friendly concrete masonry involves reducing the amount of embodied carbon, as well as the amount of operational carbon in the buildings constructed with concrete block masonry. Embodied carbon is the carbon emissions resulting from the extraction, manufacturing, delivery, installation, and disposal of the product. Operational carbon creates emissions resulting from the use of the building, such as HVAC, lighting, and power. With concrete masonry, substituting Portland Limestone cement (GUL) for General Use Portland cement (GU) in the manufacture of concrete masonry products and accelerating carbon sequestration by pre-carbonation can reduce embodied carbon emissions. Operational carbon can be reduced by taking advantage of the thermal mass effects of concrete masonry. This improved thermal modeling creates concrete masonry assemblies that mitigate the loss of thermal energy and reduce the amount of heating or cooling a building requires during operation.

Concrete masonry can be used to create backup walls and claddings that can meet the requirements of net-zero energy building envelopes, eliminating operational carbon from heating. Their long service life requires little maintenance and offers an even better carbon footprint when the embodied carbon and operational carbon are amortized over the life of the building. These products are cradle-to-cradle rather than cradle-to-grave, as concrete masonry is 99 percent recyclable at the end of service.

This article will explore Environmental Product Declarations (EPDs) currently available for concrete masonry products and carbon sequestration of concrete masonry units in weathering carbonation and pre-carbonation of CMUs. The article will also explore achieving net-zero energy buildings (passive house) by introducing improved values to more accurately account for thermal bridging in concrete block-brick veneer walls. It will also explain the use of a low-rise concrete masonry building achieving the net-zero energy requirements for opaque and fenestration and doors of passive house.2 The article will conclude with the benefits of the thermal mass effects of concrete masonry on reducing operational carbon.

EPDs for concrete block

An EPD is a document that communicates the environmental impact of any product or material over its lifetime. In the construction industry, EPDs support carbon emission reduction by providing comparisons of the impact of different materials and products to select the most sustainable option. Architects, engineers, and designers can choose the most sustainable option for their project, while manufacturers can optimize the impact of their products and market their carbon transparency. An EPD is usually valid for five years and is generated according to ISO 14040/14044, ISO 14025, EN 15804, or ISO 21930 standards.3

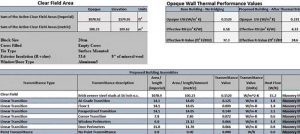

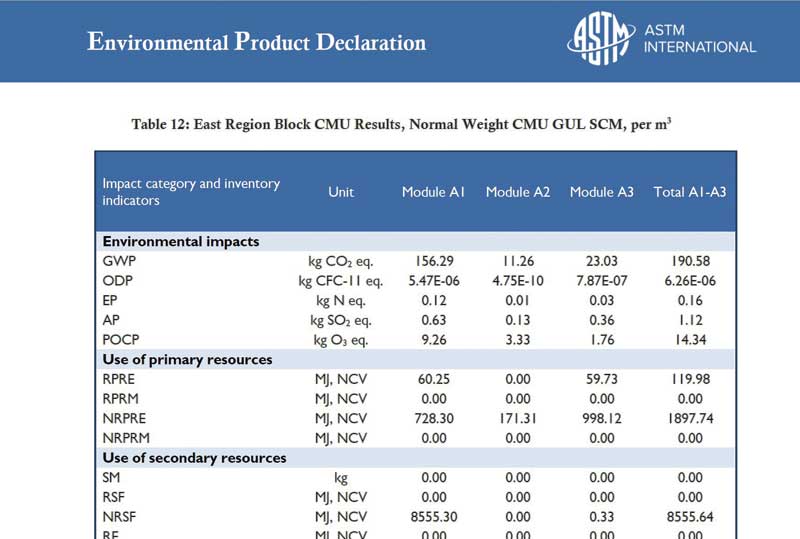

EPDs can be nationally averaged or plant-specific. Plant-specific EPDs provide more points in the LEED certification system as they are regarded as more accurate than nationally averaged EPDs. EPDs for concrete masonry products are also now available. Figure 2 provides an excerpt from the Canadian Concrete Masonry Producers Association’s (CCMPA’s) nationally averaged EPD3 for Eastern Canada producers with an averaged global warming potential (GWP) at 205.38 kg (452 lb) of CO2eq when using GU Portland cement to manufacture the normal weight CMUs; while Figure 4 provides the Eastern Canada producers averaged GWP at 190.58 kg (420 lb) of CO2eq when using GUL to manufacture the normal weight CMUs. From these values, it can be seen as the substitution of GUL for the GU cement in the manufacture of concrete block products resulting in a 7.7 percent reduction in the GWP of concrete masonry products.

Carbonation of CMU

There are two methods showing how CMUs absorb CO2: weathering carbonation and pre-carbonation (carbon curing).

Weathering carbonation occurs as concrete, used to manufacture the concrete block, and the mortar joints used to assemble a block wall, mature due to the reaction of CO2. This happens when moisture is present with the hydrants (i.e. alkalis) in concrete block, mortar joints, and grout. Specifically, CO2 from the atmosphere diffuses into the capillary pores and combines with the water to form carbonic acid.3 The rate of CO2 diffusion depends on the relative humidity (RH); it is most rapid between 65 and 75 percent ambient RH.

Carbonic acid then reacts with the hydrants—such as solid calcium hydroxide, calcium silicate hydrate (C-S-H) gel, and alkali/calcium ions in pore solutions—to form carbonate. Generally, calcium hydroxide has the highest concentration in Portland cement concretes and mortars.

Both mortar and CMUs, being more porous than cast-in-place concrete, experience higher rates of carbonation. In dense concrete, for example, penetration may be less than 20 mm (0.78 in.) after 50 years. With the mortar in the joints of masonry structures, indicator tests have demonstrated carbonation of a 10 mm (0.3 in.) thick by 90 mm (3.5 in.) deep mortar joint is substantially complete after less than a decade.

A recent study by the Concrete Masonry and Hardscapes Association (CMHA) for ASTM discovered that a 198 mm (7.8 in.) concrete block will be 25 percent fully carbonated within 28 days of manufacture and 49 percent within

26 weeks of manufacture (Figure 4a and 4b).4 Although current life cycle analysis (LCA) does not account for carbon sequestration of concrete masonry products due to weathering carbonation in the GWP value, it will likely be included in the near future once more accurate methods of estimating weathering carbon sequestration by concrete masonry products are established.

Pre-carbonation of concrete masonry products occurs by either using CO2 to cure the units at the time of manufacture or by using cement powder that has been pre-carbonated to manufacture the units. When CO2 is used to cure the units, CO2 sequestered from the atmosphere is introduced into the curing process of autoclaved CMUs. Autoclaved concrete blocks are steam-cured in a high pressurize vessel—it is a process that can easily integrate CO2 into the steam curing process. In Figure 5, an existing autoclaving chamber is in the process of being modified to include CO2 curing into the manufacture of CMUs (Figure 6).

Pre-carbonation typically increases the early strength of the CMUs and reduces shrinkage and defects in the finished units. These higher, early strength gains can allow for producers to reduce their cement loading, further reducing their CO2 footprint.

Pre-carbonation technologies have the potential to reduce CO2 emissions associated with manufacturing concrete blocks, pavers, and segmental retaining walls by up to 35 million tons (31 million tonnes) per year in North America.

Achieving thermal performance and meeting net-zero building envelope targets

Building operations are estimated to contribute 28 percent to GHG emissions.5 Canada’s cold climate results in many days per year that buildings must be heated for occupant comfort and building performance. A thermally efficient building envelope can result in a significant decrease in heat lost through the envelope and corresponding reduction in the heat input from HVAC required to maintain occupant comfort. Even with high-efficiency HVAC systems, a thermally efficient envelope significantly reduces GHG from heat energy.

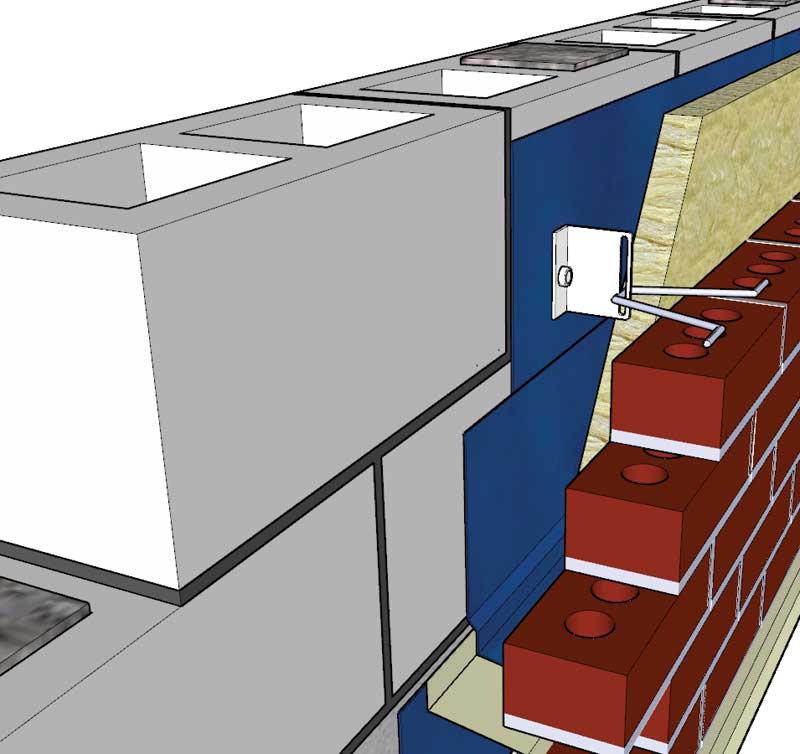

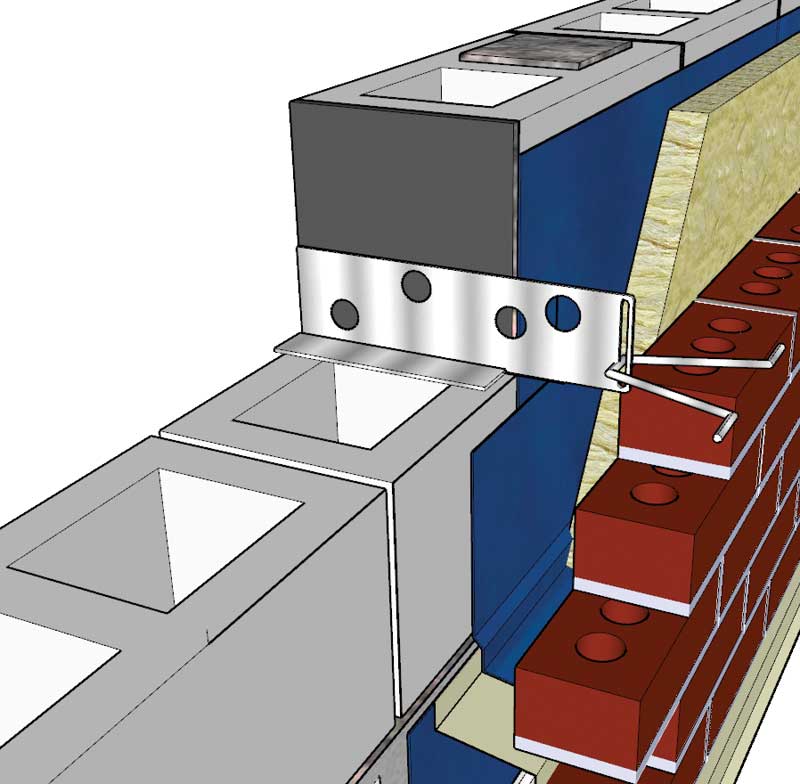

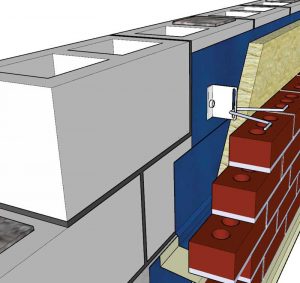

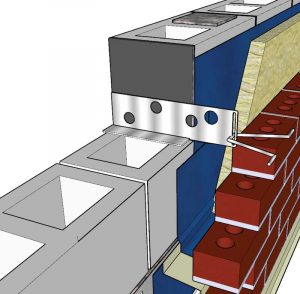

Canada’s commitment to reduce CO2 emissions has led to a target of net-zero energy (NZE) or passive house requirements for all new buildings by 2030. CMUs can be used to create building envelopes that achieve net-zero energy building requirements and help reduce the carbon footprint from building operations. When trying to achieve a thermally efficient envelope, it is important to ensure accurate thermal values and the latest technologies are being used for the thermal modeling. For example, using surface-mounted brick ties (Figure 7a) rather than embedded brick ties (Figure 7b) can increase the thermal performance of the wall by R-4.2. Currently the online thermal catalogs6 only have thermal values for concrete block backup walls with embedded brick ties.

Knife plate standoffs at the foundation (Figure 8) and at floor levels can also be used to increase the thermal performance of the wall by R-4.

The use of vermiculite or other insulation to fill the empty cores can increase the wall performance by R-4 as well. However, if these details are implemented in the construction, but are not captured by the thermal modeling because a thermal value cannot be readily found by the modeler, additional insulation without benefit will likely result.

The additional insulation, if unnecessary, can be detrimental, as it can increase the embodied carbon of the building by using more material than necessary to achieve the thermal target. It is estimated that 11 percent of CO2 produced globally is by building construction and materials. When the insulation being used is extruded polystyrene (XPS), expanded polystyrene (EPS), or sprayed polyurethane foam (SPF), the impact is amplified. These products are fossil-fuel based, so not always recyclable, and can take years to break down in landfills.

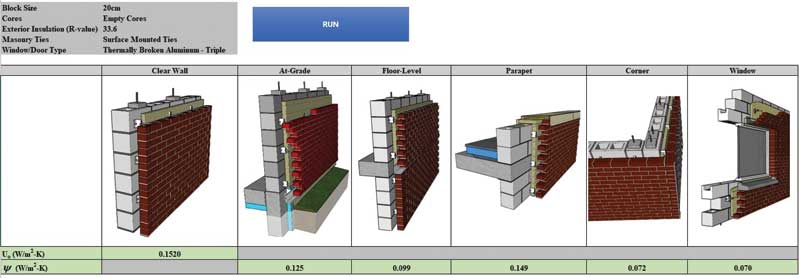

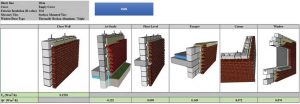

In partnership with the University of Alberta, thermal values were obtained and placed into a spreadsheet application (Figure 9) that captures items not currently found in the online thermal catalog and increase the accuracy of thermal models for wall assemblies using CMUs. This masonry thermal catalog application can be used to complement the existing comprehensive online thermal catalog.

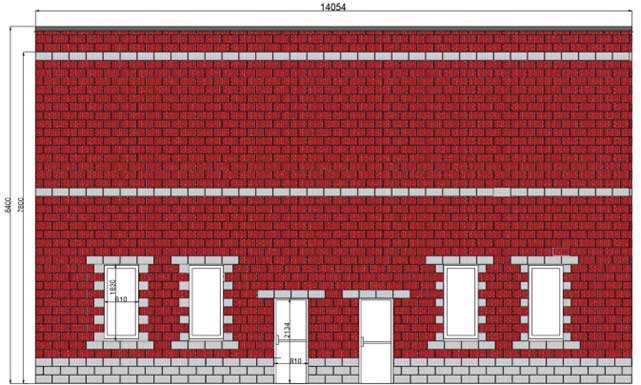

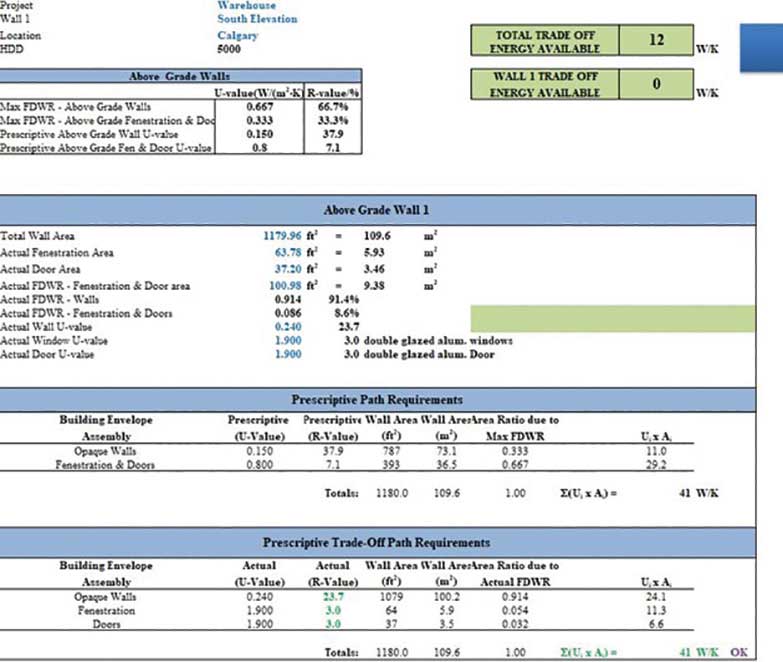

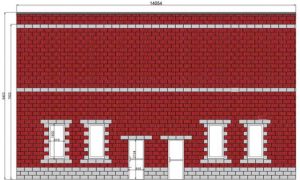

Another method to improve thermal efficiency in the envelope is to reduce the number of windows and doors (glazing) and increase the amount of opaque wall, resulting in a decrease in the fenestration and door-to-wall ratio (FWDR). It is easiest to illustrate achieving a net-zero energy building for the opaque wall required for passive house standards with an example of a single elevation of a brick veneer with a CMU backing on a two-story warehouse/office. Figure 10 provides a 3D rendering of a hypothetical two-story warehouse/office building located in Calgary, Alberta.

Figure 11 provides the 2D details for the front elevation of the building. The relevant dimensions of the building are as follows: 14 m (46 ft) long, 7.8 m (25 ft) tall at the roof transition, with a 0.6 m (1.9 ft) parapet. There are four 1.83 x 0.810 m (6 x 2.6 ft) windows and two 2.13 x 0.810 m (7 x 2.6 ft) doors on the front elevation.

To achieve passive house (net-zero energy building) requirements, Passive House Canada recommends a target of 0.15 W/m2 K (R-37.8) for opaque walls and 0.8 W/m2 K (R-7.1) for windows and doors.3

When using a concrete block with a brick veneer, two steps are required. The first step is a reduction in the opaque wall insulation demand for using a low glazing ratio that is typically associated with low-rise masonry warehouse and light industrial buildings.

Using a low glazing ratio benefits the overall performance of the wall system. The thermal requirements for fenestration and doors, even by Passive House standards, are five times worse than that of opaque walls. Therefore, a fully opaque wall with a lower insulation value, say R-22, will typically have an equivalent or better performance than a wall that has R-37.8 (0.8 W/m2 K). This applies to an opaque assembly at the maximum 33 percent FWDR permitted (based on the Heating Degree Days [HDD]) in many parts of Canada when using fenestration and doors at R-7.1(0.15 W/m2 K).

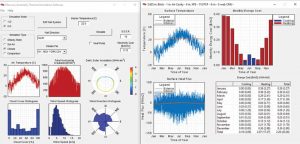

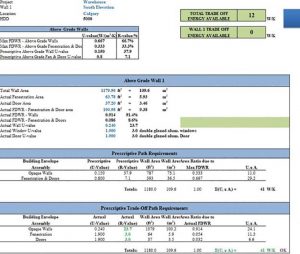

There is a prescriptive trade-off method developed by the National Energy Code for Buildings (NECB)5 that captures this and allows a proposed assembly to be designed and constructed—but only if an equivalent or less amount of heat energy is lost by the proposed assembly than the prescriptive requirements for an elevation of the same dimensions at maximum permitted FWDR. Figure 12 illustrates the calculations using the NECB prescriptive trade-off method, but with the net-zero targets of 0.15 W/m2 K (R-37.8) and 0.8 W/m2 K (R7.1) for opaque walls and for windows and doors respectively on the front elevation in Figure 11. The result of the calculation is a wall that loses 41 W/K of heat energy, which matches the prescriptive requirements for a 33 percent FWDR wall with R-7 and R-38 opaque walls, but used R-3 triple glazed thermally broken windows and doors and requires only R-23.7 from the opaque walls.

[3]

[3]The second step is accounting for thermal bridging of the opaque wall at horizontal linear transitions such as at-grade, floors, and roof transitions, at vertical transitions, at corners, and around windows and doors. Accounting for these bridging effects reduces the clear field value of the opaque block-brick veneer wall and provides a more realistic estimate of the thermal performance of the wall assembly.

[4]

[4]These results can be found in Figure 13 and use the thermal bridging values from Figure 9 in its calculations. In Figure 14, 203 mm (8 in.) of mineral wool is used as external insulation, providing a clear field R-value of the opaque assembly of R-37.3. The clear field R-value of the opaque wall is reduced by thermal bridging effects to R-24.6. However, the target R-value for the opaque wall assembly after trade-off (because of the low FWDR) on this elevation is only R-23.7, so the proposed opaque wall assembly is acceptable. Therefore, this concrete block wall assembly for the opaque walls has met passive house requirements for net-zero energy construction on the front elevation of this hypothetical warehouse/office building located in Calgary.

Thermal mass of CMUs

Thermal mass is a material property that describes how a material absorbs, stores, and then gradually releases heat energy.5 Buildings constructed with CMUs for the back up wall, the veneer, or both, have an energy-saving advantage because of their inherent thermal mass which allows CMU walls to absorb heat energy slowly and hold it for longer than less dense building materials.

Thermal mass results in fewer spikes in the heating and cooling requirements because the mass of the components slow the response time and better moderate indoor temperature fluctuations. In climates that experience large daily temperature swings, thermally massive buildings use less energy. This is in comparison to a low mass building of similar size due to the reduced heat transfer through the massive wall components. Thermal mass typically shifts energy demand to off-peak time periods.

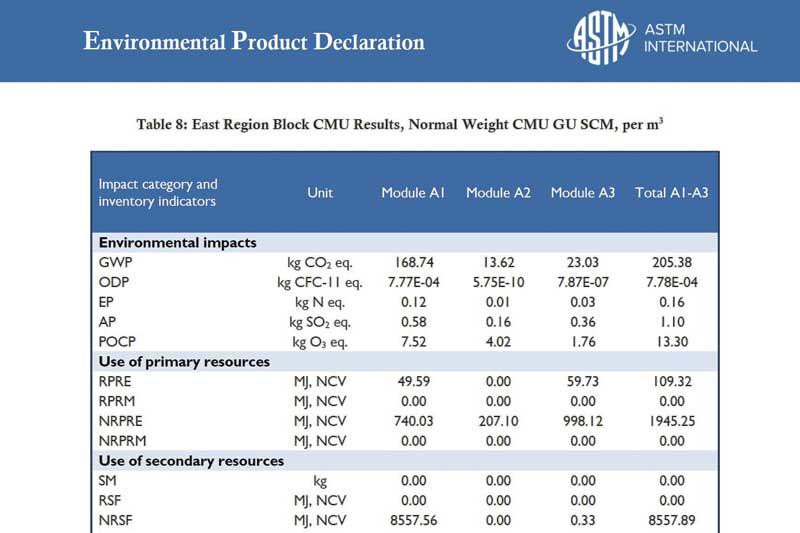

In the U.S., the COM CHECK system permits thermal models to account for thermal mass of concrete masonry, providing a more accurate thermal resistance of the buildings constructed of the material. The CHMA’s thermal mass software is location dependent, using local weather data. This software can account for thermal mass, instead of only steady-state thermal models currently used in the NECB. Figure 14 shows the inputs of the CMHA’s thermal mass software. Figure 15 illustrates the effective R-value after accounting for thermal mass for a concrete block backup wall with R-20 exterior insulation (101.6 mm [4 in.] XPS) and 90 mm (3.5 in.) brick veneer in New York City. The effective R-value is R-27.7. The steady-state thermal analysis methods required by NECB would estimate the effective R-value of the same wall (with embedded ties) at R-20.6.

Conclusion

The embodied carbon of concrete block can be reduced either passively through natural weathering carbonation, or by pre-carbonation using modern technology that can cure concrete block using CO2. EPDs, both nationally averaged and plant-specific, are now available for concrete block masonry products. Embodied carbon has also been reduced in concrete block manufacture by the substitution of GUL for the general use and Portland cement GU, which has translated to a 7.7 percent reduction in the GWP of concrete masonry products.

Recent collaboration with the University of Alberta has led to improved thermal bridging values for concrete block walls. These values were used to demonstrate that concrete block masonry can achieve net-zero energy requirements of 0.15W/m2 K for the opaque wall and 0.8W/m2 K for fenestration and doors, after thermal bridging in the opaque wall of the front elevation of an office building.

Determining the thermal mass effects of concrete block is already being accounted for in the U.S. code and is another way concrete masonry supports climate-friendly construction. Introduction of this into the NECB would be advantageous, not just for masonry, but for any material that exhibits thermal mass effects.

The masonry industry is committed to reducing its carbon footprint, from embodied carbon using innovative ways to reducing emissions during manufacturing, and in operational carbon by ensuring exceptional thermal performance in the envelope to reduce thermal energy use in buildings constructed with this resilient material.

Notes

1 Refer to classicrockfaceblock.com/news/the-history-behind-rock-face-block[5].

2 Visit www.oneclicklca.com/lca-glossary-for-construction-infra-manufacturing[6].

3 Learn more about EPDs at ccmpa.ca/resources-publications/environmental-product-declaration[7].

4 Visit Passive House Canada at www.passivehousecanada.com/downloads/Passivhaus_Primer.pdf[8].

5 Read the report, Issues, Impacts, and Mitigations of Carbon Dioxide Emissions in the Building Sector, at www.mdpi.com/2071-1050/12/18/7427[9].

5 See the ASTM standard, www.astm.org/stp164020210112.html[10].

6 Visit the online thermal catalogue at thermalenvelope.ca/catalogue[11].

7 Refer to the report at publications.gc.ca/collections/collection_2018/cnrc-nrc/NR24-24-2017-eng.pdf[12].

8 Learn more about energy efficiency at masonrycouncilontario.ca/energy-efficiency[13].

9 See ncma.org/software/matss[14].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/02/Opening-Figure.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/02/Figure-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/02/Figure-13.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/02/Figure-14.jpg

- classicrockfaceblock.com/news/the-history-behind-rock-face-block: https://classicrockfaceblock.com/news/the-history-behind-rock-face-block/

- www.oneclicklca.com/lca-glossary-for-construction-infra-manufacturing: http://www.oneclicklca.com/lca-glossary-for-construction-infra-manufacturing

- ccmpa.ca/resources-publications/environmental-product-declaration: https://ccmpa.ca/resources-publications/environmental-product-declaration

- www.passivehousecanada.com/downloads/Passivhaus_Primer.pdf: https://www.passivehousecanada.com/downloads/Passivhaus_Primer.pdf

- www.mdpi.com/2071-1050/12/18/7427: https://www.mdpi.com/2071-1050/12/18/7427

- www.astm.org/stp164020210112.html: https://www.astm.org/stp164020210112.html

- thermalenvelope.ca/catalogue: https://thermalenvelope.ca/catalogue

- publications.gc.ca/collections/collection_2018/cnrc-nrc/NR24-24-2017-eng.pdf: https://publications.gc.ca/collections/collection_2018/cnrc-nrc/NR24-24-2017-eng.pdf

- masonrycouncilontario.ca/energy-efficiency: https://masonrycouncilontario.ca/energy-efficiency

- ncma.org/software/matss: https://ncma.org/software/matss/

Source URL: https://www.constructionspecifier.com/harnessing-concrete-masonry-for-climate-friendly-buildings/

Mark Hagel holds a bachelor of science in actuarial science and applied mathematics, a bachelor of science in civil engineering, and a

Mark Hagel holds a bachelor of science in actuarial science and applied mathematics, a bachelor of science in civil engineering, and a  Mike Lafontaine is a key account manager with Oldcastle APG Canada West. He holds the following designations: CTR., SSG., SD. Lafontaine previously owned an advertising company with locations in Alberta and British Columbia. He can be reached via email at mike.lafontaine@oldcastle.com.

Mike Lafontaine is a key account manager with Oldcastle APG Canada West. He holds the following designations: CTR., SSG., SD. Lafontaine previously owned an advertising company with locations in Alberta and British Columbia. He can be reached via email at mike.lafontaine@oldcastle.com.