Improving on LEED with LEDs: Energy conservation upgrades at a Maryland office building

by Sarah Said | October 12, 2018 3:14 pm

by John Boland

[1]

[1]The quest for energy efficiency should not stop after a building is certified under the Leadership in Energy and Environmental Design (LEED) program. Technologies capable of reducing energy costs continue to evolve and are in a state of flux. Therefore, there is always potential for improvement upon the technology used in a LEED-certified building. Perhaps no area of building technology has improved so rapidly as the lighting industry.

Technological advances in features such as occupancy sensors, lamps, light-emitting diodes (LEDs), daylight sensors, and dimmers have evolved to provide greater energy efficiency and control than ever before, all while becoming increasingly cost-effective for building owners. One engineering firm headquartered in a LEED-certified building in Maryland decided to demonstrate its commitment to sustainability with a complete change-out of its relatively new light fixtures for a more energy efficient technology.

The details

RMF Engineering became the tenant of a new LEED-rated office building in early 2009. The four-story, 9735-m2 (104,791-sf) structure is located on the research and technology park campus of the University of Maryland Baltimore County (UMBC) in Catonsville, Maryland. RMF occupies the entire third floor and shares the remaining space in the building with 12 tenants. The building has a generous number of windows on all four sides, providing significant amounts of natural daylight for occupants to enjoy.

The LEED Silver-rated building was originally equipped with 0.61-m (2-ft) and 1.2-m (4-ft) 120/277-volt ceiling fixtures, each with two, 54-watt fluorescent lamps. Each fixture utilized a perforated basket louver designed for 90 percent uplight and 10 percent downlight, and was constructed of half-round, flat, black-painted stamped steel. When fully energized, each 1.2-m fixture, using a standard ballast, would draw an average of 108 watts of electricity. The majority of the office workspaces include desks supporting computers with multiple flat-screen monitors employing a variety of computer-aided design (CAD) software packages for the design of complex buildings and utility networks.

[2]

[2]Over the course of several years, it became commonplace throughout the workspaces for employees to physically remove one or both of the lamps in the overhead light fixtures to create a more comfortable environment and gain more visual contrast on the computer terminal displays. The workstations are operated daily for precise CAD work on complicated diagrams and plans. In this environment, ceiling lights can create a challenge visually and can increase employee fatigue. Making the manual light adjustments aided productivity across the headquarters, especially during extended work hours in the early morning and late evening.

The measurable light levels at working surfaces typically ranged from 377 to 700 lux (35 to 65 footcandles [FC]) and were considered excessive by some occupants. The entire third floor utilized 344 lay in fluorescent fixtures including 0.61 x

1.2 m (2 x 4 ft) and 0.61 x 0.61 m sizes suspended in ceiling grids spaced 1.2 m (4 ft) apart, approximately 2.5 m (8.10 ft) above the finished floor. Zone occupancy sensors were also in place, controlling approximately 20 fixtures at a time.

It was observed employees needed more individual control of overhead light to create optimal working conditions. RMF’s property manager at Corporate Office Properties Trust (COPT) consulted with a local light supplier to examine several options for replacing fixtures with new ones offering higher efficiency and more precise control for the office manager and employees. A LED fixture was, ultimately, selected.

The fixture is a low-profile, integrated LED with an optional sensor for detecting occupancy, vacancy, and daylight harvesting. The operating life expectancy of the selected unit is 100,000 hours and it provides up to 124 lumens per watt, making it premium-rated by Design Light Consortium (DLC). Other features included accessibility to the LED board from below the ceiling. The wireless programmable sensor allowing remote control for the office manager without hard-wired switches made the fixture especially appealing to COPT.

[3]

[3]Preparation and planning

The retrofit was accomplished with little disruption to the workplace. Baltimore-based Freestate Electric served as the electrical contractor for the lighting project and developed a plan to replace fixtures one for one during RMF’s normally occupied work hours without disrupting the firm’s business activities. The electricians removed the existing lamps from each fixture and then took out the luminaire body after disconnecting branch circuit and control wiring. Each new light could be easily installed by one electrician without a helper. Each new fixture was then placed into the ceiling support grid and reconnected to the original branch circuit and control wiring.

A team of eight electricians worked through December, 2017, and replaced an average of 60 fixtures per day. On completion of fixture replacements, each unit was checked, tested, and placed into operation. In rare cases, defective fixtures were replaced as needed.

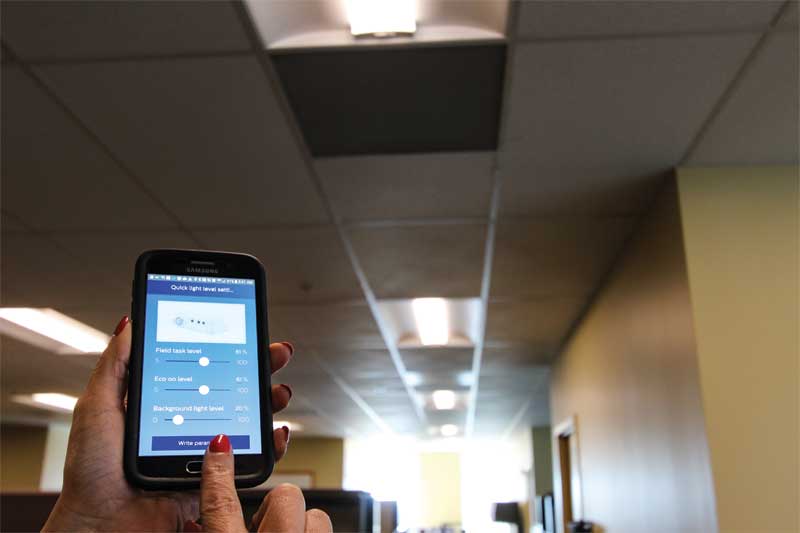

At this point, the original occupancy sensors were redundant so they were disabled. Next, the new controls were adjusted for each occupant’s preference for specific levels of light. Settings were modified by a field service application available through a smartphone, which provided the ability for unlimited subsequent changes. Tuning of light levels throughout the office is now easily performed by the office manager at the touch of a button.

Results

When the lighting settings within the office spaces had been fully adjusted, the preferred light levels were reduced by 377 to 538 lux (35 to 50 FC) and in many cases, this represents approximately 35 percent of the rated output. Compared to the original T-5 fluorescent lamp-type fixtures which had drawn as much as 108 watts each, the new fixtures drew only 12.5 watts. In many cases, the employees preferred a reduced light level in the office spaces, resulting in as little as 15 percent of the previous electric demand.

The new lights and controls have been in operation since the beginning of 2018 and produce customized light levels to suit more than 120 employees. The remaining three floors and common spaces throughout the building have also been converted to the lighting technology now utilized in the RMF offices. In all, 1045 fixtures were replaced throughout the building. The reduction in electricity demand is projected to translate to a 50 percent reduction in energy costs over the course of the year.

[4]

[4]While the energy savings will amortize the cost of the improvements for COPT, a rebate program known as “BGE Smart Energy Savers” offered through the Baltimore Gas and Electric Utility also provided a financial incentive of $130 for every replacement unit to assist in the purchase and installation. BGE provides instant lighting discounts to purchase LEDs for installation in commercial and residential spaces, much like other providers throughout the region. This accelerated the payback period for the building owner. The rebate for the entire building lighting project is valued at $150,000. It is critically important to plan in advance and submit the work for approval before beginning any changes as the incentives are meant for upgrading existing systems and will not be provided for an already completed installation.

Conclusion

According to the U.S. Green Building Council (USGBC), since its formation in 1993, and the unveiling of its initial guidelines in 2000, LEED certification has been granted to nearly 100,000 facilities and more than 185,806-m2 (2-million sf) of new space is certified every day. However, LEED certification is not merely a one-time accomplishment. The ultimate goal of the USGBC is to have a net-zero impact from the construction and operation of buildings. In fact, LEED rating for operations and maintenance requires continued action to maintain the certification.

Every three to four years, the guidelines for LEED certification are updated. However, the energy reduction target is increased more frequently. Today, LEED v4 is the standard designers use, and it places considerably more emphasis on energy conservation than earlier versions.

This lighting project was an opportunity to demonstrate even LEED-certified buildings less than 10 years old can be good candidates for energy conservation upgrades. The LEED program has made for more energy efficient buildings, but energy conservation measures should always be considered as buildings age and technologies improve.

John Boland is an electrical designer at RMF Engineering. His expertise is lighting and electrical power supply and distribution in both new and renovated facilities such as offices, hospitals, and laboratories. He can be reached at john.boland@rmf.com[5].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/10/IMG_2248.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/10/IMG_6438.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/10/IMG_7470.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/10/IMG_7490.jpg

- john.boland@rmf.com: mailto:john.boland@rmf.com

Source URL: https://www.constructionspecifier.com/improving-on-leed-with-leds-energy-conservation-upgrades-at-a-maryland-office-building/