Proactive HVAC maintenance: Balancing costs with sustainability

by tanya_martins | May 10, 2025 10:20 am

By Andrew Soulier and Bryant Kuvako

[1]

[1]As the HVAC industry approaches the first half of 2025, it finds itself at a pivotal crossroads between rising equipment costs and a greater demand for sustainability. These challenges create substantial opportunities for innovation and leadership across the industry. This article examines how a proactive approach to HVAC maintenance can help owners and operators reduce costs in the short term and be better prepared for future upgrades.

[2]

[2]

With equipment prices anticipated to rise further, extending the lifespan of existing systems will be crucial for managing costs. Additionally, the evolving landscape of building performance and decarbonization policies requires industry professionals to remain adaptable and responsive to new regulations. By balancing both financial and environmental responsibility, facility managers can help steer their organizations to be more sustainable and cost-effective from the inside out.

Rising equipment costs and the need for preventative maintenance

Since 2020, HVAC equipment prices have surged, driven by rising raw material costs, supply chain disruptions, regulatory changes and labor shortages.1 Some equipment costs have nearly doubled, with an average increase of around 40 percent. Contributing factors include the phase-out of R-410A refrigerants and the introduction of low-GWP alternatives such as R-454B, which have driven up manufacturing costs. Major manufacturers, such as Lennox and Carrier, project significant price increases even into the future as they adapt to modern regulatory changes and introduce new product lines.

With rising costs in the HVAC industry—exacerbated by impending refrigerant changes and the likelihood of further price increases—the trend toward repairing existing systems rather than replacing them is gaining momentum. Repairing and maintaining existing systems helps control expenses by extending equipment lifespan, reducing the frequency of costly emergency repairs, and improving energy efficiency. Without routine upkeep, aging HVAC systems consume more energy and are prone to sudden failures, leading to unplanned financial burdens.

To mitigate these expenses, HVAC professionals must shift from reactive to proactive maintenance strategies. Regular maintenance is no longer just a best practice—it is a financial necessity. Proactive system management, including routine inspections, cleaning and timely repairs, ensures that equipment operates efficiently, reducing downtime and decreasing energy consumption by 10 to 20 percent.2

The financial impact of deferring HVAC maintenance can be substantial. Reactive approaches to system issues often lead to emergency repairs that carry premium costs, with the risk of more severe, long-term damage that may necessitate complete system replacements. In contrast, a comprehensive preventive maintenance plan identifies and addresses potential issues before they escalate, fostering predictable budgets and reducing the likelihood of unplanned financial burdens. Property owners who prioritize regular check-ups and servicing reduce operational disruptions and enhance tenant comfort, protect property values and stabilize operating expenses. Moreover, preventive HVAC maintenance is integral to energy efficiency—a critical factor in cost management and sustainability—aligning with both economic and sustainability goals.

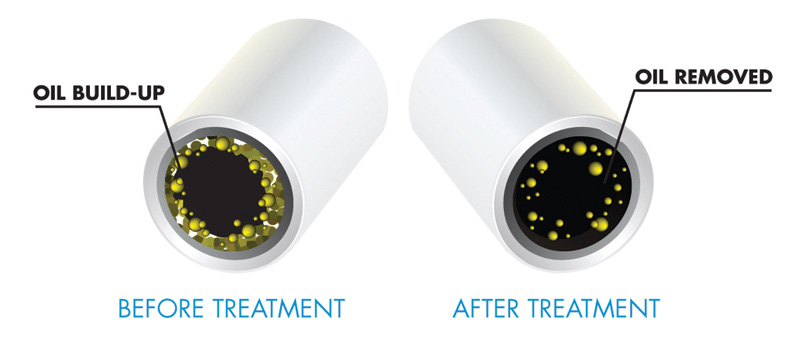

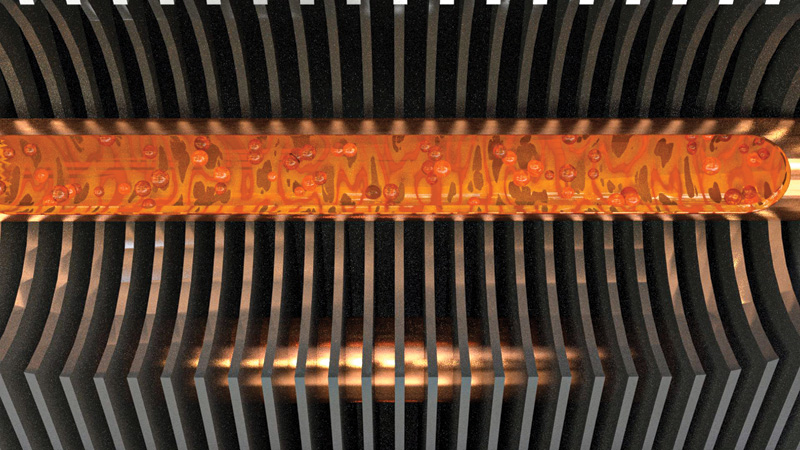

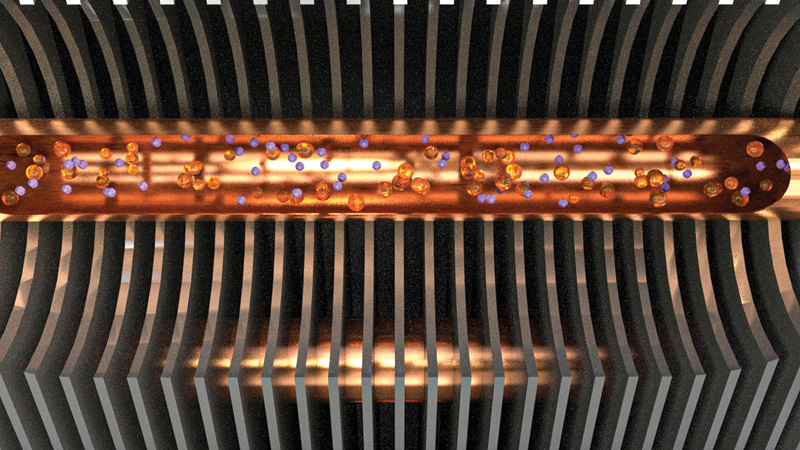

Enhancing system efficiency with advanced lubricant

Traditional maintenance for commercial HVAC systems typically emphasizes mechanical components, focusing on reducing breakdowns and improving energy efficiency. However, a critical yet often overlooked aspect of system performance is the degradation of refrigerant oil. Over time, the oil breaks down and accumulates on the interior surfaces of heat exchanger coils, creating a thermal insulating barrier. Instead of returning to the oil sump in the compressor where it belongs, the oil adheres to the tubes, impairing heat transfer. As a result, buildup reduces system efficiency and leads to increased energy consumption, negatively impacting overall performance.

Many industry professionals are now turning to advanced lubricants to address this issue. These chemical compounds enhance heat transfer and reduce wear and tear on HVAC components. Independent studies have validated that modern oil lubricants deliver significant benefits, such as quick payback periods, up to

20 percent recurring savings on operational costs and long-term system performance improvements. By adopting these advanced solutions, facility managers can not only boost efficiency but also extend the lifespan of both new and aging HVAC systems, ensuring better financial returns.

[3]

[3]Adapting to benchmarking, energy, and sustainability policies

The HVAC industry is also being shaped by city, state, and national policies to improve building energy performance and/or achieve significant carbon reduction targets. As these policies push businesses toward cleaner and more efficient technologies, HVAC systems—which account for 67 percent of the total emissions in buildings3—are under increased scrutiny. As aging equipment fails, replacing systems with identical models offers little progress toward sustainability goals. Instead, facility managers must identify opportunities to upgrade to more energy-efficient solutions while staying within budget constraints.

Getting ahead of the curve does not have to be financially overwhelming. Facility managers can strategically manage this shift by reducing short-term costs, implementing upgrades gradually, optimizing current systems and leveraging available incentives to alleviate financial pressure. By pairing short-term wins with pieces of a long-range plan, FMs can help soften costs and build momentum for future upgrades.

[4]

[4]

[5]

[5]The strategic importance of sustainability

Sustainability in HVAC operations has become a priority for many organizations, driven by the significant energy consumption of HVAC systems and the environmental impact of refrigerants used in most equipment, which are closely monitored under greenhouse gasses (GHG) reporting protocols.

A recent report by the International Energy Agency (IEA) states HVAC systems contribute to a staggering 15 percent of global CO2 emissions.4 As a result, emerging policies aimed at reducing carbon emissions will either directly or indirectly lead to stricter HVAC energy efficiency standards and incentivize the adoption of greener technologies.

For facility managers, adopting sustainability as a best practice is not just a compliance measure but a strategic move toward long-term success. This starts with eliminating energy waste and improving maintenance practices to reduce operating expenses in the short term but evolves into programming better efficiency into operations and procurement over the long term. Businesses can significantly reduce their environmental impact and operating expenses by implementing a series of no-cost and low-cost measures and use those savings to help justify further investment in sustainable performance and/or regulatory compliance.

Sustainable strategies should produce clear benefits in the following areas:

- Enhancing compliance and competitive edge—Ensuring adherence to evolving regulations while providing a competitive advantage.

- Improving cost efficiency and long-term savings—Reducing energy bills and maintenance costs through energy-efficient systems.

- Optimizing performance and reliability—Reducing operational costs and maintenance needs with modern, sustainable HVAC systems.

- Reducing environmental impact—Lowering GHG emissions with energy-efficient technologies.

- Enhancing indoor environment and productivity—Boosting productivity and wellbeing through improved indoor air quality and comfort.

- Future-proofing—Preparing for future regulations and market demands with early adoption of advanced technologies.

- Implementing proactive maintenance strategies—Extending the life of existing equipment, improving system efficiency and preventing costly emergency repairs through regular inspections, cleaning and timely repairs.

[6]

[6]Leveraging AI for HVAC optimization

AI and machine learning are revolutionizing HVAC systems by optimizing predictive maintenance, control strategies, diagnostics, and load balancing. These advancements reduce energy consumption, operational costs, and emissions. AI can optimize HVAC systems through:

- Predictive maintenance—Preventing costly repairs by forecasting failures and optimizing performance. For example, AI-driven sensors can analyze vibration patterns in compressors to predict failures, reducing unplanned downtime and extending equipment lifespan.4

- Optimized control strategies—Adjusting settings in real-time based on occupancy and weather conditions.

- Fault detection and diagnostics—Reducing time and resources necessary to identify a fault.

- Energy use optimization—Minimizing energy consumption while maintaining comfort.

- Dynamic load balancing—Efficiently distributing heating and cooling loads across multiple units more efficiently. A real-world example is AI-driven HVAC systems in large hospitals that adjust air handling units to balance demand in different wings, preventing overuse of certain equipment while optimizing both comfort and energy efficiency.

Equipped with these insights, while emerging AI and property technology offer promising opportunities, the foundational principles of efficiency and maintenance remain crucial. The most effective facility managers understand the importance of balancing both—leveraging cutting-edge technologies while maintaining a strong focus on traditional maintenance practices. It is not a matter of choosing one over the other, but rather integrating both strategies to ensure optimal performance and long-term sustainability.

Leading the way beyond 2025

As 2025 progresses, the HVAC industry faces both challenges and opportunities. Industry leaders can effectively navigate these pressures by prioritizing proactive maintenance and sustainability. Maintaining and optimizing existing equipment remains a critical strategy for controlling costs, improving efficiency, and extending system lifespan. At the same time, embracing new technologies—such as advanced lubricants and AI-driven monitoring—can enhance performance, reduce energy consumption, and support sustainability goals.

These innovations and a strong maintenance strategy provide significant operational savings and ensure new and aging systems operate at peak efficiency. Looking ahead, the HVAC industry has the potential to lead in sustainability, setting new standards for environmental responsibility and innovation. Facility managers who take a proactive approach—integrating preventive maintenance and emerging technologies—will be well-positioned to excel in the competitive and regulation-driven landscape 2025 and beyond.

Notes

1 See[7].

2 Refer.[8]

3For more information, visit[9].

4 Read more[10].

Authors

Andrew Soulier leads sustainability efforts at ECM Technologies, focusing on energy efficiency, market development and green practices. He oversees sustainability reporting, regulatory compliance and client engagement, helping ECMT become a global leader in HVAC sustainability. Soulier is also the founder of Net Positive Advisors and serves in leadership roles with the U.S. Green Building Council (USGBC). He holds a bachelor of science in mechanical engineering from ASU, is a LEED-accredited professional, and a certified energy manager.

Bryant Kuvakos has been a driving force behind Tolin’s success in Arizona since joining the company in September 2005 as the Phoenix branch general manager. In January 2008, he advanced to vice president of Tolin’s Arizona operations. A graduate of the University of Illinois at Chicago, where he earned a bachelor of science in business administration, Kuvakos has played a pivotal role in growing Tolin’s presence in Arizona. His efforts include developing a strong employee and customer base and spearheading the opening and expansion of the Tucson branch.

Key Takeaways

As HVAC costs rise and sustainability demands grow, proactive maintenance is key to reducing expenses and extending system lifespan. Innovations such as AI and advanced lubricants enhance efficiency, while regulatory shifts require adaptability. Integrating smart maintenance and sustainability strategies ensures long-term success in a competitive, evolving industry.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/06/Proactive-Strategies-for-HVAC-Sustainability-and-Cost-Management.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/06/Installing-advanced-lubricant-in-aging-HVAC-system.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/06/oil-fouling-before-and-after.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/06/Before-Oil-Additivies.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/06/After-Oil-Additives.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2025/06/Testing-HVAC-equipment-with-thermal-gun_.jpg

- See: http://www.achrnews.com/articles/154696-hvac-equipment-prices-expected-to-keep-rising

- Refer.: http://betterbuildingssolutioncenter.energy.gov/solutions-at-a-glance/preventative-maintenance-commercial-hvac-equipment

- visit: http://www.iea.org/energy-system/buildings

- Read more: http://www.mdpi.com/1424-8220/25/4/1006

Source URL: https://www.constructionspecifier.com/proactive-hvac-maintenance-balancing-costs-with-sustainability/