Unlocking BHMA’s updated standards

by arslan_ahmed | September 22, 2023 8:00 pm

[1]

[1]By Michael Tierney and Karen Bishop

There are multitudes of standards for builders’ hardware that, not only provide precise definitions for hardware terminology, but also establish and describe rigorous testing methods to evaluate their performance.

The American National Standards Institute (ANSI) and the Builders Hardware Manufacturers Association (BHMA) set forth standards that are used by specifiers, architects, and other key players in the construction world. These standards apply to a diverse array of hardware and are updated every five years as required by ANSI. By adhering to these standards and requirements within, construction projects can confidently specify hardware products which meet the necessary criteria of both quality and functionality.

In their usual process, BHMA members participated in a series of subcommittee meetings throughout 2021 and 2022, followed by steps to final approval set by ANSI, and published the updated standards in late 2022. The locks and applications in these updated standards are primarily used for heavy duty purposes in commercial buildings such as schools, office buildings, hospitals, and more. This article provides a brief overview of the changes made to the four standards below and more:

- ANSI/BHMA A156.2, Bored and Preassembled Locks and Latches

- ANSI/BHMA A156.12, Interconnected Locks

- ANSI/BHMA A156.13, Mortise Locks and Latches

- ANSI/BHMA A156.24, Delayed Egress Locking Systems

ANSI/BHMA A156.2, Bored and Preassembled Locks and Latches

A156.2-2022 establishes requirements for bored and preassembled locks and latches, and includes cycle, strength, operational, and material evaluation tests, and dimensional criteria. Although these standards are 40- to 50-years-old and considered “mature,” BHMA opens and revises them for many reasons, including keeping up with technology advances, changes to building codes, marketplace demands, and the implementation of new innovations.

[2]

[2]One of the revisions to this standard includes finish requirements removed and consolidated in A156.18-2020, which provides a comprehensive table with finish code numbers, descriptions, and equivalent finishes. Hardware products have mechanical requirements, but they must also have a certain aesthetic appeal, which is why various finish tests are performed. For example, a finish test can include salt spray or humidity explorations, and the standards would include instructions on how to properly execute these tests within the appropriate amount of time, etc. However, with this revision, which was applied to the four standards, the finish requirements can now be found in A156.18.

Another revision to this standard was updated references to ASTM F476, Standard Test Methods for Security of Swinging Door Assemblies. BHMA references many test methods in ASTM F476 and when a test method changes, related updates need to be made to the affected standards. In addition to this update, definitions in the standard were synched with ANSI/BHMA A156.13. There is a constant effort to ensure BHMA provides standard industry definitions for products. If one standard includes a definition that may differ, even the slightest, from the same term in another standard, then revisions are made to keep them synonymous. Other revisions made to this standard include editorial corrections such as a re-arrangement of paragraph four and added paragraph numbers in Section 10 and 11.

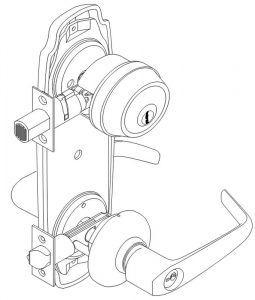

ANSI/BHMA A156.12, Interconnected Locks

These products are commonly used to meet building and fire code requirements, such as adhering to a single releasing motion to unlatch a door for egress. Interconnected locks withdraw the deadbolt at the same time as a person unlatches a door; these locks exist so anyone who needs to exit a building can do so, especially during unforeseen situations. These are important for commercial buildings to avoid any confusion or unfamiliarity with door functions to a respective building.

In a residential perspective, interconnected locks are primarily used for multi-family buildings, where the risk of fires or other emergency situations may be higher. Commercial locks, with few exceptions, are designed so there is one motion to exit a building even when the door is locked from the outside. The accompanying standard for this is A156.4, Single Motion to Egress, which describes the requirements for door hardware to comply with such codes. This

is mandated in case of panic situations, emergencies, and to improve accessibility.

[3]

[3]A156.12 establishes the requirements for interconnected locks, including dimensional criteria and operational, strength, security, and cycle tests. These different types of tests are crucial as they relate to the performance and quality of the products. For example, in A156.12, the Dead Bolt Sawing Test states, “dead bolts shall resist sawing through for the period specified when fed into a band saw with a sustained 5 lbf [22 N],” adding specifications on how the force should be applied, the sizing of the blade, and other important test details. One revision made to this section is the inclusion of using a 12.7 mm (0.5 in.) blade in addition to the 6.35 mm (0.25 in.) blade already described in the standard. BHMA opens standards for revision to make sure test methods are clarified for everyone involved, and to update performance testing requirements

when necessary.

Apart from consolidating finish requirements to A156.18, Materials

and Finishes, other revisions include suggested edits to the appendix, clarifications made to section 8.5, and creating separate paragraphs of the requirements in section 10.4. Further, any definitions of terms not directly applicable to the standard were deleted.

ANSI/BHMA A156.13, Mortise Locks and Latches

BHMA standards begin with a scope section followed by a set of definitions in Section 2. A156.13 defines mortise locks as “a lock or latch fitting into a mortised cavity prepared in the edge of a door where the bolts are operated by knobs, levers, turns, thumb pieces, paddles or cylinders that engage with the mortise lock through holes prepared in the faces of the door.” These kinds of locks are often selected for their durability and security as they are considered the most durable, offer additional security, and are meant for heavier duty applications. Standards provide general requirements related to building codes and, depending on the standard, offer descriptions on test methods and detailed test requirements.

Revisions made to this standard include clarified test cylinder requirements to 3.1 and 6.5, “Specified Impact Test location,” updated reference documents, and re-formatted “Bolt Compressive Load Test” section—which applies only to products with a dead-locking latch bolt or a dead bolt. A reference to A156.41, Door Hardware Single Motion To Egress, was also added to emphasize the importance of this standard and its requirements. Lastly and customarily, the final section of a standard includes the function and/or type numbers.

When BHMA revises a standard, new function and type numbers are added when needed, to accommodate innovations. Another revision made to this standard were requirements to cover narrow stile mortise locks, which permit installation within narrow-width aluminum door stiles, and its design allows for installation flexibility for all other types of doors. Narrow stile mortise locks, also known as narrow backset mortise locks, were previously in A156.36, Auxiliary Locks, but it was decided that A156.13 was a more appropriate location for reference and specification. These locks would have lower values than standard mortise locks and several tests would be in addition to existing auxiliary types, therefore new function numbers and tests have been added to A156.13.

[4]

[4]Function numbers are crucial as they are used by specifiers to pick the application needed. The function numbers in this standard cover residential to commercial settings, including passage/closet latches, hotel guest locks, and front door lock functions. There are also functions for classrooms which involve certain kinds of locking arrangement due to the unfortunate increase of school shootings. Teachers and school boards have insisted on incorporating locks that allow staff and students to lock classrooms from the inside as opposed to the outside like they typically do. Classroom security continues to grow as a concern in the building code and construction field.

ANSI/BHMA A156.24: Delayed Egress Locking Systems

A156.24 covers products used in connection with conventional exit devices or locks causing the doors to remain locked after releasing actuation for a predetermined length of time. This refers to doors that have a short delay in opening to prevent individuals, who may not be allowed to leave, from exiting the building. The delayed egress meets building code requirements, prevalent where patients and residents should not wander off. This includes facilities such as memory care wards, psychiatric and mental health units, and senior assisted living. These are also common in airports doors leading out to the tarmac, as well

as big retail stores, for anti-theft purposes and additional security.

There were important tweaks made to this standard, including a revision to the test door hinge description in 4.2 under “test methods,” stating, “Doors shall be hung on Grade 1 heavy-duty anti-friction bearing hinges or pivots.” In addition, reference standards were updated, style formatting was edited to match standard documents, and details covered in building codes were transferred out of the standard. A156.24 includes performance criteria for functional, cycle, operational, fail-safe, and overload requirements.

How do these standards affect the industry?

A good portion of these standards deals with detailed instructions on how to test and evaluate the performance of the hardware, to be followed by the test labs and manufacturers. This should be helpful to specifiers as the testing results offer a grading rank from 1 to 3. Grade 1 being the highest and suitable for the most rigorous applications, while grades 2 and 3 might be more economical choices for other lower demand installations. For example, the cycle tests are done under laboratory conditions, often with extra loads, so the exact quantities are not directly transferable to their life in actual installations, and in fact could be expected to exceed them. The standards also set industry definitions and terminology as well as detailed descriptions of the various “functions” or “types” to select for the applications (i.e. storeroom or entrance functions).

Although these changes do not directly affect architects and specifiers, BHMA standards allow for a common language between architects, specifiers, and builders to communicate about the different types and required performance levels of architectural hardware products.

BHMA is currently working on standards relating to energy consumption of electrified hardware, acoustic properties of hardware for noise sensitive applications such as hospitals, and the development of test methods for architectural hardware resistance to harsh environments.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/09/Delayed-Egress-Pair.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/09/bigstock-Wooden-Hotel-Door-With-The-Sig-459322705.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/09/bigstock-Close-Up-Key-On-The-Door-With-476944629.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/09/156.12-Interconnected-Locks.jpg

Source URL: https://www.constructionspecifier.com/shedding-light-on-builders-hardware-manufacturers-association-updated-standards/

For more than 20 years, Michael Tierney has served as the product standards director for Builders Hardware Manufacturers Association (BMHA), where he coordinated the development and revision of the BHMA performance standards for building hardware products. Tierney came to BHMA following a 20-year career in manufacturing management at United Technologies, Honeywell, Black and Decker, and Yale Security. He is a principal member on technical committees for the National Fire Protection Association (NFPA); the A117.1, Committee

For more than 20 years, Michael Tierney has served as the product standards director for Builders Hardware Manufacturers Association (BMHA), where he coordinated the development and revision of the BHMA performance standards for building hardware products. Tierney came to BHMA following a 20-year career in manufacturing management at United Technologies, Honeywell, Black and Decker, and Yale Security. He is a principal member on technical committees for the National Fire Protection Association (NFPA); the A117.1, Committee Karen Bishop has extensive technical and managerial experience in the commercial openings industry. Before joining BHMA, she served as a senior engineer for new product development, certification, and testing at the Allegion Hollow Metal Group. Bishop has held leadership roles at several associations, including Steel Door Institute (SDI) and National Association of Architectural Metal Manufacturers (NAAMM), among others.

Karen Bishop has extensive technical and managerial experience in the commercial openings industry. Before joining BHMA, she served as a senior engineer for new product development, certification, and testing at the Allegion Hollow Metal Group. Bishop has held leadership roles at several associations, including Steel Door Institute (SDI) and National Association of Architectural Metal Manufacturers (NAAMM), among others.