Testing Fluid-applied Air and Water Barriers

by Catherine Howlett | December 1, 2012 12:00 pm

[1]

[1]Fluid-applied air and water barrier products have rapidly gained market share in many areas of the country, but they are still relatively new to the industry. It is perhaps unsurprising then that various failures of these products have been seen during their installation.

[2]

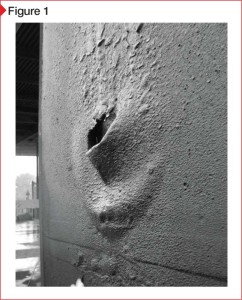

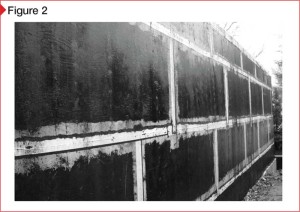

[2]The opportunity to observe these conditions is relatively narrow and usually occurs in the first few weeks of application before the exterior cladding is installed over the barrier. The most significant of these issues include cured membranes developing large water-filled blisters (Figure 1) or sliding off the wall (Figure 2). These failures occurred after the membrane had been installed for at least two weeks and immediately following rain. Their occurrence indicates excessive water absorption leading to poor adhesion, or reversion of the membrane to a fluid-like state.

Other shortcomings observed in the field include tearing of the membrane along the edge of self-adhered flashing, and alligator cracking of its surface. The first is symptomatic of poor elongation properties of the membrane, while the second is likely caused by excessive ultraviolet (UV) exposure.

Currently, the industry has few standards addressing the durability of these products, particularly when exposed to moisture over the long term. Many of these assemblies serve as the water-resistive barrier (WRB), as well as the air barrier for the wall. The Air Barrier Association of America (ABAA) evaluates fluid-applied systems by testing air permeance, water resistance, fastener sealability, adhesion to substrates (i.e. pull adhesion), and crack bridging.

The water resistance testing—per American Association of Textile Chemists and Colorists (AATCC) 127-03, Water Resistance: Hydrostatic Pressure Test—gauges the cured membrane against hydrostatic pressure for five hours. In reality, many membranes will be exposed to moisture for much longer than this period, particularly when used in the wet zone of the wall assembly. While the ABAA evaluation addresses initial performance, it does not deal with long-term durability issues. Even so, widespread project failures are observed even with products that have been evaluated, and approved, by ABAA. Although ASTM is developing a standard for fluid-applied air barriers, it does not currently address durability issues for these products.

[3]

[3]Given the relatively short track record of these products and the failures observed with some, it seemed prudent to develop an in-house program of laboratory testing to better assess their prospects for long-term performance. For practical reasons, the testing program was limited to products from four manufacturers that were early leaders in the fluid-applied air barrier market.

Both vapor-permeable and vapor-impermeable products from each manufacturer (including two vapor-permeable ones from the same company) were tested for a total of nine. These materials included membranes that exhibited those aforementioned problems in an attempt to replicate the failures in the laboratory and confirm suspected mechanisms. The ultimate goal was to have a basis for deciding their prospects for long-term performance in lieu of a historical track record. This is particularly important since many building owners are interested in using these products; furthermore, many contractors are requesting these materials as alternates to more time-proven products such as self-adhered membranes.

Lab testing of fluid-applied air barriers

To achieve the set goals, testing focused on three important performance properties: pull adhesion, flexibility (i.e. elongation), and water absorption.

Pull adhesion

For a membrane to successfully perform as an air barrier, it must exhibit adequate adhesion to the wall substrate. The membranes were tested for adhesion to several common materials.

Flexibility

The membrane must span joints in sheathing boards, and joints between dissimilar materials, such as at flashings. These joints experience minor movements through the life of the building. Since the membrane must provide a continuous barrier, and not split or tear under these movements, its flexibility was evaluated by elongation testing.

[4]

[4]Water absorption

From previous testing of roofing and waterproofing membranes, water absorption has proven to be a good indicator of long-term membrane durability. Currently, no industry standards address water absorption of fluid applied membranes; therefore, traditional water absorption testing of waterproofing and roofing membranes is a starting point. Industry experience has shown reliable waterproofing membranes have low water absorption, ranging from less than a four percent increase by weight to an upper bound of 10 percent.

While the air barrier will be exposed to far less water than will a roofing or plaza waterproofing membrane, cladding systems are almost never watertight. This means the air barrier, which typically also acts as the WRB, is exposed to some water. Additionally, when insulation is used in the cavity wall, water can be held against the membrane for prolonged periods, trapped between the air barrier and the insulation. Often, water entering cavity walls does so at the same locations during each storm; while the entire wall membrane might not be wetted, other areas will be, repeatedly.

Summary of conditioning

To help assess the prospects for long-term product performance, samples were conditioned to reflect various environmental factors, and the pull-adhesion, elongation, and water-absorption tests were repeated. Conditioning of the samples included exposing them to UV light, freezing temperatures, accelerated aging, and water exposure. Only one conditioning element was applied to an individual sample, and not the aggregate of all the conditioning.

UV exposure

Using a UV fluorescent light apparatus, the samples were exposed to UV light for 14 days—22 hours of UV light followed by two hours of condensation daily.

No direct correlation can be made between hours in the UV machine and days exposed on a job site. Of all conditioning procedures, UV-exposed samples exhibited the greatest change in physical appearance.

All tested fluid-applied air barrier products, except one, are not marketed as ‘UV-stable’ and not intended to be exposed (permanently) to UV light. Still, all products will be exposed to UV for some amount of time, depending on the phasing of construction projects.

During testing, two of the membranes changed color after exposure. Three of the membranes, including the one marketed as ‘UV-stable,’ exhibited cracking and crazing of the exposed surface.

[5]

[5]Freezing temperatures

Before testing, the samples were exposed to –6.7 C (20 F) temperatures for 48 hours, followed by 24 hours minimum at room temperature.

Accelerated aging

The samples were oven-aged for 28 days at a temperature of 70 C (158 F), followed by 24 hours minimum at room temperature prior to testing.

Water exposure

For elongation testing, samples were submerged in distilled water for 24 hours. For adhesion testing, edges of the substrates were taped off to prevent water absorption by the substrate, and the membrane covered with wet burlap and polyethylene for 24 hours. All samples dried for at least 24 hours before testing.

Testing procedures

Testing of each respective property was conducted in general conformance with ASTM standards:

Adhesion to substrate

Using ASTM D4541, Standard Test Method for Pull-off Strength of Coatings Using Portable Adhesion Testers, adhesion of the fluid-applied air barriers was tested to six common construction materials, all of which are listed as acceptable substrates for the nine materials tested. As shown in Figure 3, substrates tested were:

- plywood;

- oriented strandboard (OSB);

- fiberglass mat gypsum sheathing;

- concrete masonry units (CMUs);

- gypsum wallboard; and

- self-adhered membrane flashing (product as recommended by each manufacturer).

Samples with the following conditioning were tested:

- unconditioned (control);

- freezer exposure;

- accelerated aging; and

- water exposure.

The samples could not be exposed to UV due to limitations of the machine on the size of the samples.

Elongation

A universal test machine was used to apply a tensile force to the ‘dog-bone-shaped’ samples, as per ASTM D412, Standard Test Method for Vulcanized Rubber and Thermoplastic Elastomers–Tension (Figure 4). Samples with the following conditioning were tested:

- unconditioned (control);

- freezer exposure;

- UV exposure;

- accelerated aging; and

- water exposure.

[6]

[6]Water absorption

Using ASTM D471, Standard Test Method for Rubber Property–Effect of Liquids, Procedure 10, samples were submerged in distilled water for 24 hours (Figure 5) and their increase in mass was measured. Samples with the following conditioning were tested:

- unconditioned (control);

- freezer exposure; and

- UV exposure.

Summary of test results

This section summarizes the results of the testing.

Adhesion to substrate (pull adhesion)

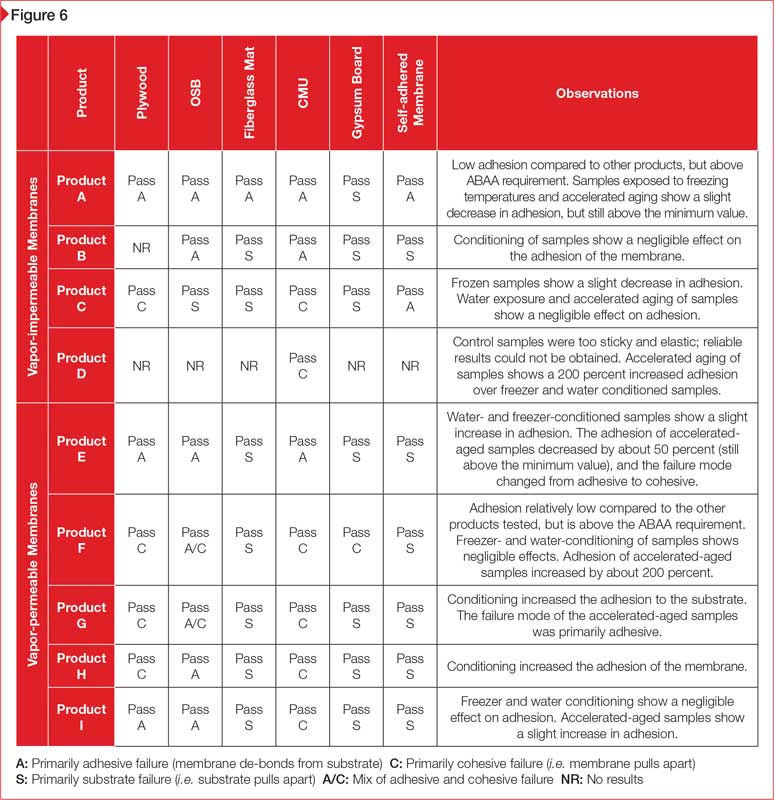

ABAA has set a minimum pull adhesion of 110 kPa (15.95 psi) in its evaluation, which is also used for this testing. The failure mode—cohesive, adhesive, or failure of substrate—is recorded for each sample. The membrane passes when the average stress at failure is greater than this value and fails when the average is less than or equal to it. As Figure 6 shows, all samples exhibited adequate adhesion to all substrates under all conditions.

Elongation testing

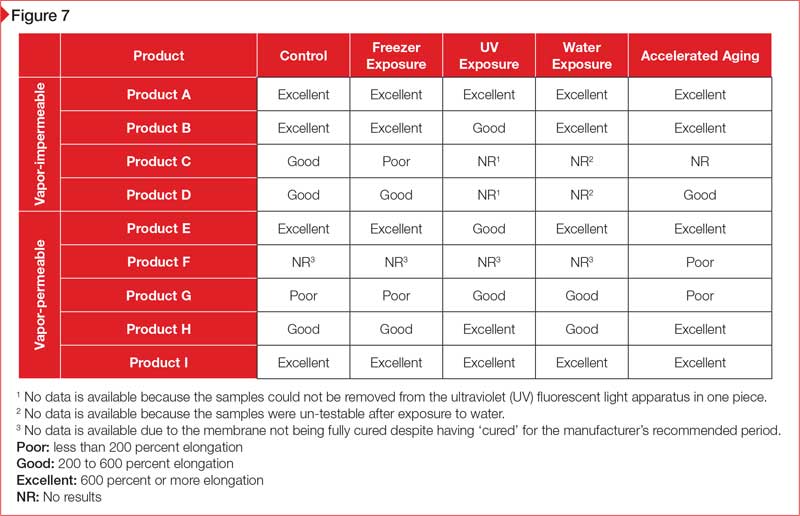

Based on manufacturers’ published data for self-adhered air and water barrier membranes, elongation less than 200 percent is considered inadequate to accommodate expected movement at joints in the substrate. Elongation above 600 percent is considered excellent.

Generally, the elongation of the membranes increased after freezer exposure. Water and UV exposure had mixed effects on the membranes’ elongation, typically increasing it for the vapor-permeable ones and decreasing it for vapor-impermeable membranes. Accelerated aging generally resulted in a slight decrease of the elongation.

Further, the product that exhibited tearing (splitting) at the self-adhered flashing also exhibited poor elongation during the testing. Figure 7 summarizes the results.

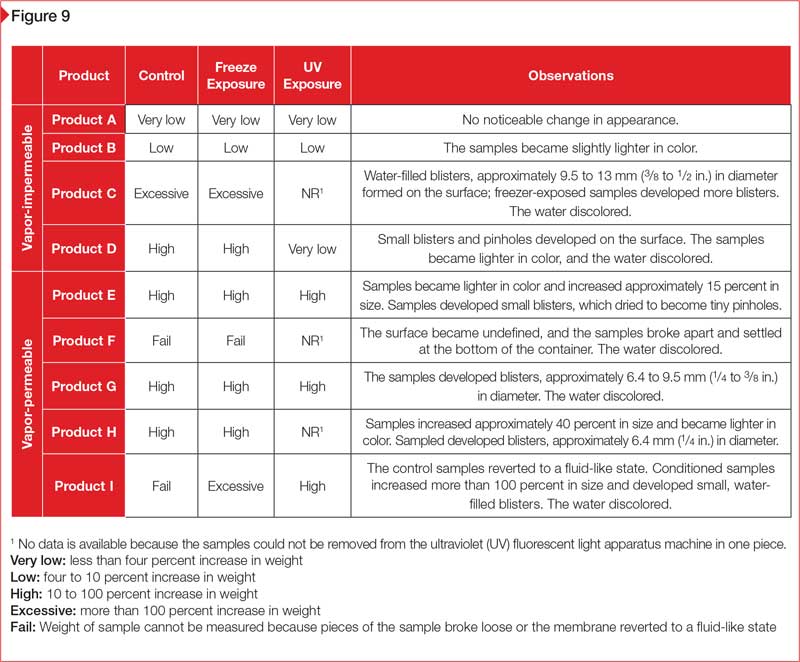

Water absorption rates should be as low as possible—less than four percent by weight is ideal and greater than 10 percent is unacceptable. During testing, some membranes more than doubled in weight, which is excessive. Membranes that reverted to a fluid state or softened to the point where pieces broke away from the sample are considered to have failed.

All the vapor-permeable membranes increased in weight more than 10 percent. Two of the vapor-impermeable membranes increased in weight less than 10 percent.

The effect of additional cure time was also tested by examining other samples at week increments beyond the manufacturer’s stated initial cure time. Additional cure time was found to have no significant effect on the percent increase in the sample’s weight.

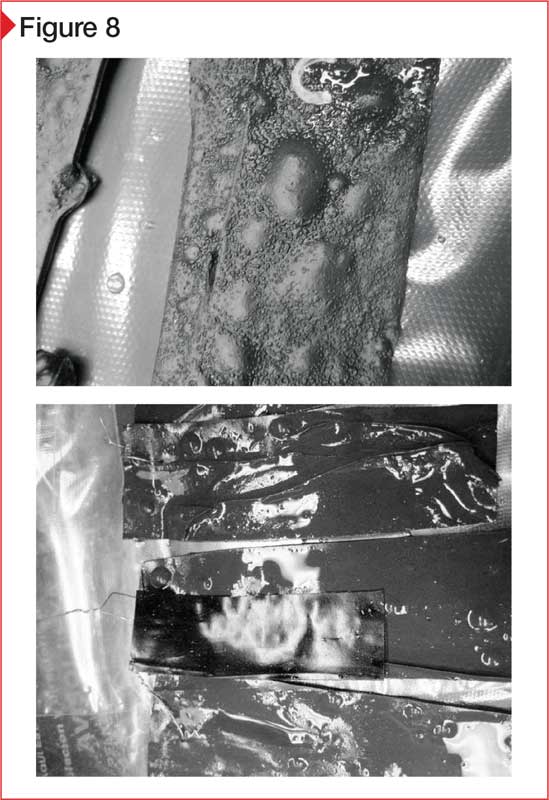

The team noted (confirmed) membrane failures observed in the field, such as large water-filled blisters and membranes returning to a fluid-like state and sliding of the wall, correlated with membranes that exhibited high or excessive water absorption during testing (Figure 8). Figure 9 summarizes the results of the water absorption testing.

Conclusion

The test results showed significant differences among these products, particularly when measuring for water absorption and, in some cases, elongation. When the design intent is to use the membrane as a water-resistive barrier within the exterior wall assembly’s ‘wet zone,’ only a few of the vapor-impermeable membranes seem appropriate based on water absorption values of 10 percent or less. All the vapor-impermeable membranes failed the water absorption tests, with some membranes dissolving or falling apart in water.

Many of the products tested were asphaltic-based membranes. New fluid-applied air barriers are constantly entering the market. Membrane manufacturers are now developing and beginning to market membranes with silicone and polyether chemistries, among others. These newer membranes are not included in the testing described in this article, but they too would likely have a range of results.

New products are often appealing and can offer initial cost savings to owners and contractors. After the cladding is installed, membrane deficiencies may go unnoticed for years, causing hidden structural damage. Once discovered, repairing the waterproofing (and any other damage) will be costly. Designers should be wary of products that do not have an established track record or sufficient testing to help predict long-term performance.

Katherine S. Wissink, PE, LEED AP, is a senior staff I at Simpson Gumpertz & Heger (SGH). She joined the firm’s building technology department in 2006 after receiving a master’s degree in structural engineering from Cornell University. Wissink is a member of SGH’s practice group for exterior wall systems, along with ASTM Committee E06–Performance of Buildings. She can be reached at KSWissink@sgh.com[7].

Laura R. Kellett is a staff II at SGH, joining in 2008. She is part of the building technology department, and a member of SGH’s practice group for exterior wall systems. Kellett graduated from Cornell University with a bachelor’s degree in civil engineering. She can be contacted via e-mail at LRKellett@sgh.com[8].

Stephen S. Ruggiero, PE, is a senior principal with SGH. He has worked in its building technology department since 1977, and specializes in exterior wall systems. Ruggiero is the former leader of SGH’s national practice group for exterior wall systems, remaining an active participant. He can be reached at ssruggiero@sgh.com[9].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2012/12/Opener.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2016/02/CS_Dec2012_HR-71-fig1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2012/12/CS_Dec2012_HR-71-fig2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2012/12/CS_Dec2012_HR-72-fig3.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2012/12/CS_Dec2012_HR-72-fig4.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2012/12/CS_Dec2012_HR-73-fig5.jpg

- KSWissink@sgh.com: mailto:KSWissink@sgh.com

- LRKellett@sgh.com: mailto:LRKellett@sgh.com

- ssruggiero@sgh.com: mailto:ssruggiero@sgh.com

Source URL: https://www.constructionspecifier.com/testing-fluid-applied-air-and-water-barriers/