Thinking Big: Seven considerations when specifying large insulating glass units

by Katie Daniel | August 31, 2015 3:45 pm

[1]

[1]by Steve Marino

Insulating glass (IG) units—or IGUs—have come a long way in the past 70 years. Originally mass-produced in the early 1940s to decrease noise and increase passenger comfort in Pullman railroad cars, the technology has transcended that mobile application and become integral to a business much more stationary in nature—the building industry.

Driven by the principles of sustainable design, IG units are being designed with increasing sophistication. They are incorporating multiple cavities, coatings, and tints, and are being combined with laminated glass, acid-etched patterns, spandrels, interlayers, and other finishes to boost glass performance while achieving stunning visual effects.

Adding to that complexity is growing demand for large IG units—in other words, those that are 4.5 m2 (50 sf) or larger. Improvements in glass manufacturing and the performance of solar-control, low-emissivity (low-e) coatings, together with building information modeling (BIM) and advanced design software, are making curtain walls and large IG units that were once difficult to conceive easier to integrate into building designs.

Unfortunately, such progress has done little to make large IG units easier to engineer, fabricate, deliver, and install. There are still plenty of logistical challenges to overcome, particularly considering the customized nature of most large IG unit designs. With those factors in mind, this article examines seven issues that need to be addressed with glass fabricators and glazing contractors when designing or specifying large IG units for a building envelope:

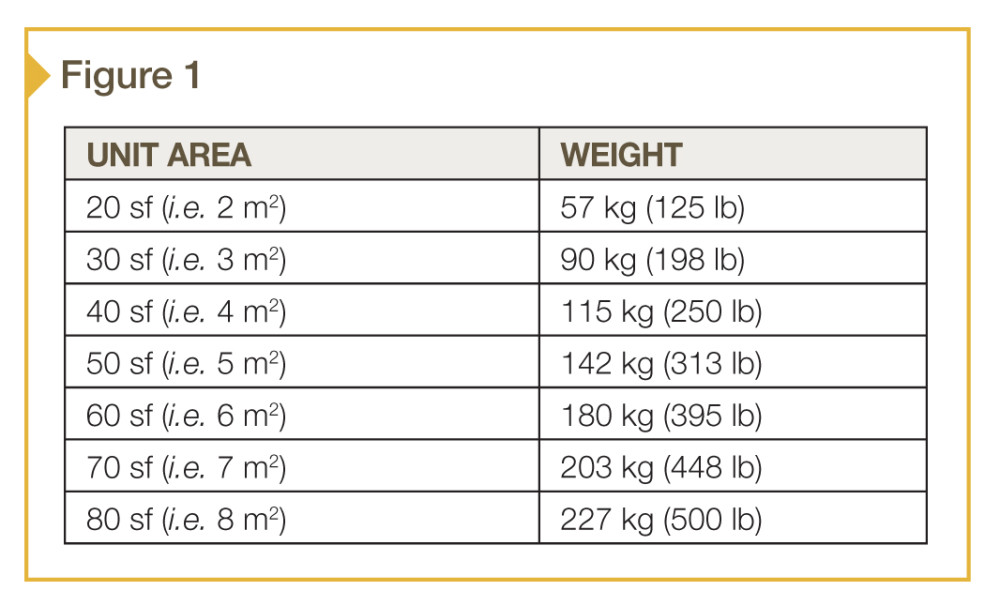

1. Weight

The sheer heft of large IG units make them difficult to handle and, therefore, more vulnerable to damage during fabrication, shipping, and installation. A standard 25-mm (1-in.) IG unit with two lites of 6-mm (¼-in.) glass and a 12-mm (½-in.) air space weighs about 29.5 kg (65 lb) per 1 m2 (10 sf).

Figure 1 shows the calculated weight of a variety of standard 25-mm (1-in.) IG units. Due to the specialized challenges working with oversized IG units, architects are best-served to collaborate with glass fabricators and glazing contractors who have the demonstrated capabilities, equipment, and experience to handle them. Possible solutions include:

- special heavy-duty lift assists;

- heavy-duty oversize conveyors;

- oversized furnace-tempering capability;

- oversized IG unit assembly capability; and

- oversized lamination capability.

All fabricating equipment can handle larger sizes of glass with a heavier weight limit that is not typical in the industry.

[2]

[2]2. Heat-treating

Large IG units have expansive surface areas that make them vulnerable to wind loads and thermal stress caused by extreme temperature variation from the center-of-glass to edge-of-glass.

As a consequence, fully tempering or heat-strengthening glass is recommended for large IG units to enhance their resistance to these threats. Unfortunately, the trade-off for greater strength is increased potential for visual distortion in large IG units caused by bowing or warpage that is inherent to the heat-treatment process.

Most glass fabricators who work with large IG units know how to accommodate the increased potential for bowing and warping. Nevertheless, architects should work with glass suppliers to establish acceptable tolerances for these variables as part of the bid and specification processes.

[3]

[3]3. Wind load

As mentioned, large IG units are more likely to require heat-treating of the glass to resist breakage at specified wind loads, yet heat-treated and untreated (annealed) glass will always exhibit equal amounts of deflection (physical bowing) when exposed to the same wind load.

For this reason, large IG units must be designed to limit center-of-glass deflection to a degree that not only retains support of the IG unit where glass panels meet the framing, but also does not alarm building occupants on excessively windy days.

To ease such concerns, most glass manufacturers recommend IG units be designed to limit center-of-glass deflection—the amount of bowing from the edge of an IG unit to its center—to 19 mm (¾ in.) or less.

Figure 2 compares center-of-glass deflection calculations for six IG unit sizes at various assumed wind loads using ASTM E1300, Standard Practice for Determining Wind Load Resistance of Glass in Buildings.

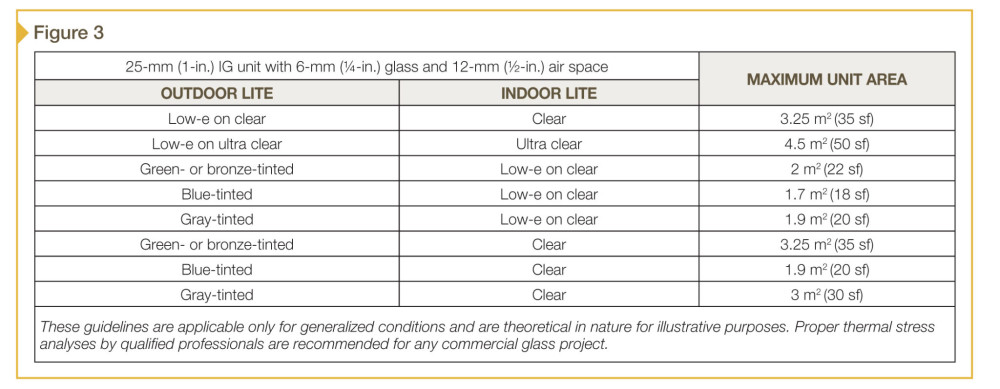

4.Thermal stress

Large IG units typically require heat-treatment to resist thermal stress, particularly when tinted and/or high-performance low-e glass is specified for one or more lites. This is due to the fact tinted glass absorbs heat and low-e coatings reflect heat, which can exacerbate variations in temperature from the center to the edge of an IG unit, increasing the likelihood for heat-differential-related breakage.

Early design considerations involving the use of any glass product, especially large IG units, should always include an evaluation of potential thermal stress breakage. Most major glass manufacturers provide online tools that enable specifiers to execute their own thermal stress analyses. However, due to the number of potential variables involved, the glass manufacturer, glazing contractor, glass fabricator, or a qualified building engineer who is familiar with anticipated project conditions should perform such calculations.

[4]

[4]Potential conditions that can influence thermally induced stresses and overall probabilities of breakage include:

- outdoor lite selection (i.e. clear, tinted, or coated glass);

- indoor lite selection (i.e. clear, tinted, or coated glass);

- IG unit size (i.e. glass thickness, width, and height); and

- installation conditions.

With respect to installation conditions, factors include:

- building altitude;

- winter temperature range;

- outdoor frame design and color;

- adjacent reflecting surfaces (e.g. woods, blacktop, bodies of water, snow, other buildings);

- outdoor shading patterns (e.g. shading devices, overhangs, site orientation, nearby buildings);

- indoor shading patterns (e.g. blinds, shades, interior walls and partitions); and

- heating register locations.

Figure 3 shows the maximum recommended surface area for resisting thermal stress for eight common IG unit configurations incorporating annealed (non-heat-treated) glass that have generalized conditions acting on them. Any IG unit of the same configuration larger than the one specified in this table should be heat-treated. Thorough thermal stress analyses using actual conditions for the related project always are recommended.

[5]

[5] [6]

[6]5. Fabrication

Whether processed manually or on ultra-sophisticated automated assembly lines, large IG units present challenging issues architects need to discuss with glazing contractors and glass fabricators. Before awarding a project, one should ensure suppliers have safeguards for dealing with the following:

- handling and placement of spacers that are highly flexible due to their large size;

- ruptures in spacer welds and seals caused by large-spacer flexibility;

- uniformity and press of primary seals;

- consistent production and orientation of heat-treated glass to both minimize reflective distortion, and avoid damage to glass and/or coated surfaces inside the sealed air/gas cavity due to contact caused by process-related glass-bowing;

- handling of large glass units; and

- safe storage and handling to prevent damage to, or failure of, primary sealant due to sheering stresses associated with large IG units.

[7]

[7]6. Field-related issues

Careful handling and storage of glass is paramount on any jobsite, but especially so with large IG units because of their size and expense. Again, architects are well-served to address shipping, handling, and storage issues with glass fabricators and contactors as part of the bidding and specification processes, including:

- personal safety—one must ensure adequate labor power and proper equipment will be available to keep the worksite safe;

- primary seal protection—protocols need to minimize the risk for damage to, or failure of, the primary IG unit seal caused by shearing stresses during handling and storage;

- handling-related glass damage—acknowledging large IG units are more likely to be damaged during handling due to their size, one must work with the glass supplier to accommodate such eventualities; and

- glass-to-glass contact—a contingency plan should address latent damage to large IG units caused by glass-to-glass contact when subjected to changes in temperature and/or barometric pressure.

7. Glazing issues

As with shipping and handling procedures, glazing systems themselves must be properly designed to accommodate large IG units. For instance, metal members must effectively support and retain the unit’s weight, and setting blocks must be properly sized and located to support its weight as well.

Large IG units also should be designed to prevent excessive deflection of the horizontal sill, which can cause water to accumulate in the center of the unit and hinder good drainage through the weep system. Excessive deflection of adjacent horizontal members should be avoided to minimize the potential for glass damage and breakage.

More information about standard industry glazing practice guidelines are published in the Insulating Glass Manufacturers Alliance (IGMA) North American Glazing Guidelines for Sealed Insulating Glass Units for Commercial and Residential Use, and the Glass Association of North America’s GANA Glazing Manual.

Conclusion

Architects favor glass because of its unparalleled aesthetic and performance advantages. No other material can provide building occupants and building owners with such an enviable combination of views, daylighting and environmental performance. Building designs that incorporate large insulated glass units highlight those benefits. Along with more sophisticated design and manufacturing capabilities, this explains their increased popularity.

By working closely with glass suppliers experienced with large IG units to address the issues outlined above, architects and building owners can reap the rewards of these extraordinary products while minimizing potential headaches throughout design, production, shipping, handling and installation.

Steve Marino is a technical support manager at PPG Flat Glass, and has been with PPG Industries for 30 years, holding various positions in manufacturing and quality for both automotive and architecture glazing. Marino is an active participating member of both the Insulating Glass Manufacturers Alliance (IGMA) and Glass Association of North America (GANA), and sits on multiple committees and task groups for both organizations. He chairs GANA’s Tempering Division Technical Services Committee. Marino can be reached at smarino@ppg.com[8].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/photo1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/think-big-figure-1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/PUC2_057.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/think-big-figure-2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/think-big-figure-3.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/PPG_3381-01.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/IHG_6642-low-res.jpg

- smarino@ppg.com: mailto:smarino@ppg.com

Source URL: https://www.constructionspecifier.com/thinking-big-seven-considerations-when-specifying-large-insulating-glass-units/