Specifying Wood Veneer: Expert Tips for Achieving Desired Aesthetics and Controlling Cost

Wood veneer is an inherently unique finish, with colors, grains, and naturally occurring features that differ from species to species and log to log. For designers, wood veneer adds warmth and character that other finishes can’t match. But for specifiers, veneer can often present challenges in meeting design expectations and managing costs.

To get a final door finish that checks all the boxes, specifiers must know which wood species will get them the color, texture, and grain pattern the designer wants, and which cuts, matches, and assemblies will fine tune those features. To guide these choices, Forte Opening Solutions, a designer and manufacturer of commercial architectural wood doors, offers the following primer on wood veneer for door surfaces along with expert tips on specifying for more predictable outcomes.

Wood Species: Colors, Grains & Stains

Before specifying the wood species, the first and most important step is choosing a door manufacturer that offers factory finishing, as this choice has major implications for final appearance and quality control. Compared to field finishing that occurs after a door is installed, Forte™ factory finishing is completed in a dust-free, climate-controlled environment prior to delivery, ensuring color, texture, and sheen consistency meet aesthetic and long-term performance expectations. Forte also offers select stains from a curated collection of on-trend colors selected to complement a wide range of interior styles and bring out the natural beauty of wood veneer doors.

Next is selecting a wood species with a natural color and grain that aligns with the design goals. The openness of wood grain has a direct impact on how well stain is absorbed and the consistency of the final finish. Generally, open-grain woods emphasize texture and handle dark stains well, while closed-grain woods provide a refined appearance best suited for light or clear finishes. A selection of wood species, including color, grain, cost, and finishing tips from Forte’s wood veneer experts can be seen in Table 1.

Table 1

| Species | Veneer Color | Grain | Cost | Spec Tip |

| Natural Birch | Light brown to yellow sapwood with darker, red-tinged brown heartwood | Closed grain with an irregular grain pattern and fine texture; strong contrast between sapwood and heartwood | $ | Highlight variation with lighter stains or subdue contrast with medium/dark stains for a more uniform look |

| Red Oak | Wide range from light/medium brown to dark red | Coarse texture with an open grain and, when plain sliced, a pronounced cathedral effect from early- and late-season growth | $$ | Open grain is receptive to stain; performs best with medium, golden, or dark tones |

| White Oak | Light to medium brown with olive undertones | Tighter and more dense grain than red oak with a bold cathedral pattern from seasonal growth bands, depending on cut | $$$ | Absorbs stain well; medium/dark stains enhance depth; clear finishes emphasize character |

| White Birch | Consistently light due to predominance of sapwood | Fine texture with closed, linear grain; may show a mix of cathedral and straight patterns depending on cut | $$ | Very versatile — takes any stain; stain choice can amplify or mute the grain |

| White Maple | White to light golden or reddish brown (sapwood dominant) | Smooth, fine texture with a closed, linear grain | $$ | Best with clear or light stains; darker stains may blotch without conditioning |

| Cherry | Light pinkish to reddish brown; darkens to deeper red-brown | Uniform, medium-pore texture with straight grain, gentle waving figure, and subtle cathedral | $$$ | Takes stains well; best with a clear coat to preserve warmth and highlight natural darkening |

| Walnut | Light to dark chocolate brown heartwood; sometimes with gray undertones | Finely textured with semi-open to open straight grain, accented by a waving figure and cathedral pattern depending on cut | $$$$ | Stains evenly; works best with medium/dark stains; naturally lightens with age |

| Mahogany | Light pinkish brown heartwood that darkens to rich red-brown | Medium to coarse texture with straight, open grain; may show figured patterns | $$$$$ | Open grain accepts stain readily; darker stains minimize natural color variation |

Cut: Plain, Quarter, Rift or Rotary

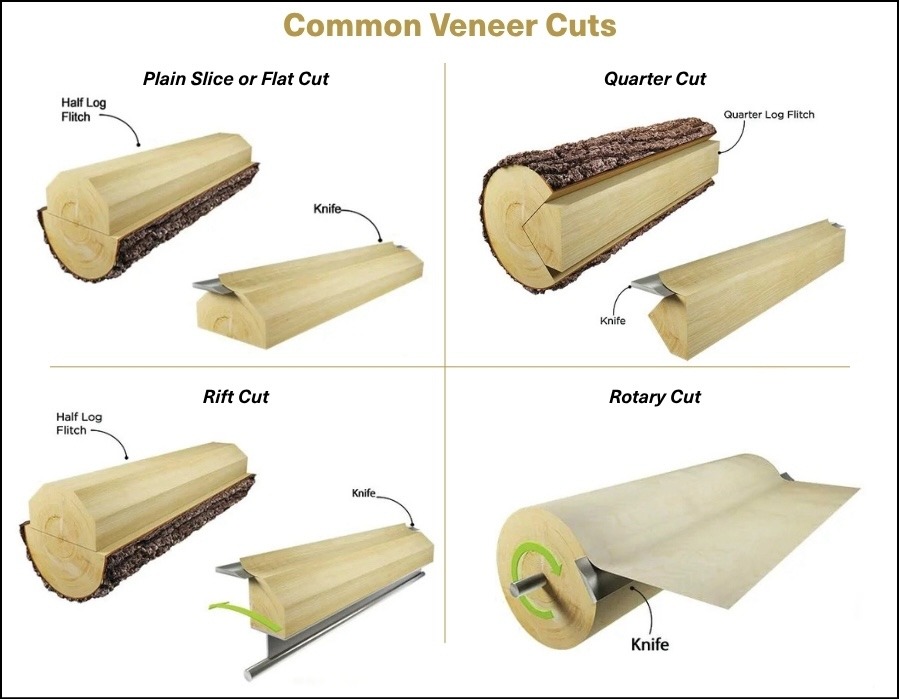

Another key point in aesthetic control is the cutting technique used to produce the veneer leaf. Each wood species has a default cut that balances log yield with veneer quality and appearance, but the default cut may not always produce the visual effects the designer wants. In those cases, specifying a different cut can provide tighter control over the veneer’s appearance, but it will also increase its price.

Forte can provide most veneer cut requests, including the four most common cuts, to give designers and specifiers greater freedom with grain patterns and textures. The following cuts can also be specified for wood paneling, millwork, cabinetry, and casework to coordinate other elements of interior design.

Plain slice (flat cut) is the most common method of cutting wood veneer. The log is cut in half lengthwise, and the veneer knife slices parallel to a line through the center of the log. This method produces a surface with a distinct cathedral grain pattern (arch-shaped figures) in the center of the veneer leaf and straighter grain toward the edges. Plain sliced veneer provides optimal recovery from the log, making it one of the the most cost-effective cuts.

Quarter cut is done by first sawing the log into quarters lengthwise, then slicing the veneer at a right angle to the growth rings. This produces a straight, linear grain pattern that is much more uniform than plain slicing. In certain species, such as oak, quarter cutting can also expose the medullary rays, creating a shimmering flake figure that adds visual interest.

Rift cut is a specialized method most often used with oak. The log is quartered, and then the veneer knife slices at a 15° angle to the quarter lines. This minimizes the appearance of medullary rays and the flake figure in quartered oak and instead yields a straight, tight linear grain pattern. Because the cutting angle reduces the amount of usable veneer from the log, rift cut is one of the most expensive veneer cuts.

Rotary cut is the most cost-effective, and when paired with darker stains, it can minimize random patterns and deliver an appealing aesthetic on a tighter budget. The wide veneer sheets feature organic grain patterns and dramatic swirls created by cutting the log on a lathe. This cut maximizes yield but produces the greatest variation, making leaves more difficult to match.

Spec tip: For modern interiors that require a consistent look, specify rift or quarter cut to minimize variation and produce a sleek, architectural appearance. For cost savings with more natural variation, plain sliced is a reliable choice. Reserve rotary cut for projects where economy outweighs predictability, or where bold, organic patterns are desired.

Match: Book, Slip, Random or Continuous

Matching refers to the arrangement of individual wood veneer leaves to create a larger sheet with a specific pattern. Just like cutting creates a distinct pattern in the veneer leaf, matching is the larger pattern created by the arrangement of multiple leaves.

Book matching is the most common matching method in which alternating leaves are flipped like the pages of a book. This creates a mirrored, symmetrical pattern that highlights natural cathedrals and maximizes yield, but it can produce a striped “barber pole” effect where the leaves meet.

Slip matching places the veneer leaves side by side without flipping. The result is a uniform appearance with no barber pole effect. Slip match works especially well with quarter cut or rift cut veneer.

Random matching positions veneer leaves without regard for alignment, pattern, or sequence to create a casual, solid wood appearance.

Continuous or end matching creates the effect of one uninterrupted piece. While visually impressive, this matching method is limited by veneer length and alignment can be challenging.

Spec tip: If consistency is the priority, choose slip matching with quarter or rift cuts. If decorative symmetry is desired, use book matching, but prepare the client for the possibility of barber poles. For a rustic look, random matching is appropriate. Reserve continuous or end matching for high-end feature entries across multiple components such as transoms.

Assembly: Arranging Veneer Across the Face

Assembly is the final arrangement in which matched leaves are laid across the door face. This step determines the overall symmetry and balance and impacts cost.

Running match applies the veneer in continuous sequence until the door panel is complete. Veneer widths may vary, and the final leaf may be narrower than the rest. Running match is the most economical but least controlled.

Balance match: All veneer leaves are the same width prior to trimming to create a uniform overall appearance.

Center balance match uses an even number of equal-width leaves centered on the door panel for perfect symmetry. This is the most visually refined and costliest option.

Pair and set match ensures that two or more doors are matched in color and grain. The match is usually created using sequential leaves.

Blueprint match involves manufacturing and numbering doors to maintain precise continuity across a project. This is the most expensive option and requires early coordination with the millwork supplier.

Room match doors are made to be visually compatible within a space. While effective for cohesive design, room match presents challenges for long-term maintenance since exact replacement later is nearly impossible.

Spec tip: Choose running or balance match for standard projects where cost control is critical. For boardrooms, lobbies, or other high-visibility areas, specify center balance or blueprint match. If clients want multiple doors to match, make them aware of the replacement challenge.

Sample Size Is Key In Predicting the Final Aesthetic

Wood veneer sampling is an important early step in understanding what a final door face will look like. While some distributors provide small 2-by-4-inch samples for submittals to approve color and cut, this size makes it difficult for designers to visualize the full effect of the specified choices. Since wood is a natural, variable material, small samples are risky for predicting final appearance. For this reason, Forte recommends obtaining larger 8-by-10-inch samples for submittals and approvals. While this size does not fully display the match and assembly, it does a better job of representing the color and grain of the final veneer and ensuring it will meet expectations once the project is complete.

Careful Specs Lead to Beautiful Results

Veneer doors offer the warmth and sophistication of natural wood with the stability and performance required for commercial use. They make it possible for designers to achieve a high-end look at a fraction of the cost of solid wood while maximizing yield from every log for greater resource efficiency. With knowledge of the species, cuts, matches, and assemblies available and the most effective ways to combine them, specifiers can meet design intent with precision. When paired with factory finishing and thoughtful sampling, wood veneer doors from Forte Opening Solutions deliver lasting style, consistent quality, and a final aesthetic with no surprises.

For a deeper cut into wood veneer, including veneer grades and characteristics, check out the article Grain, Grade, and Great Design: What You Need to Know About Wood Veneers.

All information listed in this section was submitted by IBP Solutions LLC Forte.

Kenilworth Media Inc. cannot assume responsibility for errors of relevance,

fact or omission. The publisher does not endorse any products featured in this article.