Best practices for applying commercial IGU glazing

Pre-glazing considerations

When selecting glazing products, specifiers can feel more confident about their specifications if manufacturers have taken certain pre-glazing considerations into account. This includes manufacturers’ shop drawing review, a pre-installation procedures meeting and inspection of the glazing system, and breather or capillary tubes.

For the shop drawing review, project-specific glazing shop drawings or fenestration system details can be submitted to the IGU sealant manufacturer for review. The glass fabricator should also be consulted regarding the glass construction, strength, and compliance with specifications and glazing details. In addition, the sealant manufacturer should be consulted for assurances of sealant compatibility and strength, approval of spacer shim materials, and for recommendations on optimum joint configuration and proper adhesion to glass and support members.

Before glazing, application guidelines from the IGU fabricator, sealant, or other glazing material suppliers should be reviewed with the on-site glaziers or shop personnel setting the glass in fenestration systems.

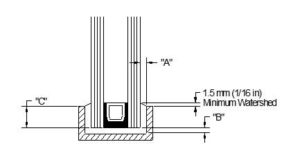

As glazing begins, fabrication tolerances should be checked. For example, the glazing should be free of debris and obstructions, weep holes should be open and free of obstructions, and glazing surfaces should be free of moisture, dirt, grease, oil, and other contaminating materials.

Care should be taken that screws, bolts, rivets, and weld fillets do not protrude into the glazing channel which would reduce the minimum required face or edge clearances.

Further, all joinery, connectors, screws or bolt heads, rivets, and water dams should be effectively sealed; all steel or wood glazing rabbets and contact areas of dissimilar materials should be effectively primed; and setting blocks, weep baffles, and edge blocks should be properly located in the glazing channels.

In inspecting the glass, the IGU should be measured for proper dimensions, recognizing fabricator-published tolerances. Also, glass edges, sealant uniformity, and coating quality should be inspected according to the glass manufacturer’s guidelines.

For VIG, consider inspection of pillars, or objects that keep lites from touching, and the pump-out port, or area where the air is pulled to create the vacuum, to make sure they meet the fabricator’s specifications. The fabricator should also set questionable glass aside for inspection. For breather or capillary tubes, consult the IGU fabricator for proper installation procedures.

Glass protection and cleaning

Since it is difficult to protect glass from damage during construction, it is important to check and daily document glazing materials if building teams need to provide evidence of post-glazing damage. In addition, a number of best practices should be followed to best protect the glazing on the jobsite.

- Paint, plaster, and sealant spills or splashes should be removed from the glass immediately.

- Protection should be provided to prevent weld splatter, sand blasting, concrete alkaline deposits, or other caustic materials from contacting glass surfaces as these materials will permanently damage glass surfaces.

- Protective coatings or release agents applied to the glass should be evaluated for compatibility to the IGU, the glazing system, and the fenestration system’s frame.

- Glass surfaces should be cleaned soon after installation and on a regular basis if surrounding construction leaves deposits such as concrete runoff, rust stains, sealant bleeding, etc., on the glass.

Knowing IGU glazing guidelines

IGUs can be a performance asset to a commercial project. Specifiers can refer to guidelines such as those found in IGMA TM-3000 to ensure they are making informed decisions when it comes to selecting IGUs.

Notes

1 See the Fenestration and Glazing Industry Alliance (FGIA) standard, IGMA TM-3000, North American Glazing Guidelines for Sealed Insulated Glass Units for Commercial and Residential Use.

2 Refer to AAMA/WDMA/CSA 101/I.S.2/A440-22, North American Fenestration Standard/Specification for windows, doors, and skylights (NAFS), store.fgiaonline.org/pubstore/ProductResults.asp?cat=0&src=A440-22.

3 Refer to ASTM E2190, Standard Specification for Insulating Glass Unit Performance and Evaluation, www.astm.org/e2190-19.html.

4 Refer to ASTM E1300, Standard Practice for Determining Load Resistance of Glass in Buildings, www.astm.org/e1300-16.html.

5 See American Society of Civil Engineers/Structural Engineering Institute, ASCE/SEI 7, Minimum Design Loads and Associated Criteria for Buildings and Other Structures, ascelibrary.org/doi/book/10.1061/asce7.

6 Visit LMN Architects, the Seattle Convention Center Summit Building, lmnarchitects.com/project/washington-state-convention-center-addition.

7 Learn more about the Viracon, Architectural Glass Gallery: taxation building, www.viracon.com/projects/view/id/1468/.

8 For more information, visit Vitro Architectural Glass, Acrisure Stadium, projects.vitroglazings.com/acrisure-stadium-formerly-heinz-field.

9 For more information, visit Vitro Architectural Glass, David L. Lawrence Convention Center, projects.vitroglazings.com/david-l-lawrence-convention-center.

10 Visit EFCO, 1717 Innovation Center, www.efcocorp.com/galleries/detail/662.

11 See 365 Nicollet, www.365nicollet.com

Author

Author