Caring for glazed architectural terra cotta

Temporary stabilization

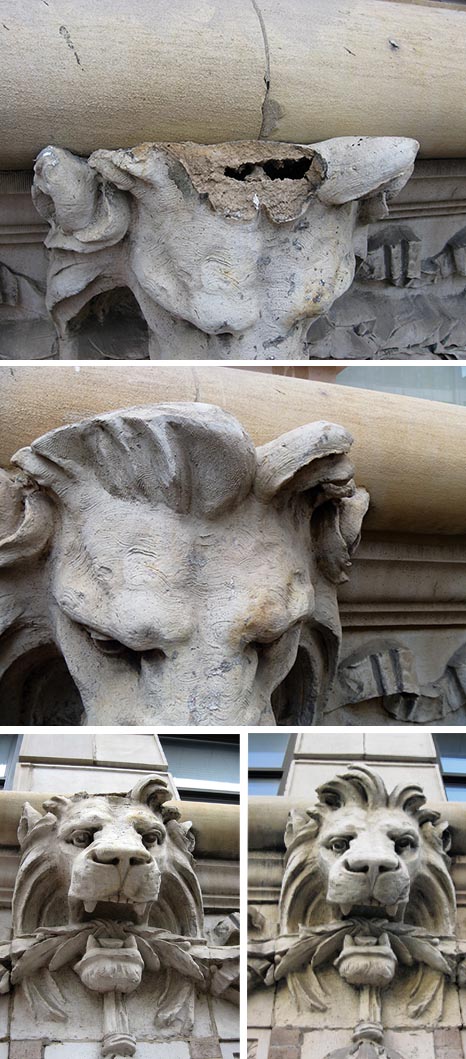

Where deterioration is so severe pieces may fall from the building, temporary stabilization or replacement may be necessary to protect public safety. Particularly in urban areas or locations with high seismic activity, code compliance—and civic responsibility—dictate the immediate securing of identified hazards. Until a permanent solution can be implemented, nylon netting and metal strapping are commonly used to secure unstable pieces.

Where hazardous deterioration necessitates removal of units, leaving open gaps can increase the structural load on the remaining pieces and provide an avenue for water infiltration. When fabrication time, budget considerations, or seasonal factors delay restoration, temporary replacement can prevent further deterioration until the long-term repair is completed.

In-kind replacement

Since glazed architectural terra cotta tends to be a complex, interlocking system, it may be difficult or even impossible to remove damaged units without destroying them. If a terra cotta unit is very loose or severely deteriorated, it may be necessary to replace it, rather than salvage and restore it. It is best to completely remove all of the deteriorated original material, as leaving half-units is not likely to yield a satisfactory repair.

During production of new terra cotta units, meticulous design, specification, and quality control are imperative. Both structural and visual compatibility are major considerations, and specifications must account for factors affecting not only strength, but also durability.

Key considerations include:

- compressive strength;

- absorption (i.e. saturation coefficient/cyclic freezing testing);

- glazing compatibility with the terra cotta and resistance to crazing;

- uniform joint widths and unit dimensions;

- tolerances for face dimensions and warping/chipping of the finished face;

- surface color/texture/shape/size/profile matched to existing units;

- finish defects/imperfections; and

- low coefficient of moisture expansion (for new units set into existing terra cotta).

Given the variegation, intricate textures, and sculptural forms of historic terra cotta, most replacement pieces must be custom-cast. These hand-crafted units are expensive, and have lengthy delivery times, on the order of eight to 10 weeks. Machine-made, standardized terra cotta units may be available for some pieces, such as plain ashlar blocks, and provide a faster, more economical solution. While more uniform than hand-made terra cotta, these factory-produced units tend to be less durable and have thinner and more brittle glazing, with color less rich and varied than its historic counterparts.

For both machine- and hand-fabricated terra cotta, it is important to obtain material samples and quality control units from each firing, to test compressive strength and absorption characteristics and to confirm the properties of special glazes. To facilitate correct installation of replacement pieces, a unit numbering system should be used, both in shop drawings and on the units themselves.

Prior to the installation, the terra cotta pieces should be laid out in configuration in order to confirm dimensions and colors. Where possible, replacement units should be anchored similarly to the originals.

Replacement with substitute materials

While in-kind replacement is always preferable from a historic preservation standpoint, there are other viable options that may be appropriate where new terra cotta is unfeasible.

On the whole, substitute materials tend to offer faster manufacture and cost savings over replacement terra cotta. However, even closely matched alternatives may have a slightly different appearance than terra cotta; some are glossier, and concrete products tend to darken when wet. Unlike decorative elements or cladding, structural terra cotta may be difficult to substitute, as an entirely redesigned structural system may then be required.

Stone

Stone is durable and may be the best match for terra cotta that was originally cast and glazed to imitate natural stone. However, it weighs significantly more than terra cotta, and the cost may be just as high, especially where ornately detailed carving is involved.