The Circular Economy: How architects and designers can contribute to reducing waste

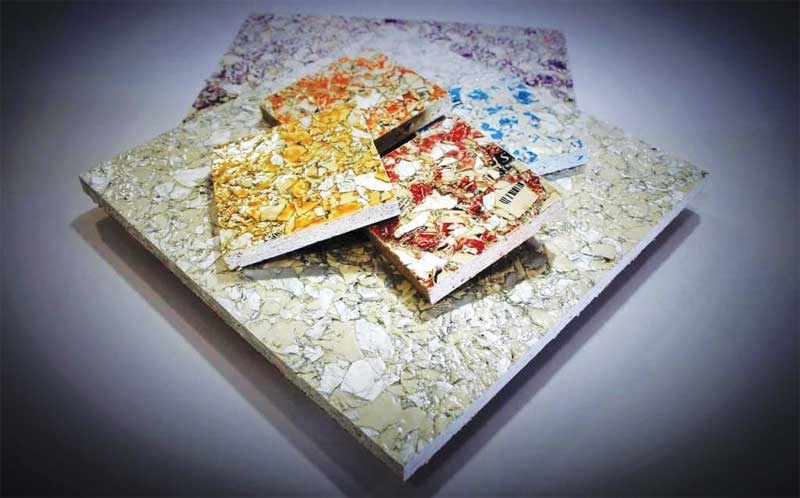

Photo courtesy The ReWall Company

Sourcing: Improving environment and communities

In a circular economy, reduction is the fundamental practice when sourcing materials. Materials sourced globally have large impacts on carbon dioxide (CO2) emissions, and negatively affect the atmosphere. In a 2017 report, the International Council on Clean Transportation (ICCT) found 87 percent of shipping emissions are attributed to international shipping activity, compared to only nine percent resulting from domestic transportation.

Obstacles

Recycled material markets are dictated by global market fluctuations, at times creating difficult situations for companies to predict and consistently maintain or gain market shares. Carpet is one industry affected by global material procurement. According to the annual report for Carpet America Recovery Effort (CARE), 1.5 billion kg (3.4 billion lb) of carpet were discarded to landfills in the United States. As carpet mainly comprises petroleum-based materials, oil prices often dictate the market for recycling. As prices drop, the market available for processed recycled carpet materials dissolves.

Solutions

Sourcing with a circular economy model can create immediate cost-savings for shipping and freight. Specifiers should look for locally-sourced products. LEED v4 credits can be earned for products sourced within 161 km (100 mi) under the Regional Priority category. This credit is emphasized by valuing local materials at 200 percent of their base contribution costs. The Living Building Challenge (LBC), an initiative by the International Living Future Institute (ILFI), requires 20 percent or more of the construction budget materials to come from within 500 km (310 mi) of the project site. Current programs and tracking systems are available for “carbon counting,” enabling design firms to demonstrate their environmental responsibility to potential clients. As more products and materials are sourced regionally, it inevitably improves local markets and increases employment. Additionally, LEED v4 credits are also available through procurement of materials with minimum recycled contents.

![This insulation features post-consumer recycled materials (repurposed inorganic carpets, organic cotton clothes, and polyethylene terephthalate [PET] fibers) without formaldehyde, making it easy to handle and safer for installation. Photo © Phillip Van Nostrand](https://www.constructionspecifier.com/wp-content/uploads/2018/06/CarpetCycle_Quiet-Tech_SafeInstallation.jpg)

Photo © Phillip Van Nostrand

The circular economy emphasizes durability, quality, and recyclability for sustainable product production. Designing for durability helps ensure an increased life cycle in construction applications. Manufacturing for durability and longevity is the first aspect necessary for properly recycling in a closed-loop or circular economy. Quality products in the circular economy scenario will be durable, safe, and easily reused or reclaimed at the end-of-use stage.

The guidelines set by Healthy Building Network (HBN) for manufacturing safe products is measured by limiting and optimally displacing all potentially hazardous chemicals. This is instrumental in ensuring products have minimal negative health effects to end-users, laborers, and the environment. High-performance features and non-hazardous components in products are the foundations for applicability to—and evaluation of—a true circular economy.

Manufacturers who are actively participating in sustainability can be researched through databases such as HBN. (For more, click here.) Further, the Cradle-to-Cradle program aids in material selection that focuses on products’ life cycles.

Obstacles

Discovering information on manufacturing processes and products can be time consuming, as all information will not be readily available or fully disclosed. Further, verifications for sustainable manufacturing practices are not a government or industry mandate, which may make comparative shopping difficult, and companies not implementing circular economy manufacturing practices are not likely to promote it. Conversely, small companies innovating sustainably-manufactured products may not have the financial flexibility required to verify through third parties. The selection of manufacturers by design professionals will directly affect the percentage of demolition materials that can be reclaimed, reused, or recycled.

Solutions

By inquiring about sustainable manufacturing practices, designers and specifiers have the ability to drive change. The knowledge accumulated about the circular economy would enable design professionals to plan more efficiently on future projects. LEED v4 offers credits for selecting materials from manufacturers who have EPR programs as they have planned for their products to be re-channeled into the regenerative cycle of a circular economy.