Water, water everywhere: Low-carbon concrete’s water dilemma and what can be done about it

Water scarcity is no longer a distant concern but a rapidly escalating global crisis. Around the world, water availability is declining while water demands are rising. Regions that were once water-secure are now struggling to meet even basic needs, threatening the foundations of food security and public health. Agricultural systems are under mounting pressure as irrigation sources dry up, and millions face the risk of losing access to clean, safe drinking water.

Amid this crisis, a surprising contributor emerges: the construction industry. Water is essential for life and critical for mixing, placing, and curing concrete. Water is the most widely consumed material in the world and is also one of the four primary ingredients in concrete, the second most consumed resource globally, after water itself.

Outside of highly water-stressed regions, the prevailing focus on cement’s carbon footprint has led to the vital conversation around water-wise construction being overlooked. Many new mix designs paradoxically demand more water as the industry races to adopt low-carbon alternatives to traditional Portland cement. Like the mariner adrift on a sea of undrinkable water, the construction industry now finds itself surrounded by solutions that promise lower carbon—but demand more of the very resource we are running out of.

Climate change, population growth, and shifting precipitation patterns tremendously stress global water systems. Within 25 years, growing water scarcity could threaten more than half of the world’s food production. Meanwhile, architects, engineers, contractors, and specifiers—key players in reshaping the built environment—are being encouraged to use low-carbon concrete alternatives that have more variability than traditional cement mixes. Beneath low-carbon concrete’s green promise lies a less understood risk: many of these mixes require more water in the mix to remain workable, which can compromise strength, amplify volumetric instabilities, promote shrinkage cracks and crazing, and shorten the concrete’s service life.

Efforts to reduce carbon emissions, including environmental product declarations (EPDs) that do not consider long-term durability, may unintentionally result in more fragile structures with a shorter service life and increased repairs. This outcome can undermine environmental benefits, stress ecosystems more, and increase construction and facility maintenance costs.

Lifting the albatross

The good news? The problem is well understood, making it possible to address. Elevating water resource management as a key design and construction objective offers a pathway to resolving the tension between carbon reduction and water conservation. Projects such as Kendrick Elementary School in Waco, Texas—an area facing real water shortages—provide valuable insight and leadership to inform approaches elsewhere. The following sections examine the underlying challenges and outline key strategies to help balance these competing demands.

Concrete’s permanent water footprint

Water used to make concrete becomes permanently unavailable. Once it reacts with cement, it cannot be extracted. Although concrete can absorb and release moisture, the water involved in the chemical reaction is permanently bound. This creates a lasting “water footprint,” unlike the “carbon footprint,” which can eventually be offset over hundreds of years as the environment reabsorbs carbon from cement production.

Why?

Irreversible hydration

The hydration of cement is a chemical reaction that creates new compounds. These compounds are stable and do not revert to their original components (cement and water) under typical conditions.

Water of convenience

Concrete contains “water of convenience,” excess water not used in the hydration process. This water can evaporate or be removed, but it is not the same as the water that has chemically reacted with the cement.

Porosity

Concrete is porous, meaning it has tiny spaces that can absorb and retain water. This absorbed water can evaporate, but it does not mean it is extracted from the hardened concrete matrix.

Curing versus drying

Curing is the process of maintaining moisture for the chemical reaction to complete. Drying is the process of water evaporating from the concrete after the reaction is finished. While drying can remove excess water, it does not reverse the hydration process.

Recycling concrete

While water cannot be extracted from concrete, the material can be recycled by crushing it and reusing the aggregate in new concrete or other construction applications.

Water demand in traditional low carbon concrete

The shift toward using record volumes of Portland Limestone Cement (Type 1L or PLC) and supplementary cementitious materials (SCMs)—such as fly ash, slag, calcined clays, and injected CO2-based additives—has fundamentally changed how concrete behaves. These materials do not react like cement, often increasing water demand for hydration and flowability, or reducing particle packing efficiency—requiring more water to fill voids and maintain workability.

Unfortunately, many in the architecture, engineering, and construction (AEC) community have not updated their approaches to design, documentation, training, or on-site execution. As a result, there is a tendency to treat new low-carbon concrete as if it were traditional concrete. The consequences include unnecessarily extended schedules due to delayed strength gain, reduced durability, additional mitigation measures, contractor dissatisfaction with workability, low compressive breaks, increased risk for all stakeholders, and—perhaps most ironically—the potential for higher global warming potential (GWP) due to shorter life cycles.

At the same time, the call from many ready-mixed concrete suppliers and trade organizations are encouraging the removal of water-to-cementitious material (w/cm) ratios from specifications, allowing more water to be consumed in efforts to improve workability for their contractor customers—despite understanding that too much water lowers strength, increases porosity, and can cause immediate durability issues (e.g. cracking, deflection, freeze-thaw failure).

As a result, hundreds of thousands of cubic meters (millions of cubic feet) of permeable, low-durability concrete are placed every year—material that often requires immediate or early-life repair. Such remedial work is costly, time-consuming, and environmentally detrimental, undermining the very sustainability goals that low-carbon concrete is intended to achieve. While higher water content is often justified as a means to improve workability and meet the water demand of SCMs, it is worth noting that water can be a high-margin component for ready-mixed concrete suppliers. Since concrete is sold by weight, this dynamic can create potential conflicts of interest when advocating for the removal of contractual w/cm ratio limits.

Understanding SCMs and their water demands

Each SCM affects concrete differently. Fly ash, for example, may reduce early strength gain and require more water for workability. Slag cement may delay set times. Other additives, including glass pozzolan or carbon-injected solutions, can increase complexity in early hydration stages.

These differences matter. A lack of understanding often leads to adding excess water in the field—at the batching plant, in transit, or during placement. This additional water raises the w/cm ratio, often weakening the concrete matrix and increasing permeability, shrinkage, and surface cracking.

Eric Traffie, a certified contractor and member of Bomanite New England, the American Concrete Institute (ACI), and the National Concrete Refinement Institute (NCRI), states:

“Sure, adding water is easy—but if you’re not careful with how much, it can come back to bite you. Too much water might make the pour go smoother, but it can weaken the concrete long-term and lead to expensive fixes before the building even opens.”

Sidonie Immler, a partner at Foster + Partners, says: “Sustainable developments need to be looked at holistically. Solutions do not exist in isolation. Whole-systems thinking must include water management, particularly in the concrete industry.”

Case Study: PLC in practice

Portland Limestone Cement (Type 1L or PLC), now the leading type of cement available in the U.S. and Canada, contains five to 15 percent limestone—compared to a maximum of five percent in Type I and Type I/II cements. If substituted pound for pound, this can reduce CO2 emissions by 10 to 15 percent. While some industry participants have claimed minimal performance differences, the reality on job sites has proven more complicated. Contractor complaints regarding reduced finishability (“stickier mixes”), shorter set times, and batch variability persist, and all too often, the short-term solution is simply adding more water.

Concrete is sensitive to small changes. While properly deployed PLC can improve particle packing, it can also alter hydration rates, reduce early strength, and increase surface porosity. Concrete suppliers frequently increase PLC content within their mixes by five to 10 percent to achieve comparable cement content to that experienced with Type I and Type I/II cement mixes. While avoiding the risk of low-strength breaks, they are negating the carbon reduction benefits promised by advocates of Type 1L cement. The question remains whether the industry is truly reducing its carbon footprint while maintaining concrete quality, or merely trading one performance challenge for another.

Water management: The critical factor

Water management remains one of the most overlooked—and most critical—elements of sustainable concrete production. On many projects, water is introduced at multiple stages of the process, often without submittals and oversight. Whether added to improve slump, offset delays in placement, or adjust mix temperature, each unmeasured addition has the potential to radically alter the concrete’s fresh and hardened properties. Even seemingly minor increases can change setting time, reduce strength, and compromise durability.

Addressing this challenge requires more than just better procedures—it requires education. Everyone involved in the process, from mix designers and quality control (QC) technicians to pump operators and finishing crews, must understand the role water plays in modern concrete, particularly in mixtures that incorporate SCMs. These materials can be more sensitive to water content, making proper management essential for achieving the desired performance. Without this shared understanding, even the most carefully engineered mix can yield inconsistent, disappointing results in the field.

The Goldilocks zone: Optimal hydration for superior concrete

Concrete needs water to hydrate cement, but too much water weakens performance. Getting the w/cm ratio “just right” is essential for strong, durable concrete. The American Concrete Institute (ACI) and Canadian Standards Association (CSA A23.1) recommend keeping w/cm ratios below 0.50–0.55 for most applications. For dense or high-performance concrete—such as industrial slabs, watertight structures, or exterior paving exposed to freeze-thaw cycles and deicing salts—the ratio is often limited to 0.40 or less. According to Abram’s Law, higher w/cm ratios reduce strength and increase porosity, shortening service life. In aggressive environments like seawater or sulfate exposure, a w/cm ratio of 0.40–0.45 is commonly specified.

Excessive water leads to:

- Reduced strength (ACI 211.1)

- Increased cracking and shrinkage (ACI 224R)

- Segregation and bleeding (ACI 302.1R)

- Lower freeze-thaw and chemical resistance (ACI 318)

Forces shaping water use in concrete

Finding the “Goldilocks zone” for water content is crucial for concrete performance, and achieving the right economic balance in water valuation is equally essential for sustainable construction practices. According to the World Resources Institute (WRI), water prices in most regions significantly undervalue this vital resource, typically covering less than half the true cost of water infrastructure and environmental externalities.

Building standards have established more stringent water-to-cement ratio limitations to counter these economic systems that artificially favor water-intensive concrete solutions. These technical requirements function as regulatory safeguards against excessive water use while incentivizing concrete formulations with superior durability.

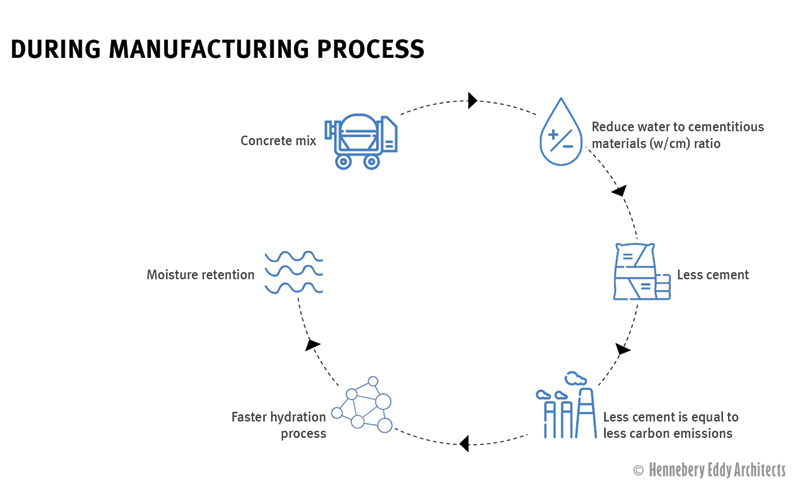

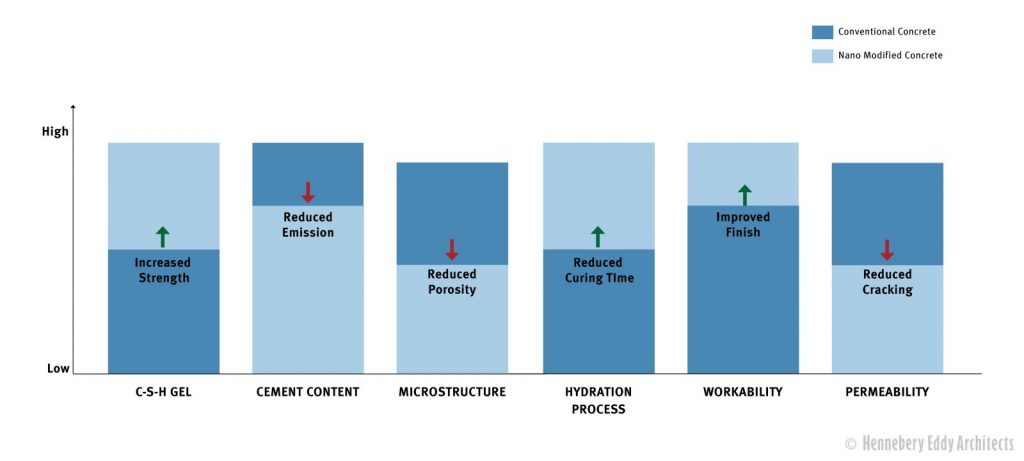

Enhancing hydration with nano-modified concrete

Cement hydration is the reaction between cement and water that forms hardened concrete. It dissolves cement particles, creating compounds like calcium silicate hydrate (CSH) and calcium hydroxide (Ca(OH)2) that bind the concrete. This process is crucial for concrete’s strength and durability.

SCMs replace a portion of the cement in concrete mix designs to reduce concrete production’s overall “carbon footprint” while maintaining or improving desirable performance characteristics. The inclusion of SCMs in concrete mix designs must account for the water content balanced against the design attributes of concrete performance.

The past 20 years of sustainable design have focused mainly on reducing the carbon emissions associated with cement production using the easiest solution to reducing cement content: maximizing the use of SCMs and, more recently, using Portland Limestone Cement (PLC). There has been minimal consideration for alternative solutions for cement reduction in concrete and water reduction using materials that improve contact between the cement particles and the available water for hydration.

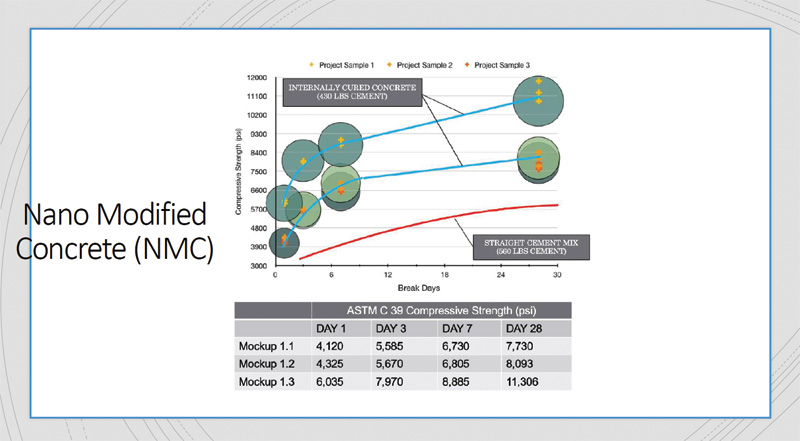

Nano-modified concrete uses tiny particles like nano-alumina, nano-clay, nano-platelets, nano-silica, and carbon nanotubes. These particles improve cement hydration by increasing the surface area for reactions, enhancing hydrolysis throughout the matrix, reducing the number of pores created, and reducing mix friction between particles. This leads to increased workability, reduced water demand, and stronger, more durable concrete. NMCs can be deployed in conjunction with or without traditional low-carbon mix designs.

International standards support lower w/cm ratios

Across the globe, major codes and standards consistently emphasize the need to limit water-to-cement ratios to improve strength, durability, and sustainability:

- ASTM C94 / ACI 318 (USA)—Requires low w/cm ratio for strength and long-term durability.

- EN 206 (Europe)—Sets maximum w/cm ratios for various exposure classes, including carbonation and chloride resistance.

- BS 8500 (UK)—Supports EN 206, reinforcing low w/cm ratios for durability.

- IS 456 (India)—Recommends maximum w/cm ≤0.50 in aggressive environments.

- AS 1379 / AS 3600 (Australia)—Prescribe w/cm ratio limits for sulfate, marine, and freeze-thaw exposures.

- NZS 3101 (New Zealand)—Provides durability targets similar to Australia’s, with clear w/cm ratio limits.

- DIN 1045-2 (Germany)—Emphasizes impermeability by specifying low w/cm ratios.

- PN-EN 12390-8:2019-08 (Poland/EU)— Supports findings that lower w/cm ratios reduce permeability.

- JIS A 5308 (Japan)—Specifies limits on w/cm ratios according to exposure and durability requirements.

Water-wise solutions in Waco, Texas

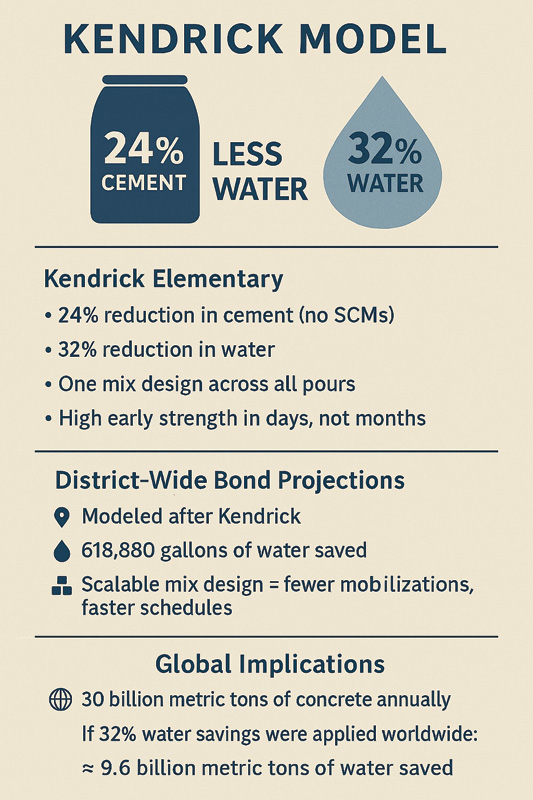

Waco, Tex., is quickly becoming a model for sustainable, water-wise concrete. After seasonal fly ash shortages forced the district to use all-cement concrete mixes at the recently completed high school, Gloria Barrera, chief of facilities and operations for the Waco Independent School District, and their designer, O’Connell Robertson, were determined to find a better solution for the next new build, Kendrick Elementary School. Engaging a concrete consultant, the design team explored new options and gravitated toward nano-modified concrete (NMC) technologies as a solution to their challenges. Following extensive research and early design-phase planning, the team implemented a single NMC mix design for all site and building concrete, updated specifications, provided for additional testing to ensure accountability and peace of mind, offered training for the local subcontractor and supplier communities, and established an economical, sustainable maintenance plan that included a path for the district to eliminate future needs for stripping and reinstallation of high GWP clear coats and sealers on their interior concrete floors.

- 24 percent cement reduction without the use of SCMs

- 32 percent reduction in water use

- One mix design for all site and building concrete

- High early strength in days, not months

- Avoided fly ash dependency

- Fewer subcontractor mobilizations

- Accelerated schedule and early building occupancy

- Use of NMC concrete systems for a more stable mix

- Reduce shrinkage, crazing, and surface cracking

- Safer floors through testing and concrete refinement

- Elimination of resinous materials on the walking surfaces

- Reduce overall install and facility maintenance costs to the owner

Water savings was a surprising metric—not originally on the team’s priority list. Traditional 20,684 kPa (3,000 psi) and 27,579 kPa (4,000 psi) concrete mixtures typically use w/cm ratios between 0.45 and 0.55. This is significantly higher than the w/cm ratios targeted by ACI Committee 211 for durable high-performance concrete (HPC). It could be argued that the excess water in traditional mixes, while aiding workability, is the root cause of nearly all common concrete issues, including surface cracking, curling, crazing, shrinkage, and high permeability.

The core principle is simple: less water equals better concrete—as long as the cement particles are properly hydrated. Reducing water content to HPC levels has historically presented challenges with workability and finishability. This is where NMC admixtures and additional training again added value to the project. The chemical admixture alters the hydration process, allowing cement particles to hydrate efficiently. The result is a water-wise concrete mix with strength and durability comparable to high-performance blends—but with improved workability and shorter schedules.

Fortunately, the curing properties of the NMC admixture also greatly reduce water evaporation at the surface, locking moisture into the mix so cement particles have a readily available water source throughout the curing process. The nano-modified concrete reduced the w/cm ratio from 0.45 to between 0.36 and 0.40. As a result, the Kendrick Elementary project saved approximately 310,400 L (82,000 gal) of water and prevented an estimated 422 tonnes (465 tons) of CO2e emissions.

“The Kendrick project was an adventure worth the effort,” says Gloria Barrera. “Waco ISD was ready to step up to the challenge to control costs, improve quality, and reduce embodied carbon and water use. Our concrete is beautiful and far surpasses previous traditional approaches.”

A call to action

Concrete is not only the world’s most versatile construction material; it also serves as the bedrock of the built environment, both literally and figuratively. When comparing materials used in construction worldwide, concrete dwarfs all other building materials with a mass of 10 times greater than any other. From skyscrapers to bridges, dams to driveways, concrete is the undisputed titan of construction. When designed, specified, and placed properly, it offers significant sustainability benefits, as long as durability is not compromised.

Increasing water content—a growing trend when introducing new mix designs aimed at carbon reduction—is compromising durability and shortening the lifespan of concrete. This needless waste of water, stemming from treating a new material as if it were still traditional concrete, also squanders a valuable resource that many regions can no longer afford. It is crucial to challenge the misconception that “low-carbon” automatically equates to “durable performance.”

Education and training within the AEC industry will be more important than ever to navigate the complexities of emerging concrete solutions. Innovative approaches, like the nano-modified concrete used at Kendrick Elementary, offer a path to durable concrete with impressive sustainability achievements and water savings. Success stories like Kendrick will continue to move the industry forward.

Historically, cement reduction has been the main driver of sustainable concrete solutions. Yet, with escalating populations, ever-increasing concrete production, and failing concrete, water savings will emerge as a dominant sustainability concern in water-stressed regions of the world.

In the quest for sustainable concrete—where durability and resource conservation must align—the Ancient Mariner’s lament rings true: “Water, water, everywhere, nor any drop to spare.” It serves as a reminder to craft resilient structures that honor our planet’s need for lower greenhouse gas (GHG) emissions, long-lasting facilities, and the preservation of precious water resources.

Jarrod Sterzinger of O’Connell Robertson emphasizes: “Partnering with Waco ISD gave us the opportunity to explore sustainable strategies that support both construction goals and long-term stewardship. Through this collaboration, we identified the value of preconstruction education, and internal curing with nano-modified concrete as a solution that not only enhances performance and durability, but also significantly reduces embodied carbon and water use. It’s the kind of innovation that reflects a shared commitment to smarter, more responsible building.”

With every drop of water saved, the strength is set to last.

Resources

- For understanding lower w/c ratios, see “Highway Agencies and Industry Get a Helping Hand in Fighting Concrete Deterioration.” November, 2000. Accessed July 30, 2025.

- For more understanding of nano-modified concrete, see “Nano-modified Concrete Research.” Hennebery Eddy Architects, September 5, 2024. Accessed July 30, 2025.

- For ongoing research in nano-modified concrete (NMC), see “Recent advances in nano-modified concrete: Enhancing durability, strength, and sustainability through nano silica (nS) and nano titanium (nT) incorporation.

- For further reading on nano-additives in concrete, read Wei Tian et al., “Nano-Additives in Concrete: Influence on Mechanical Properties and Sustainability,” Cement and Concrete Composites, vol. 157 (2024). Accessed July 30, 2025.

- Refer to Ashraf F. Ashour et al., “Recent Advances in the Application of Nanomaterials for Improved Concrete Performance,” International Journal of Concrete Structures and Materials 17, no. 1 (2023). Accessed July 30, 2025 .

- To explore unconventional methods for reducing concrete’s carbon footprint, see “An Unusual Approach to Low-Carbon Concrete,” Green Building Advisor. Accessed July 30, 2025.

- For insights on the growing potential of low-carbon concrete, consult “Low-Carbon Concrete Solutions Are Showing High Potential,” AIA Architect. Accessed July 30, 2025.

- Read more about basic steps for making effective concrete in “Back to Basics: The Four Steps to Creating Effective Concrete,” The Construction Specifier. Accessed July 30, 2025.

- To learn more about water stewardship in high-demand sectors such as tech, visit “Water Stewardship: Tech and Microelectronics,” Alliance for Water Stewardship. Accessed July 30, 2025.

- For information on Texas’s current water challenges, see Jason Whitely, “Texas Agriculture Commissioner Sounds Alarm, Says Texas Is Running Out of Water,” WFAA, June 2023. Accessed July 30, 2025.

- To study more on global river basins with water scarcity, see Wang et al, “A triple increase in global river basins with water scarcity due to future pollution.” Nature Communications, February 2024. Accessed August 6, 2025.

- To delve into microstructural analysis of cementitious materials, see “Microstructural Characterization of Self-Compacting Concrete by Spectrometry,” Structural Concrete 19, no. 6 (2018): 1688-1701. Accessed July 30, 2025.

Acknowledgements

The authors would like to thank BWC/Built Wright, Miller Sierra, Langerman Engineering, One Source, Brightworks Sustainability, the Waco Independent School District, and the citizens of McLennan County for their hospitality and leadership—and everyone working to make the planet better.

Authors

Chris Bennett is a key advocate for developing sustainable concrete solutions to replace costly and outdated methods. His firm spearheads project teams in reducing both the economic and environmental impacts of designing and implementing advanced concrete systems.

Melody Fontenot, AIA, CSI, CCCA, CCS, iSCS, SCIP, is a senior specification writer with Conspectus Inc., based in Portland, Ore. A licensed architect with more than 20 years of experience, she specializes in project management, construction documents, and contract administration. Passionate about product research and specification knowledge, she strives to improve communication across the architecture, engineering, construction, and owner (AECO) industry. She can be reached at mfontenot@conspectusinc.com.

Maria McCain, MSc, LEED GA, TRUE Advisor, Fitwel Ambassador, Alliance for Water Stewardship PC, brings more than 15 years of holistic sustainability expertise to her work as a consultant at JLL, internal leader at NRDC, and adjunct professor. Her extensive experience includes target setting, green building, water stewardship, sustainable operations, and ESG data management for Fortune 500 companies. She holds an MSc from King’s College London and a BSc from West Virginia University. She can be reached via email at maria.mccain@jll.com.

Kyle Picket, USGBC, serves as director of special projects for the Verdani Institute for the Built Environment and as a senior advisor for USGBC California. He lectures on resource stewardship strategies for the built environment at universities and vocational schools throughout California. Picket is also co-founder and board vice president of the William Worthen Foundation, a 501(c)(3) public benefit corporation that conducts research and creates outreach initiatives on the planning, design, construction, performance, and beauty of the built environment. He can be reached at kyle@usgbc-ca.org.

Keith Robinson, RSW, FCSC, FCSI, is an architectural technologist and specifier in Edmonton, Alta., Canada. He teaches courses at the University of Alberta, advises several construction groups, and sits on numerous standards review committees for ASTM and the National Fire Protection Association (NFPA). He is internationally recognized for his work in developing sustainable concrete systems. He can be reached at specwriter@shaw.ca.

Ryan Stoltz, P.E., ISCS, LEED AP, is a licensed structural engineer, LEED Accredited Professional, and associate principal at Structures, a North American engineering firm based in Austin, Texas. He served as structural engineer for the Kendrick Elementary project in Waco, Texas. He can be reached at ryan@structurestx.com.

Rae Taylor, Ph.D., holds a doctorate in civil engineering and materials science from the University of Leeds, along with a postgraduate certificate in technology management from the Open University. Her research focuses on improving the environmental impact of construction materials, particularly through cement replacement materials and additives that influence cement microstructure. She can be reached at raemorristaylor@gmail.com.

Key Takeaways

Water scarcity is an urgent global crisis, and the construction industry is a major contributor due to its heavy reliance on water in concrete production. While low-carbon concrete alternatives like Portland Limestone Cement (PLC) and supplementary cementitious materials (SCMs) aim to reduce greenhouse gas (GHG) emissions, many of these mixes require more water, risking durability and increasing long-term costs. The lack of updated specifications and oversight often results in weaker concrete and early-life repairs. Case studies like Kendrick Elementary in Waco, Tex., show that innovative solutions—such as nano-modified concrete—can lower water and carbon usage while maintaining strength and workability. Managing water content and educating the architecture, engineering, and construction (AEC) industry on water-wise design is now essential. Sustainable concrete must balance durability with resource conservation to avoid trading one crisis for another.