Mass timber’s hidden carbon: The role of slash management

The use of mass timber in construction, which is gaining in popularity, is commonly thought to be carbon neutral—but is it? Corgan’s Research and Development group, Hugo, alongside the firm’s Sustainability team, Echo, conducted peer-reviewed research focused on identifying emissions in mass timber that result from harvesting. Explore slash management and why mass timber remains a more sustainable option than concrete or steel when considering carbon emissions.

A false positive

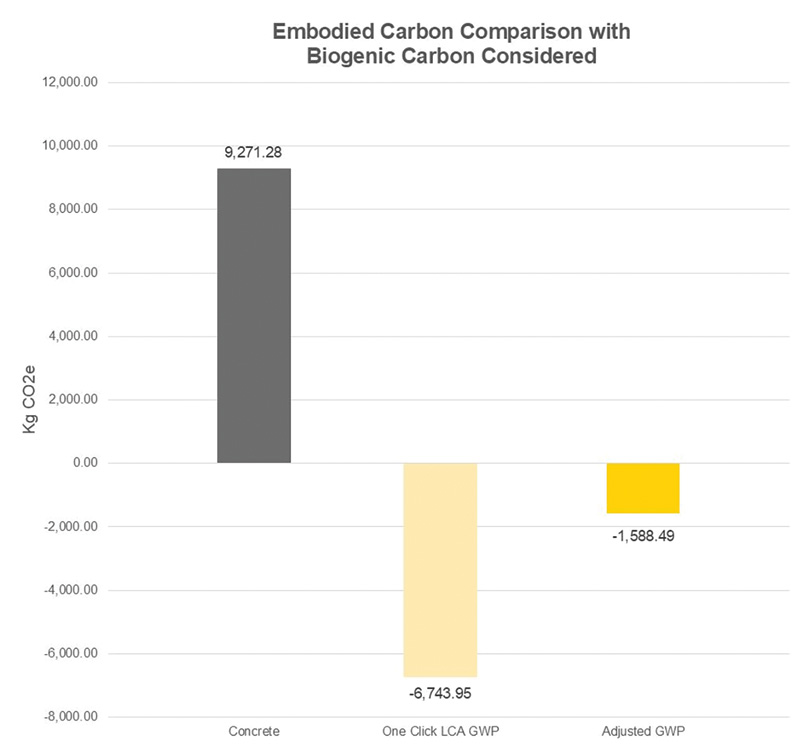

In the industry-wide effort to reduce its carbon footprint, AEC practitioners are paying close attention to embodied emissions, the carbon (and other greenhouse gas) emissions associated with the whole lifecycle of the materials used. Since these embodied emissions account for 20 percent of a building’s total energy use over its lifetime, they are an important target for minimizing the environmental impact of new construction and renovations. Mass timber has gained attention as a more sustainable alternative to standard concrete and steel construction for low to mid-rise projects. This is because mass timber is seen as being carbon-neutral, since trees naturally sequester carbon during their lifetimes. Due to the interest in this seemingly sustainable building material, the global demand for wood products is expected to quadruple by 2050.

However, a 2023 report from the World Resources Institute states there are emissions associated with mass timber that are not considered, particularly as it relates to timber harvesting practices. Corgan’s research seeks to fill this gap in understanding by identifying and estimating the emissions that are not typically accounted for in the harvesting of timber—the slash left behind on the forest floor and the way these materials are managed. The resulting report identifies tree species typically used in mass timber products, applies three common scenarios for managing the slash to determine the associated CO2e emissions, analyzes the impact of the transport of raw material on its embodied carbon, and makes recommendations to designers on how to manage this effectively. The research also resulted in the development of Corgan’s Mass Timber Carbon Calculator,1 a free-to-use tool that enables AEC professionals to easily improve their carbon emission estimates for mass timber projects.

Status quo and study scope

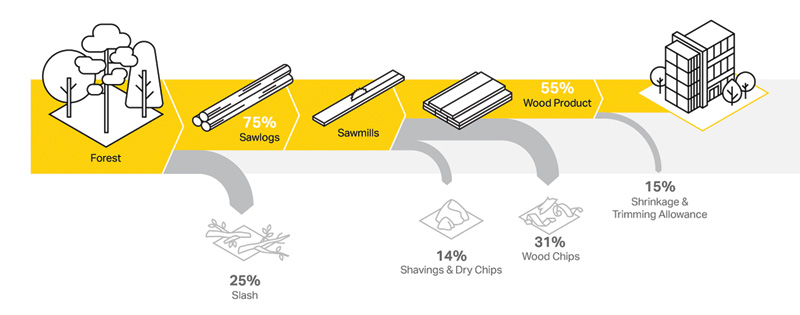

To begin, the study helps understand what is currently missing in the timber harvesting process in lifecycle assessments (LCAs). From extraction through processing, around 65 percent of a tree’s initial mass is lost—to slash in the forest, to shavings and wood chips in the sawmills, and to shrinkage and trimming allowance in the final wood product—meaning only 35 percent of what is cut down ends up in the building.

Of this, it is estimated that about 25 percent of the tree’s mass is lost to harvest residuals—the twigs, bark, and other small pieces of wood left behind that are known as slash. Since the carbon stored in slash is eventually released back into the atmosphere, these residuals represent a significant source of emissions that are not generally accounted for in mass timber buildings. However, the way slash is managed can play a significant role in the level of emissions. Corgan’s research includes three common slash management practices:

- Pile burning—Slash is gathered in piles, dried, and burned when conditions are favorable.

○ Pros: Clears woody debris quickly and reduces fire risk.

○ Cons: Releases 92–94 percent of the slash’s carbon content in a short period of time, significantly increasing emissions.

- Mastication—Leftover vegetation is ground into mulch that is left on site.

○ Pros: Useful where burning is difficult and enhances soil health.

○ Cons: Requires specialized, costly equipment and may cause soil compaction.

- Site composting—Leaving all slash and log leftovers in the environment, as is.

○ Pros: Returns nutrients to the soil and helps to prevent soil erosion.

○ Cons: Can hinder forest regeneration and pose a fire hazard if not managed properly.

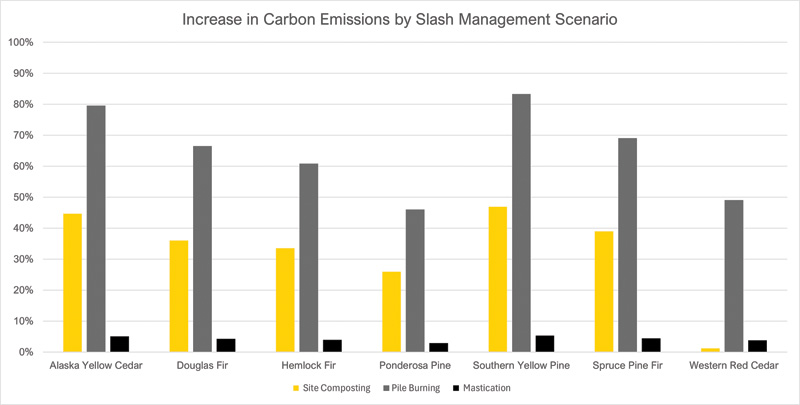

The study includes analysis of seven tree species most frequently used in mass timber construction: Alaska Yellow Cedar, Douglas Fir, Hemlock Fir, Ponderosa Pine, Southern Yellow Pine, Spruce Pine Fir, and Western Red Cedar. The Environmental Product Declarations (EPDs) for these wood products are sourced from OneClick LCA, as its A1 (extraction) to A4 (transportation) data includes detailed biogenic carbon storage information.

The study scope is defined by one question: What emissions are not fully accounted for in current mass timber carbon accounting models and how can designers properly integrate these into their carbon calculations?

Terms to know

∙ Embodied carbon—The greenhouse gases (GHGs) released during the extraction, production, and transportation of materials used in construction.

∙ Biological carbon sequestration—The ability of natural ecosystems to store atmospheric carbon. Carbon can be stored in plants, soil, wetlands, and the ocean. This research focuses on carbon sequestration of trees.

∙ Biogenic carbon—The result of sequestration (also called biologically sequestered carbon) is carbon that is stored in biological materials (like trees). Biogenic carbon is stored during the life of the tree and released when it is destroyed (decays, burns, etc.)

∙ Mass timber—A construction modality that uses a wood product, usually made from multiple wood panels nailed or glued together for extra strength, instead of steel or concrete. It is growing in popularity due

to its lower carbon footprint.

∙ CO2e—Carbon dioxide equivalent, a measurement used to compare the emissions of any GHG based on its global warming potential.

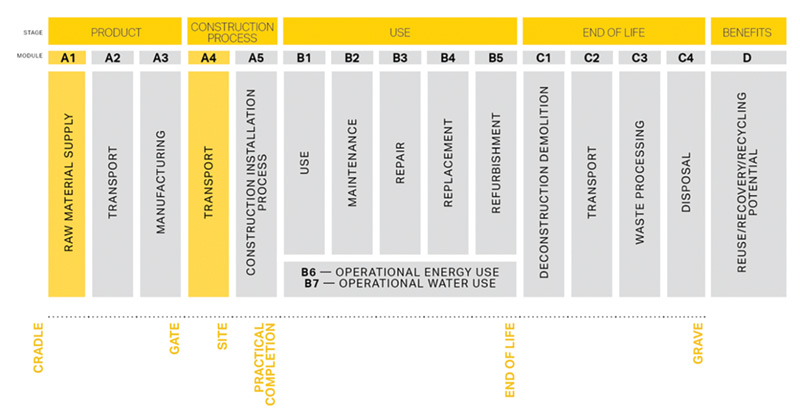

∙ Cradle-to-site—Stages A1 through A4 in a lifecycle assessment (LCA), starting where the raw material is harvested, transported, manufactured into a usable product, and transported again to the construction site.

∙ Slash—The material (branches, twigs, bark) left behind during mass timber harvesting; approximately 25 percent of the mass of the timber.

Method and model

After completing a comprehensive literature review using United States Department of Agriculture (USDA) forestry and academic databases, a model to account for carbon emissions associated with the three main scenarios for slash’s end-of-life was developed. The model considers several key factors:

- Below-ground biomass carbon stock—The carbon stored in the roots and soil of trees.

- Carbon emissions from slash—The residual biomass left after logging contributes to carbon emissions as it decays.

- Decay of CO2e over time—The gradual release of CO2e into the atmosphere as organic materials decompose.

The number of trees needed to produce cross-laminated timber (CLT) and glue-laminated timber (GLT) products was calculated using Revit and takes into account material losses that occur during the harvesting process. Striving to make the calculations as accurate as possible, the model employs established models and empirical data, detailed fully in the resulting white paper, to establish CO2e emissions for the A1 stage.

The model also includes the emissions from the shipping process of the raw material (A4). It calculates the number of trucks required to transport the material and uses the emission factor for a 36-ton (40-ton) heavy truck sourced from the United States Environmental Protection Agency (EPA). This emission value was then doubled to account for the round trip, as each truck returned to its origin. The A2 and A3 stages have been considered constant but have not been omitted. This approach ensures a comprehensive analysis of emissions throughout the entire supply chain.

While the model was developed to be as comprehensive and accurate as possible, there are certain limitations. In terms of method, the model relies on existing formulas, forestry data, and industry averages; it does not include on-site data collection, which may impact its accuracy. In terms of scope, the research is focused on the A1 through A4 phases, is restricted to regions within North America, and does not include sustainable sourcing practices other than slash. Recognizing these limitations, readers can better interpret the results and conclusions of the research.

Case study and findings

To demonstrate the practical use of the dynamic carbon accounting model, a case study was conducted. The theoretical building is a 20,067-m² (216,000-sf), six-story office building in Dallas, Tex., with mass timber structural elements. For this scenario, Douglas Fir was selected for the flooring and structural columns and Spruce was selected for the framing. The total volume of mass timber calculated in the case study was 3,264 m³ (115,250 cf).

The results show that effective slash management is crucial for maintaining the carbon sequestration benefits of wood products. The pile burning scenario consistently shows the highest carbon release, while the mastication scenario shows minimal carbon release. When compared to site composting, mastication releases less CO2e in the environment, as the materials are spread thinly over a large area, providing soil protection and nutrients.

The tree species used can also be an important factor in carbon sequestration; Hemlock Fir and Southern Yellow Pine showed large variations in sequestration potential depending on the slash management scenario applied, while Alaska Yellow Cedar, Douglas Fir, and Western Red Cedar consistently show high sequestration potential, especially under mastication. These species can be prioritized in reforestation and timber production projects to maximize carbon sequestration benefits.

The case study also analyzed CO2e emissions from transporting mass timber from different U.S. regions to a construction site in Dallas. As expected, emissions associated with transportation increase with distance. This exercise demonstrates the impact of a designer’s selection of wood species on transportation-stage emissions and hence overall embodied carbon. Though clients often prefer specific types of wood due to their cost or appearance, AEC clients and professionals should consider using local wood options when possible.

The case study confirms that while there are additional emissions associated with slash management that are not always accounted for, mass timber remains a better option than standard concrete or steel in terms of embodied carbon.

Conclusion

The efforts of Corgan’s sustainability and research teams are intended to start the dialogue on the true emissions of mass timber and provide some guidance to industry peers in accounting for often omitted biogenic carbon. The dynamic biogenic EPD calculator for designers allows them to see the impact of slash management scenarios for different tree species, leading to more sustainable project outcomes. The calculator enables near real-time decision-making for selecting lower carbon-intensive timber types at every project phase, facilitating discussions with contractors and engineers.

Looking ahead, the next step involves fostering industry collaboration and transparency about the slash created in the A1 stage. Designers can focus on sourcing materials locally, prioritizing low-carbon tree species, and being vigilant about slash management practices. Educating stakeholders, including clients, contractors, and suppliers, about the importance of reducing hidden embodied carbon and fostering collaboration to implement best practices throughout the project lifecycle is an important step in reducing the embodied carbon (and therefore the global warming potential) of mass timber buildings.

Ensuring all aspects of mass timber production are comprehensively evaluated and optimized for minimal environmental impact is a collective effort, but improving carbon accounting practices and promoting more sustainable construction processes is a vital step in the effort to build a more sustainable future.

Notes

1 See Corgan’s mass timber carbon calculator.

Authors

Varun Kohli, principal and director of sustainability at Corgan, has more than 20 years of experience integrating environmental analytics and sustainable design in architecture. His work spans urban resiliency, decarbonization, and large-scale projects worldwide. Passionate about ecology in the built environment, he champions net-zero design and climate adaptation. Kohli has collaborated with Yale Center for Ecosystems + Architecture (CEA) researchers on novel pedagogical models for environmental design, taught courses at Harvard GSD and RPI (CASE), authored a chapter in Energy Modeling in Architecture: A practice guide, published by RIBA, and serves on the Pokhrama Foundation board.

Mahdi Afkhami, PhD, is a design researcher with Corgan’s research and innovation team, Hugo. He leads evidence-based design strategies through mixed-method research, helping teams prioritize user needs and optimize outcomes. With expertise in user research, data science, and applied statistics, he explores emerging trends to deliver user-centric, future-ready solutions. Afkhami holds a PhD in Civil Engineering from Purdue University, an M.S. in architecture and sustainability studies from the University of Oklahoma, and a B.Arch. from the University of Tehran.

Key Takeaways

Mass timber is widely seen as a carbon-neutral alternative to steel and concrete, but uncounted emissions from harvesting and slash management challenge this assumption. Corgan’s research highlights the importance of slash management, species selection, and local sourcing—while offering a carbon calculator to help designers make more sustainable timber decisions.