Access granted: Building smarter data centers

Surging demand for artificial intelligence (AI), cloud computing, and other digital endeavors has made data centers one of the fastest-growing sectors in commercial construction. Data centers are the backbone of modern digital life, housing the servers and storage systems that run applications, manage data, and support online services. As such, facility construction demands unique safety and security measures as well as climate control and energy-efficient building design, which relies on high-performance materials, insulation, and technology for reducing energy consumption.

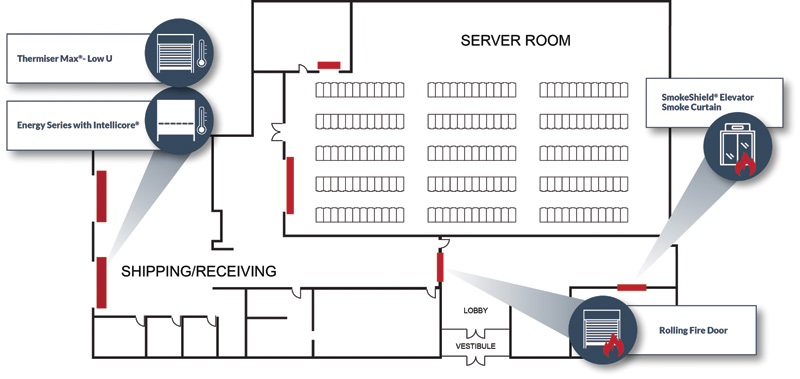

Two building components equipped to meet these diverse needs are the sectional door and the rolling door. Commonly used in warehouses, loading docks, and industrial facilities, these doors come in various designs that prioritize everything from passive fire protection to advanced insulation. Offering a wide variety of features, application flexibility, and ease of use, commercial doors check many boxes for data center designers and specifiers.

Doors at work: A data center example

To see where doors fit into data center design and what type works best for each application, consider a basic three-story layout that houses multiple secured pods for different tenants.

[Basic three-story data center design drawing with A, B, C, and D areas labeled.]

A—Ground floor loading bays

B—Upper floor loading bays

C—Data pods

D—Secondary spaces

Area A: Ground floor loading bays

Door: Energy-efficient sectional door

For a data center’s ground floor loading bays, which are standard areas for moving equipment, sectional doors featuring foamed-in-place polyurethane provide security and energy efficiency. During the manufacturing process, the foam is injected between the steel layers of the door, expanding to fill the door’s structure and frame and creating a more complete seal. Doors with three-layer construction have an exterior skin, an insulated core, and a steel backing, and the insulation bonds directly to the interior and exterior steel skins. Section joints are also thermally-broken. Doors designed with a polyurethane core can deliver R-values ranging from 12 to 27 and U-factors from 0.16 to 0.21. Specifiers can select insulated sectional doors with stucco or woodgrain embossed steel exteriors in flush, ribbed, or raised panel section designs. Additional options include the number and size of windows, as well as glazing options that range from clear and tinted glass to acrylic and polycarbonate. Maintenance-free steel finishes include standard white, black, tan, brown, and gray. Some manufacturers also offer thousands of custom paint options from well-known paint brands, as well as anodized finishes in bronze, dark bronze, black, and custom colors for full-view sections. Color-matched aluminum panels, wood-look finishes, and panel textures are also options.

Area B: Upper floor loading bays

Door: Low U-factor insulated rolling door

On the second and third floors, designers and specifiers can opt for low U-factor insulated rolling doors. U-factor measures the insulating ability of the entire assembly and includes all the materials in the assembly, whereas R-value only captures one part of a door’s construction. While upper-floor loading bay doors are accessed less frequently, their compact footprint, insulating properties, wind resistance, and sound transmission remain important specifications for ensuring consistent indoor temperatures and comfortable working conditions. Using an insulated curtain plus perimeter seals and strategic thermal breaks, low U-factor rolling doors minimize heat transfer through the door assembly when in the closed position. Specifiers can select insulated rolling door models with U-factor ratings as low as 0.532, the lowest available in the rolling door market. Low U doors are also sound transmission rated, providing control over interior noise levels.

A unique consideration for rolling doors used with upper floor loading bays is that they are accessed by cranes. To promote safety at these heights, specifiers should opt for motorized door operation instead of manual chain hoists to ensure safer, more stable door control. Models can be labeled for ASHRAE 90.1, IECC 2021, and California’s Title 24, and they can be configured to meet specific wind load requirements.

Area C: Data pods

Door: Rolling fire door

Inside a data center, rolling fire doors are a go-to for securing and compartmentalizing the data pods where servers and data storage equipment are housed. Rolling fire doors are engineered to slow the advance of smoke and flames between pods during a fire event. When integrated with a data center’s primary alarm system, rolling fire doors can automatically close when the building’s alarm is triggered or when power is lost. This is an important distinction from older-style thermally triggered rolling fire doors that require high heat to close the door and seal off an area. A thermal trigger is typically a fusible link that melts and releases the door’s holding mechanism, causing it to close; however, when temperatures become hot enough to melt the link, it is often too late to save the equipment inside from smoke damage. Thus, specifying a rolling fire door that can be integrated into a data center’s alarm system is recommended. Fire shutters with the same alarm-activated closure features are available for smaller spaces or counter applications.

Specifiers can also choose smoke and draft control features tested to the UL 1784 standard to ensure smoke is compartmentalized and does not spread throughout the facility and damage equipment in other areas. Fire protection rating options for rolling fire doors include 45 minutes, 90 minutes, three hours, and four hours.

Area D: Secondary spaces

Door: Elevator smoke curtain

For multifloor facilities with hoistways, integrated smoke curtains quickly and efficiently seal elevator door openings to reduce the advancement of smoke and hot gases up the elevator shaft during a fire. Available designs include magnetic-type curtains, which are held in place by magnets, as well as gravity-drop and motorized systems, which lower the curtain via gravity or motor mechanism. Curtains may also be transparent, providing first responders and evacuating occupants better visibility when the curtain is deployed. Other style options include vertical, horizontal, perimeter, and draft curtains. Depending on the curtain design, deployment may be triggered by a fire alarm system (the most common), smoke detectors, power loss, or manual activation. Some motorized models include a battery backup to ensure deployment during a power outage. The most compact offering available occupies less than 254 mm (10 in.) of headroom, and it complies with IBC 2003–2024 and other standards, including the AC-77, Acceptance Criteria for Hoistway Openings, as well as UL1784 and 864, ASTM E84, and California State Fire Marshal. Some models also meet UL 325 requirements.

Keeping cool is key

According to the National Renewable Energy Laboratory (NREL), the cooling necessary to protect sensitive data center equipment can represent as much as 40 percent of its total utility costs.1 While researchers are pursuing more efficient cooling solutions to reduce data center energy use, building components with high thermal resistance, air seals, and durability continue to be in demand.

Sectional doors are the standard for energy efficiency, but when these products do not meet building code requirements, such as the International Energy Conservation Code (IECC), low U-factor rolling doors are the optimal alternative. The low U-factor insulated rolling door is a prime example of a building envelope component that can help keep cooling costs in check. These doors typically feature double-wall slat construction, where the curtain is formed from two layers enclosing an insulated core. This assembly enhances both structural integrity and thermal performance. The core material is commonly polyurethane, polystyrene, or mineral wool.

In many standard rolling door designs, direct steel-to-steel contact between the inner and outer layers can create thermal bridges. To eliminate this, some manufacturers incorporate a thermal break to improve thermal isolation. Another potential source of thermal energy loss is the door guide system, i.e. the vertical steel tracks that guide and support the curtain during operation. While weather seals are typically specified to reduce air infiltration, they do not address thermal bridging at the steel-to-steel interfaces within the guide assembly. To resolve this, one manufacturer has developed a proprietary thermally broken guide design, integrating low-conductivity materials within the guide channels. These strategically placed breaks interrupt direct conductive paths and help maintain building envelope integrity—performance benefits that are especially important in heavily cooled data centers where every effort to control energy use counts.

Other door features to consider

When specifying doors for data centers, it is important to evaluate more than just passive fire protection or insulating capabilities. Doors offer a wide range of other functional, safety, aesthetic, and performance options that make them ideally suited for the data center environment. Additional features to consider include:

- Flexible installation—Sectional doors offer numerous track options to accommodate different installation scenarios, including front- or rear-mount tracks, vertical tracks, and high-lift designs. Likewise, steel rolling doors can be installed on the face of a wall or between jambs, making them suitable for interior and exterior walls. They are also compatible with common construction types, including masonry, structural steel, and drywall assemblies using wood or steel studs.

- High-cycle durability—Sectional doors are up to the task with springs offering up to 100,000 cycles for long performance life. In high-use areas, rolling doors can be equipped with a springless design rated for up to one million cycles for high performance, extending operational life and minimizing downtime for service or replacement.

- Seismic compliance—For data centers in earthquake-prone regions, doors can be evaluated for compliance with the ASCE 7-05 seismic requirements.

- Dependable seals—Sectional and rolling doors feature a bottom astragal that conforms to floor irregularities on both the interior and exterior sides of the door, limiting water and air infiltration, and ensuring a reliable fit without requiring excessive bottom limit adjustments.

- Wind load—Sectional and rolling doors can meet various wind load requirements, up to and including IECC-500 tornado shelter ratings for some rolling doors.

- Aesthetics and customization—Sectional door designs can be configured with two or four glass panels in sizes from 610 x 203 mm (24 x 8 in.) to full-view panels that maximize natural light. For rolling doors, some manufacturers offer powder coating in more than 180 colors, plus extra-durable finishes for doors exposed to harsher outdoor conditions.

As data centers grow in number, scale, and complexity, doors will continue to innovate too, playing an important part in securing, protecting, and insulating the technological future stored inside. In the next few years, commercial door manufacturers will likely introduce more secure access control systems embedded in door assemblies, such as biometric authentication, real-time monitoring, and integration with facility-wide security platforms. Construction and insulation materials, thermal break engineering, and perimeter seals will also continue to improve to meet increasingly strict energy efficiency targets. In a time powered by data, every door will be a critical component of the infrastructure that keeps modern life connected.

Notes

1 Refer.

Author

Heather Bender, director of commercial product marketing at Clopay Corporation, leverages 17 years of experience in manufacturing and building materials. Excelling in product management, she adeptly handles product inception to commercialization. Her role involves finding unique solutions for building owners and designers, highlighting her strategic and innovative approach to complex industry challenges. Bender can be contacted at hbender@clopay.com.