Chasing Leaks

Why we need a standard test for lateral water migration

Blindside waterproofing systems are buried out of sight, but when they fail, the consequences are anything but hidden. Water may migrate between the membrane and concrete, surfacing far from the entry point. This is known as lateral water migration, the movement of water between surfaces rather than through them. Watch how it happens.

Fixing the damage is costly, messy, and disruptive. And for design pros, the real challenge isn’t just picking a waterproofing system that claims to stop lateral water migration—it’s knowing which claims are actually backed by sound, credible testing.

In response, the industry is working toward a new standard for evaluating lateral water migration resistence. One manufacturer, Henry®, A Carlisle Company, is helping lead the charge. A proposed new ASTM test builds on years of in-house research and testing. Peter DiGiovanni, Technical Services Manager for Henry, helped initiate the effort to bring clarity to this long-overlooked performance feature. Bonnie Dauer, Technical Representative for Henry, chairs the ASTM workgroup now standardizing a test method.

The Hidden Risk: Lateral Migration Between Membrane and Concrete

In blindside construction, the waterproofing membrane is applied before the structural concrete is placed. Once the wall or slab is poured, the membrane becomes inaccessible. If water enters through a defect and the membrane isn’t sealed to the concrete, it can migrate laterally between the membrane and concrete interface.

“If a material is damaged or a seam gets missed, water doesn’t just leak, it may travel,” explains Bart Rowland, Director of Product Management at Henry. “Without a strong adhesive bond, there’s nothing to stop it.”

And that’s where things get complicated.

“You’re chasing leaks across a wall you can’t even see anymore,” adds DiGiovanni. “Injecting one area might not help if the water entered six feet away.”

Fully self-adhered membranes, including those with dual-bond technology, tend to localize leaks. They help maintenance teams find and fix problems quickly and cost effectively. But until now, the industry didn’t have a standardized way to test this kind of performance.

Inconsistent Testing

Most design pros are familiar with ASTM D5385, the standard hydrostatic pressure test for waterproofing membranes. It measures how well a membrane holds up when water is applied directly against a seam over an elongated crack or joint. Developed for post-applied systems, D5385 doesn’t evaluate lateral migration. This gap has led some manufacturers to create their own “modified” tests, often using setups that make it nearly impossible to compare results across products.

“Outside of presumably using the same test apparatus as D5385, it’s unclear what the “modifications” are. How the test samples are constructed, what is the specific test procedure, how is a failure reported, how is a pass defined, etc. are all unknowns and not reported or published in manufacturers’ literature.” says DiGiovanni.

Trying to compare results from these inconsistent tests? “It’s apples, oranges, and pineapples,” adds Rowland.

A Better Way: Developing a New ASTM Test for Lateral Water Migration

Henry experts recognized the need for consistency and took initiative. Several years ago, DiGiovanni, Dauer, and others began working to establish a formal ASTM method under Subcommittee D08.22. The goal? A reliable, transparent way to test how well membranes resist lateral water migration.

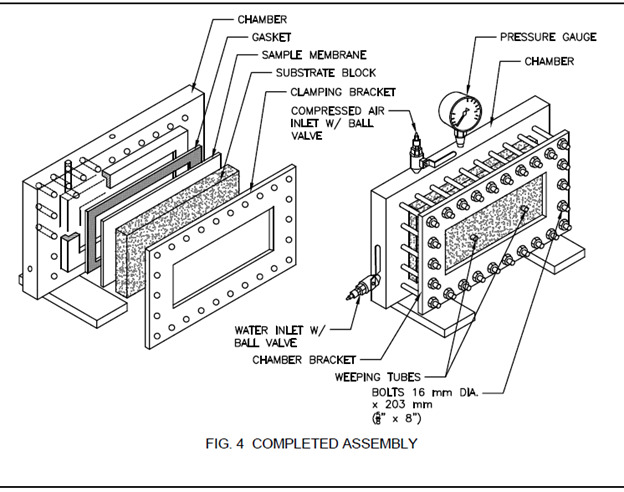

The proposed test modifies the D5385 setup but rethinks the configuration:

- Pre-applied membranes are cast with concrete to replicate blindside conditions

- A section of membrane is intentionally breached to simulate a defect

- Weep tubes are installed near the breach to detect lateral movement of water under hydrostatic pressure.

The test increases pressure gradually, up to 100 psi (231 feet of water head). A membrane’s lateral water migration resistance is reported as the maximum pressure it withstood for a minimum of one hour without water leaking from the weep tubes.

The procedure also includes detailed instructions for sample prep, concrete curing, water detection, and reporting. It’s already undergone round-robin testing and is under ballot review at ASTM.

Real-World Results from Independent Testing

A recent study by Certerra (formerly PRI Construction Materials Technologies) used the proposed method to test ten blindside waterproofing membranes. The results told a clear story about what works—and what doesn’t.

- Fully self-adhered membranes, like MiraPLY-H and Blueskin PreSeal 435, held strong at 100 psi with no leaks.

- Mechanically bonded systems, which rely more on surface texture than chemical adhesion, broke down at much lower pressures, some as low as 30 psi.

“This wasn’t a one-off,” says DiGiovanni. “The independent lab confirmed what we’ve seen in our own labs. If a membrane doesn’t form an adhesive seal to the concrete, water is going to find its way in.”

Why Verified Test Data Matters to Design Pros

Design pros are expected to balance performance, cost, and installation challenges. But without standardized test data, they’re left to interpret manufacturers’ letters, footnotes and marketing claims.

“Designers want options,” says Rowland. “But that can mean accepting products that look the same on paper, even if they behave very differently in the field.”

He suggests asking two key questions before making a membrane selection:

- How was the product tested for lateral migration resistance?

- Do you have third-party validation?

Answers should include hydrostatic pressure ratings, duration, and failure criteria, not vague references to internal methods. “A lab saying the sample passed until the machine broke isn’t a pass,” says Rowland.

“It’s about credibility,” adds DiGiovanni. “If two membranes both claim resistance to lateral migration, they should be tested the same way.”

The Long-Term Cost of Chasing Leaks

Some lower-cost membranes may seem attractive at first, but they often lead to much greater costs down the road. Mechanically bonded products, in particular, may lack the tight adhesion needed to stop water migration. Once installed behind finished walls or under floor slabs, water intrusion can cause significant damage to drywall, flooring, insulation, and even electrical systems before the leak is discovered.

“Owners have come to expect leaks as part of the package. They budget for repairs from day one for the lower-cost membranes,” says Rowland.

But membranes that prevent lateral migration are easier to inspect and repair. “When the leak lines up with the defect, you know where to look,” DiGiovanni explains. “That means faster fixes, lower leak remediation costs, and fewer disruptions.”

What’s Next: Standards That Raise the Bar

The proposed test method is currently undergoing ASTM balloting. Final adoption could still take time, but the direction is clear.

“It will change the conversation,” says Rowland. “Once a standard is in place, products that don’t pass will have to either adapt or explain why they shouldn’t be held to the same bar.”

Meanwhile, design pros can begin raising the bar on their own. Asking for lateral water migration test results, verified by a third party, is a powerful step toward clarity and confidence.

Standards Stop the Leak Chase

The job of blindside waterproofing is simple: keep water out. But for too long, the industry has lacked consistent, standardized tools to verify whether that performance is actually achieved.

By supporting the proposed lateral water migration test method, design pros can help shift the market toward specifying membranes that perform better, both in the lab and in-place behind the wall and underslab.

Because let’s face it, chasing leaks is nobody’s idea of a good time.

All information listed in this section was submitted by Henry.

Kenilworth Media Inc. cannot assume responsibility for errors of relevance,

fact or omission. The publisher does not endorse any products featured in this article.