Artistry meets practicality on a wet slab of concrete

Images courtesy Wagner Meters

Concrete mixture

The makeup of the concrete, specifically its w/c ratio, is the single largest variable determining the drying time needed before the flooring can be installed. Other concrete ingredients, such as the chemical admixtures, can also directly impact drying time. Specifying the makeup of the project’s concrete allows one to factor this into the anticipated drying time, thereby helping build realistic expectations about the total timeline.

Slab thickness

As the concrete slab dries, moisture moves within it and eventually evaporates into the air. The thicker the slab, the longer the time that must be allowed for it to sufficiently dry. While the maxim seems to be 28 to 30 days of drying time for each 25 mm (1 in.) of slab thickness, it is important to remember this is merely an approximation. Given the number of variables that can ignificantly affect drying time—ranging from w/c ratio to ambient conditions—one should never rely on this rule of thumb as a precise way for making drying time predictions. (Studies were conducted in the 1990s by Göran Hedenblad and others. A good source of information from this period is his “Drying of Construction Water in Concrete-drying Times and Moisture Measurement,” published in 1997 in Stockholm as part of the series, Protection of Buildings Against Moisture.)

Design components

It is important to decide during the planning phase how, and to what extent, additional materials and slab design elements (e.g. vapor retarders or curing blankets) will be employed. Their use impacts the drying time of the slab.

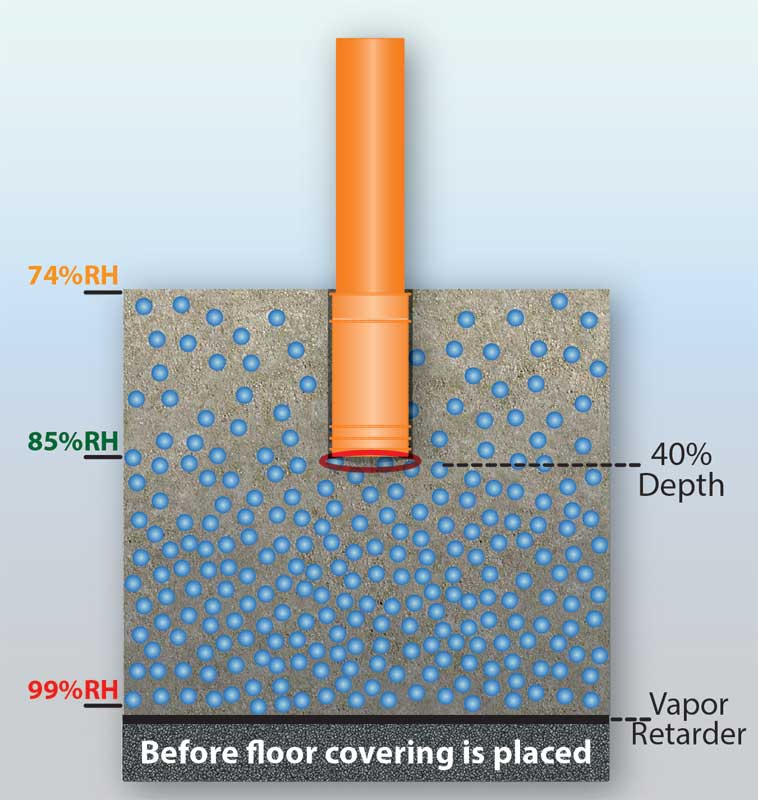

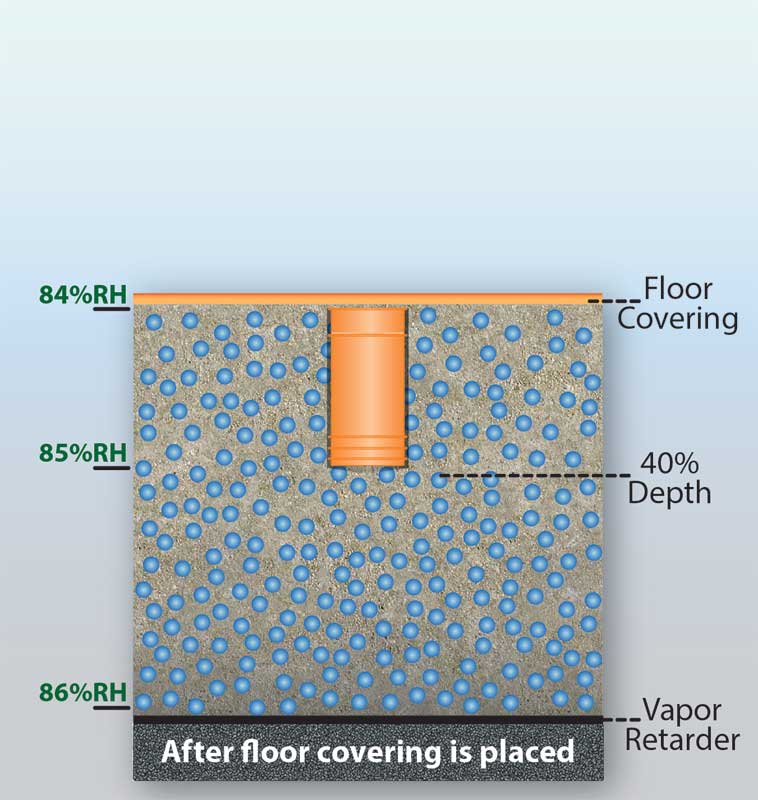

For example, vapor retarders are beneficial because they prevent the slab from absorbing groundwater. However, at the same time, their use also means the moisture already in the slab now only has one route for escape. Vapor retarders are typically considered a ‘net-positive,’ but their impact on drying time has to be considered. On the other side of the spectrum, the specification of either a curing blanket or curing compound inhibits the release of moisture vapor.

Troweling

Beautiful to behold, glossy concrete surfaces are quite popular. However, using a power trowel to get a smooth surface compresses the concrete. This reduces the slab’s porous nature and closes off naturally occurring internal routes for moisture to evaporate. When employing a lightweight concrete application, the impact is even greater. Even if not using a power trowel finish, it is very important to remember the angle of the blade during troweling changes the amount of pressure being exerted on the concrete’s surface. For these reasons, the trowel finish process should be specified and also included in the calculation of the slab’s drying time and, ultimately, in the project timeline

Ambient conditions

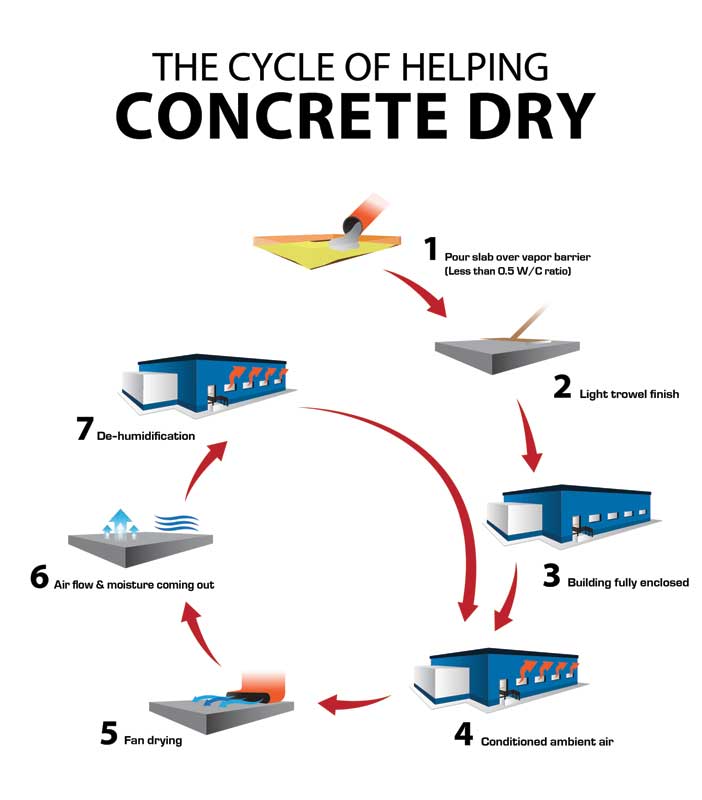

The conditions under which the concrete slab dries must not be left to chance. While a slab might be exposed to weather for a time, as soon as the building site gets enclosed, a lot can be done to control the ambient conditions. Architects and specifiers can reduce the possibility of unfavorable project outcomes caused by concrete moisture by specifying what to do in relation to such conditions. One should know what conditions are expected and control them to the best degree possible—this allows a reasonable anticipation of how much time will be needed for the slab to dry sufficiently. Several different atmospheric variables should be considered.

As mentioned, concrete dries as the moisture within it evaporates. If the air is already full of moisture, as measured by RH, it cannot draw any moisture from the concrete. If the air is greater than 85 percent RH, the slab may be absorbing moisture from the air, rather than drying. Anytime the RH in the air is higher than the RH in the slab, the concrete draws moisture out of the air instead of releasing it. Consequently, it is important to control the amount of RH in the air and know the humidity level within the concrete.

The temperature of the air affects its dewpoint, which determines how much moisture the air can hold. Cold temperatures have a lower dewpoint, so they lengthen the drying process. As such, the expected air temperature for when the concrete slab is laid and allowed to dry needs to be a known entity. Additionally, one must plan ahead and decide which tools—such as fans or dehumidifiers—might be used to impact the effects of air temperature and other ambient conditions.

Further, air that does not move may let evaporated moisture resettle on the surface of the concrete. When determining how some flow will be provided to the space, whether through fans or HVAC, it is important to remember these details also impact the other ambient conditions.