Boost building efficiency with below-grade polyiso

Achieving higher thermal efficiency with less material

Insulation is integral to enhancing both a building’s energy efficiency and the comfort of its occupants. In below-grade applications—where construction elements are beneath ground level—the selection of insulation material has great importance. Below-grade insulation protects parts of a building that are below-ground levels such as basements, foundation walls, and crawl spaces, from heat transfer and moisture.

Polyisocyanurate, commonly referred to as polyiso, is a cost-effective and sustainable option for for below-grade insulations, because of its exceptional properties and benefits. Polyiso below-grade insulation reduces environmental impact by offering a higher R-value than extruded polystyrene insulation (XPS) insulation, requiring 25 percent less material volume, 25 percent fewer truckloads, and 25 percent less storage space for the same square feet of material. Below-grade insulation demands resilience, and polyiso meets and exceeds that challenge with ease.

What is polyiso insulation?

Polyiso is a closed-cell, rigid foam board insulation with exceptional thermal efficiency and high R-value per inch of thickness. Comprised of a thermoset plastic foam core, typically sandwiched between aluminum, coated glass facers, or polyethylene terephthalate (PET) facers, it makes an optimal choice for temperature regulation in buildings.

Used primarily as exterior continuous insulation, polyiso also serves effectively for below-grade applications. Through a continuous lamination process, polyiso forms a durable, thermally resistant core with its typical facers.

Cost-effectiveness

Despite its notable properties and performance, polyiso insulation remains cost-effective, especially for below-grade applications. One of the key factors contributing to its cost-effectiveness is its inherent durability. Unlike some other insulation options, polyiso is highly resistant to moisture, mold, and pests. This resilience ensures it maintains its structural integrity and thermal performance over an extended period.

Further, polyiso’s prolonged service life significantly reduces lifecycle costs associated with insulation. With proper installation, polyiso can last for decades without degradation or loss of performance.

Environmental sustainability

The environmental footprint of building materials is an increasing concern. Polyiso distinguishes itself with a lower environmental impact compared to other insulation materials. For example, some polyisos use blowing agents with 90 percent less Global Warming Potential (GWP) than comparable next-generation XPS products.

Polyiso’s high R-value per inch enables thinner boards, which reduces material and transportation costs. Further, it incorporates durable eco-friendly facers that enhance product performance and mitigate environmental impact.

Potential misconceptions

Many architects and contractors associate polyiso with commercial roofing material, where it is regularly used. The most common facer for polyiso roof insulation is an organic paper-faced material, which can absorb water, but remains dry when contained within a roofing system. This has led to the misconception that polyiso itself absorbs water, which is not true. The foam core in polyiso, like XPS, is a closed-cell foam that does not absorb water.

When specifying polyiso for exterior walls or below grade applications, it is important to use water-resistant facers such as aluminum, PET, or coated fiberglass.

Another misperception about polyiso pertains to below grade R-value specifications. When specifying rigid below grade insulation, designers often believe they need 50.8 mm (2 in.) of thickness to achieve an R-value of 10, or 72 mm (3 in.) for an R-value of 15. However, these specifications are based on XPS.

The correct specifications for polyiso are 38 mm (1.5 in.) for an R-value of 10 and 58 mm (2.3 in.) for an R-value of 15. Since this insulation achieves a higher R-value per inch than XPS, it is critical to ensure the proper thickness is specified to meet the code requirements, which will also reduce costs and environmental impact.

High thermal efficiency

Polyiso’s key characteristic, high thermal efficiency, plays a key role in reducing energy expenses and the overall energy efficiency of structures across below-grade applications. The high R-value per inch of polyiso underscores its ability to provide high thermal insulation compared to many alternative materials.

Moisture and water resistance

In below-grade applications, moisture infiltration poses a significant threat to building integrity and effective moisture management is critical. Polyiso and XPS share similar characteristics, as both are closed-cell foams with similar water and moisture resistance properties. The key advantage of polyiso is its higher thermal performance, achieving the same results with less material, which means reduced costs and less waste.

At the core of polyiso’s water resistance is its closed-cell structure, which serves as a barrier against water absorption. This inherent resistance to water absorption ensures polyiso insulation maintains its structural integrity and insulating properties over time, regardless of the surrounding environmental conditions.

The water resistance of polyiso insulation can be further enhanced by using water-resistant facers, such as aluminum foil, PET, or coated fiberglass.

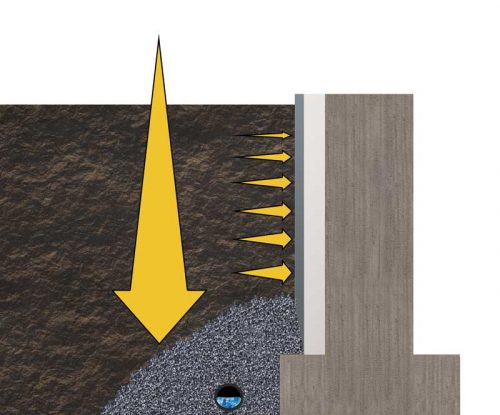

In below-grade applications, where the risk of water intrusion is particularly high, the combination of polyiso’s closed-cell structure and water-resistant facers offers high protection against moisture-related damage. Whether used in foundation walls, below-grade floors, or other below-grade assemblies, polyiso provides a reliable barrier that protects the building envelope from the detrimental effects of water infiltration.

Consistent familiar installation method

After the concrete foundation is poured, the exterior is coated with a waterproofing material such as roll-on, spray-on, or peel-and-stick applications. Polyiso below-grade insulation can then be installed similarly to XPS. The adhesive is applied and the polyiso boards attach easily, which achieves the energy code requirements. Bulldozers subsequently push the backfill in around the foundation.

In addition to meeting energy codes, below-grade insulation also protects the waterproofing layer from damage when the backfill is pushed in against the foundation. When R-10 is required, simply use a 38-mm (1.5-in.) polyiso board instead of a 50.8-mm (2-in.) XPS board; and when R-15 is required, use a 58-mm (2.3-in.) polyiso board instead of a 72-mm (3-in.) XPS board. This standardized and straightforward installation process ensures the insulation protects both the waterproofing and the building interior from external temperatures.

Increased occupant comfort

Polyiso insulation plays a crucial role against cool, damp environments in below-grade spaces, where moisture infiltration and heat loss can pose significant challenges. Through its dual action of mitigating heat transfer and thwarting moisture intrusion, it ensures interior spaces below grade remain comfortable and free from the effects of the external environment.

Proper specification

When specifying polyiso for below-grade applications, it is important to use the correct type with a non-water-absorbent facer, instead of polyiso roofing products. Additionally, it is always important to remember polyiso is more thermally efficient than XPS, so the board thickness can be reduced by 25 percent compared to XPS. Utilizing 38 mm (1.5 in.) boards for an R-10, and 58-mm (2.3-in.) boards for na R-15 will yield the optimal results.

Conclusion

Polyiso insulation presents a multitude of advantages for below-grade applications, by using 25 percent less materials resulting in lower costs. When specified at the correct thickness, polyiso is more cost-effective than XPS. This decrease in material will result in lower labor, transportation, and storage costs. Opting for polyiso guarantees heightened building performance, durability, and sustainability, allowing contractors, architects, and builders to achieve excellence across the board.

Author

James Reed has more than 27 years in the building materials industry and serves as vertical market manager for Rmax Below-Grade Insulation at Sika Rmax, a division of the Sika Corporation. Dedicated to supporting contractors and architects by providing top-tier products and solutions with a strong focus on sustainability, Reed leads efforts to equip buildings with efficient rigid foam insulation for walls and underslabs. His role focuses on advancing technologies that enhance performance and environmental stewardship.