Calculating and templating a masonry opening

Calculating the degree of skewback

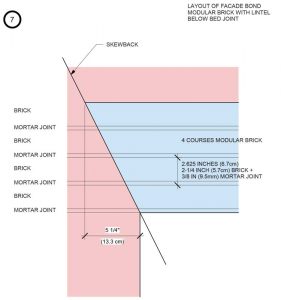

To determine the degree of skewback, one must calculate the full brick widths at the top of the extrados. In this case, one must calculate an angle which will allow a 1.2-m intrados, plus the additional length for extrados (i.e. X millimetres/inches on the left and right widths).

Knowing the rough opening is 1.2 m, the skewback needs to be less than 152 mm (6 in.) wide on each side. Jack arches seldom extend further than a brick; this is where the 60- to 70-degree skewback comes into play (Figure 2).

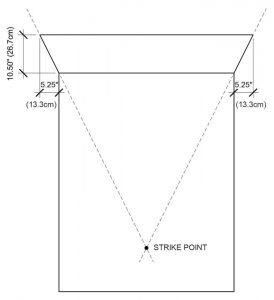

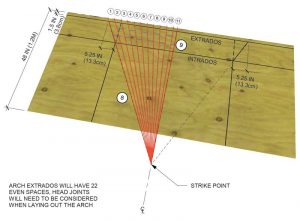

In Figure 2, by drawing the 63-degree skewback on cardboard, it was useful to see how far left and right the arch top would extend once the skewback angle was determined. The 63-degree skewback angle will add 133 mm (5.25 in.) to each side of the intrados, making the extrados 266 mm wider than the intrados.

To calculate the number of bricks in the extrados, the math is as follows:

1.2 m (rough opening) + 0.27 m = 1.46 m (4.8 ft) (opening at extrados)

1.46 m ÷ 67 mm (2.6 in.) (brick and mortar joint) = 22.3 bricks

This is perfect because it means the extrados includes 22 full-width bricks with head joints. There will be 7.3 mm (0.29 in.) for the extra mortar joint required for balancing that is 3.3 mm (0.125 in.) off which can be bonded out.

To determine the brick and mortar joint dimension at the bottom course of the arch, the following calculation is necessary:

1.2 m (rough opening) ÷ 22 brick opening (determined at the extrados or the top of the arch) = 55 mm (2.16 in.) brick and mortar joint.

After performing these calculations, the typical solution is to adjust and tighten the head joints or recalculate until a dimension for 22 bricks and 23 head joints will fit into the 1.2 m rough-opening dimension.

After performing these calculations, the typical solution is to adjust and tighten the head joints or recalculate until a dimension for 22 bricks and 23 head joints will fit into the 1.2 m rough-opening dimension.

Twenty-three head joints x 9.5 mm per head joint = 219 mm (8.63 in.), which is between 16 and 19 mm (0.625 and 0.75 in.). Therefore, in this case, one should use 219 mm for head joints. This leaves the following calculation for a 1.2 m rough opening

219 mm = 1000 mm (8.63 in. = 39.37 in.)

To calculate a more exact width for the cuts at the intrados, one should use the following formula:

1000 mm ÷ 22 bricks = 45.4 mm per brick (39.37 in. ÷ 22 bricks = 1.8 in. per brick

The benefits of a jack arch template

The benefits of a jack arch template

After one has calculated the necessary measurements, they can make a template to facilitate the brick. Using 6.4 mm (0.25 in.) plywood is helpful, as it is more durable than cardboard or poster board. It can also be easily stored if multiple arches are required for the project. When marking up the template, one should use a fine-tipped marker, as it will lead to sharp lines and keep the markings more accurate.

To make the template, a 1.2 x 2.4 m (4 x 8 ft) sheet of plywood, a set of clamps, a sturdy work surface, a straight edge, markers, a jig saw, a drill, and a 16d nail (89-mm [3.5-in.] long) are all useful, since there is a 1.2 m rough opening. Once the template has been completed, one can then turn the plywood and mark out the opening.