By Steven Fechino

Jack arches are a structural element in masonry construction that builders have used for centuries. Also known as flat or straight arches, they are structural elements that provide support at openings in masonry.

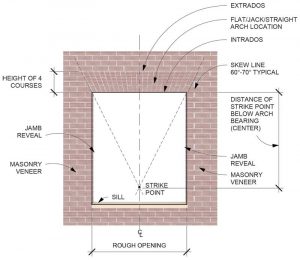

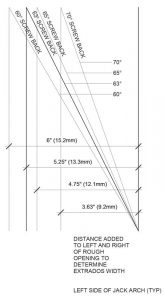

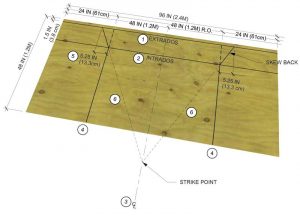

At some point, masonry contractors may need to incorporate a jack arch into their work. To calculate the cuts for a custom jack arch, a mason will need to create a cutting template. Three integral pieces of information are necessary to begin the process. First, one must know the width of the rough opening. Second, one must know how many courses vertically the arch will extend, and hence, the width of the jack arch at the extrados (top of the arch) as per the skewback. The jack arch will have full-width units at the extrados and a mason will cut these to a thinner width at the intrados (bottom of the arch or lintel location). Third, as the previous piece of information infers, one must know what angle they want the arch’s left and right ends to duplicate and how the ends will look; this is the skewback—the end voussoir (arch brick) at the extrados. Working with the degree of skewback or skew line angle can simplify the building of and material cutting for the arch (Figure 1).

One can apply this layout math for a jack arch to any size of brick they are installing.

Light commercial façade use

Figure 1 is an example of a jack arch for a small building, such as a bank or a light commercial façade.

This project requires modular brick, 9.5-mm (0.375-in.) joints, and four courses of vertical arch height. Full brick is necessary at the extrados and, with a 1.2-m (4-ft) opening, it will have full-brick widths at the top of the arch and workable cut widths at the bottom of the arch.

It is easier to build an arch with an odd number of bricks. However, in this case, an odd number will not fit properly. This means the center of the arch will be the head joint of the mid span of the arch. There will not be a key brick (or center brick) in this case. To determine the arch material, one should calculate the extrados based on the masonry rough opening, the width of each of the skewbacks added to the intrados, the dimensions of modular brick, plus one mortar joint for each brick. After determining all of this, one should add an additional mortar joint to balance the arch; this is typical of all arches.

∞ Mortar joint: 9.5 mm;

∞ Modular brick (height): 57 mm (2.25 in.); and

∞ Modular brick + mortar joint: 9.5 + 57 mm = 66.5 mm (2.625 in.).

This example uses 66.5 mm as the width of the voussoir plus a mortar joint (arch brick plus mortar joint).

The jack arch will be sitting on a lintel which will not alter the calculations but will simplify the thought process due to the façade bond. The jack arch will extend to the fourth vertical course of wall façade brick. The extrados is where the jack arch voussoirs (arch brick) extend to; for this example, look at four courses. Four courses of the façade bond (typically running bond or English bond) of modular brick plus each mortar joint will be 66.5 mm x 4 courses = 266 mm (2.625 in./course x 4 courses = 10.5 in.) above the lintel (the lintel also represents the intrados of the arch or the bottom of the arch).

The skewback angle is anywhere from 60 to 70 degrees. The greater the skewback’s angle, the farther the strike point is from the bottom of the arch. The strike point is used to pivot the skew line or vary the arch’s width, and thereby, to mark every brick for cutting. The strike point is drawn from the left and right skewback following the skewback angle to a point on a center line that defines the masonry opening. By calculating the number of bricks at the top of the arch, one can define the skewback angle. This is just one way of doing it; there are several different methods.

Please discuss thru-wall flashing and weeps when utilizing jack arches in masonry veneer construction.

BTW, the article on jack arches was quite informative and interesting. Curious about the mention of a loose lintel in the article. Other than for forming purposes, why would one bother? It introduces many other un-needed issues into the brick veneer.

The use of weeping holes in masonry is synonymous with type N mortar and modern wall systems. Older buildings being restored with the correct lime based mortar act like goretex where the water evaporates through the less dense mortar, eliminating the need for weepers.

Metric dimensions are incorrect they should be centimetres or remove the decimal point !

Yup, a standard masonry joint is 10mm.