Construction Dewatering: Understanding its effect on below-grade waterproofing

Types of dewatering

Dewatering can be either temporary or permanent. In temporary dewatering or construction dewatering, the water table is drawn down and maintained below a certain level, which is commonly determined by the project’s geotechnical engineer to be 0.9 m (3 ft) below the bottom of the excavation. The primary objective of temporary dewatering is to remove water from the site during construction activities; after which, dewatering is stopped and the original water table is restored.

Permanent dewatering, which is achieved with exclusion, pumps, or subsurface drainage, is for the life of the structure. The objective behind permanent dewatering is to maintain a water table below a certain level—primarily to reduce buoyant forces, and also secondarily to reduce the potential for leakage into below-grade areas of the building.

Site dewatering is usually achieved by controlling groundwater through exclusion (permanent) or removing it by pumping (temporary or permanent). Groundwater control by exclusion is achieved by constructing an impermeable or low permeability cut-off wall to keep the groundwater out of the excavation. Incidental water—such as rainwater, seepage, or groundwater trapped within the cut-off area—is removed by pumping. Groundwater control by pumping is achieved by allowing groundwater into the excavation and pumping it out through sumps, or by removing it through wells or well points inside the excavation or at the perimeter. Although both methods of groundwater control are effective, groundwater control by exclusion has a lower impact on groundwater levels outside the cut-off area and is often used in areas sensitive to change in groundwater levels or where there are limitations on pumping discharge.

If the water table is lowered outside the excavated portion of a project, this can result in significant settlement of compressible soil layers outside the project—especially in normally consolidated or slightly over consolidated soils, which can significantly impact adjacent utilities, roadways, and structures. (See section 3.11 of Guidelines of Engineering Practice For Braced and Tied-Back Excavations, published by ASCE in 1997).Timber piles can rapidly decay as a result of lowered groundwater. For this reason, city building authorities typically require dewatering to occur inside the footprint of the excavation and for the shoring walls to be exposed to greater direct hydrostatic pressure, creating a higher potential for the shoring wall to exhibit leakage and to require repairs as part of the preparation of the waterproofing substrate.

Excavation and shoring leakage

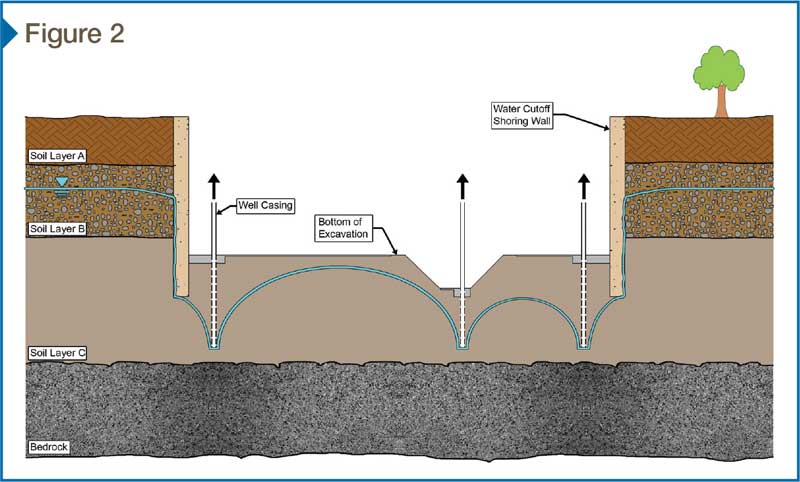

For most projects, construction dewatering drives the selection of the shoring system. Shoring systems vary in their permeability and how much groundwater they retain. The highly porous soldier beams and wood lagging shoring system (Figure 1) are on one end of the spectrum, where vertical soldier beams provide lateral stabilization to horizontally-oriented sawn lumber (i.e. lagging) inserted behind the front or back flange of the soldier beam.

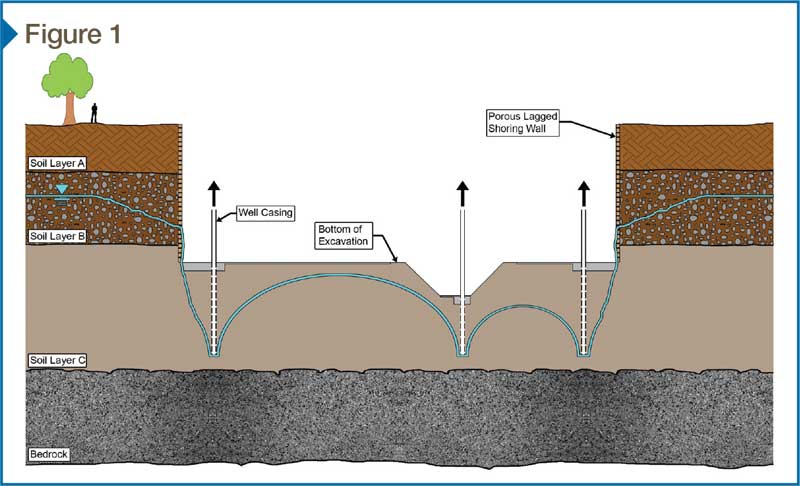

On the other side of the spectrum, there are ‘water-cutoff’ shoring systems (Figure 2), such as soil-cement mix (CSM) secant pile walls, slurry walls, and sheetpile walls—all of which may be laterally strengthened with tiebacks or lateral bracing.