For the Want of a Horseshoe Nail: Identifying causes of tile failure

Mortar selection

Several types of cementitious mortars are available to facilitate tile installation and ensure long-term performance of tiled floors or walls. They include:

- non-sag mortars for use on vertical surfaces and overhead;

- rapid-setting mortars for time-critical installations and for use with moisture-sensitive stone and agglomerate tiles;

- highly polymer-modified mortars for improved strength, adhesion, and resilience; and

- large and heavy tile (LHT) mortars for large-format tiles.

The latter category—LHT mortars—is another component of the apartment project’s failed 600 x 600-mm (24 x 24-in.) tile installation.

The TCNA handbook describes LHT mortars (formerly referred to as medium-bed mortars) as thin-set bonding mortars formulated to minimize slump and facilitate a thicker bond coat (from 3 to 13 mm [3/32 in. to 1/2 in.] thick) after the tile is embedded. LHT mortars are useful for setting:

- heavy tiles more than 2 kg/0.1 m2 (more than 5 lb/sf);

- tiles with ungauged thicknesses; and

- large tiles with at least one side greater than 380 mm (15 in.).

There are no ANSI standards for this type of mortar. However, LHT mortars must meet the requirements of existing ANSI standards for the installation of ceramic tiles, which include:

- A118.1, Specifications for Dry-set Cement;

- A118.4, Specifications for Modified Dry-set Cement;

- A118.11, Specifications for EGP (Exterior Glue Plywood) Latex-Portland Cement Mortar; and

- A118.15, Specifications for Improved Modified Dry-set Cement Mortar.

These and other tile-specific standards can be found in the TCNA publication ANSI A108, A118, and A136–American National Standard Specifications for the Installation of Ceramic Tile.

Applying a mortar too thin will likely lead to inadequate coverage, particularly if there is warpage in the tile. Lack of coverage creates voids under the tile, ultimately leading to cracking and delamination. Applying mortar too thick is also problematic. Mortars applied in excess of their formulated and functional thickness will shrink as they dry and cure. This can also create voids under the tile, and can pull the tile from the bottom as the mortar shrinks, cracking it.

A contractor may apply an excessively thick mortar bond coat if:

- the substrate was not made true with leveling or patching compounds prior to tile installation;

- the mortar is applied in spots rather than uniformly troweled; or

- the installer is utilizing a standard thin-set mortar, not an LHT mortar, for large-format tiles.

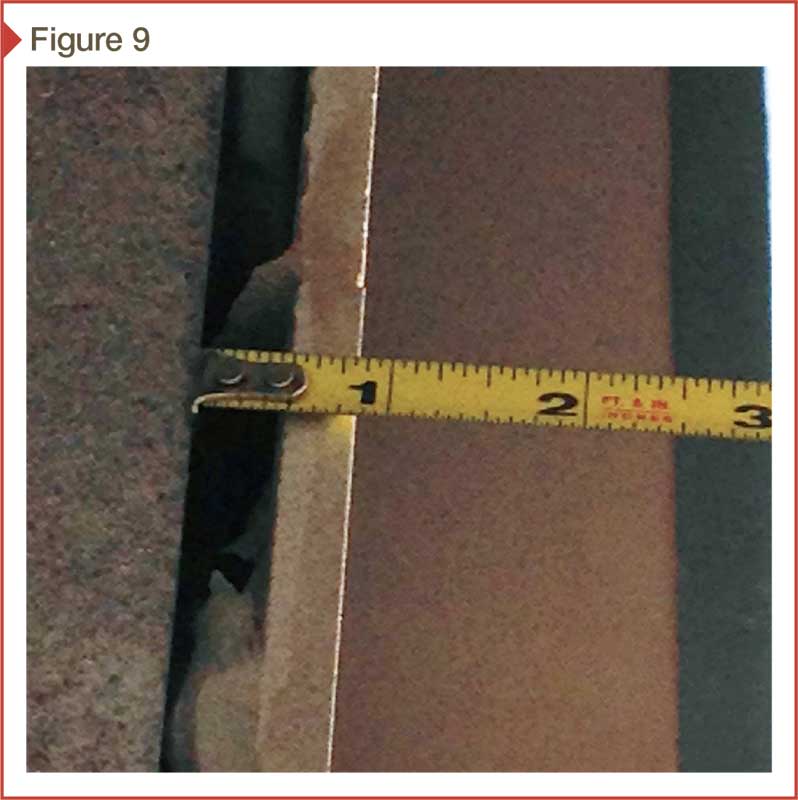

Typically, the maximum applied thickness for a standard thin-set mortar is 6 mm (1/4 in.). In the case of this project, the installer incorrectly used and over-applied this type of mortar by spot-bonding. It would have been much more effective to uniformly trowel an LHT mortar at maximum applied thickness of 13 mm (3/4 in.) before tile embedment (Figure 9).

In hindsight

Many problems are associated with this tile installation, any of which could have caused the tiles to loosen and fall eventually. The lack of movement joints and resultant water infiltration through the cracked grout joint simply accelerated this deterioration. Value engineering, installer inexperience, and fast-tracking also played a role. Perhaps the calamitous omission (i.e. the proverbial nail) was not the lack of movement joints, but failure to read, understand, and employ tile installation methods readily available and clearly stated in the TCNA handbook and ANSI standards for tile installation.

Howard Jancy, CSI, CDT, is a commercial architectural services representative for Custom Building Products. He has 30 years of experience with tile, stone, and concrete flooring, as well as paving design, installation, and remediation. Jancy’s responsibilities include specification writing and review, technical service, and continuing education. He has written articles for numerous industry publications, including Landscape Contractor National, the Journal of Architectural Coatings, and The Construction Specifier. Jancy has also been a presenter at World of Concrete (WOC). He can be reached via e-mail at hjancy@cbpmail.net.