Illustrating the Dew Point: An effective way to determine its value

Determining the R-values

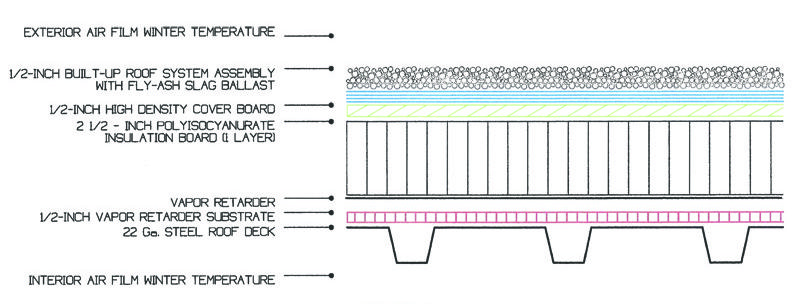

The next step involves determining the actual R-value of each individual product or material being called for in the assembly, as every building material has distinct thermal resistance properties.

Typical thermal properties of common building materials can be found in the “Moisture Control” section of NRCA’s Roofing and Waterproofing Manual or Chapter 25 (“Thermal & Water Vapor Transition Data”) of the 2001 ASHRAE Handbook–Fundamentals. Due to limitations, some of the values for individual components were obtained via multiple online searches. (Websites visited to establish R-values of various individual components include www.sizes.com, www.cmfac.groups.et.byu.net, www.coloradoenergy.org, www.courses.washington.edu, www.gpgypsum.com, www.inspectapedia.com, and www.archtoolbox.com.)

During this process, it is important to note air film exists on both the interior and exterior sides of the roof assembly. This air film has an R-value contributing to the assembly’s overall R-value. It is also important to note there are different R-values for interior and exterior air films during winter and summer months. The R-values of the individual components used in this example are:

- interior air film (winter) design temperature: 0.68;

- 22-gauge (Type B) steel roof deck: 0.00;

- HD roof vapor retarder substrate: 0.56;

- three-ply BUR vapor retarder: 0.12;

- 64-mm (2 ½-in.) polyiso rigid insulation board: 14.40;

- 12-mm (½-in.) thick HD insulation roof coverboard: 0.56;

- five-ply BUR roof system with fly-ash slag aggregate covering: 1.52; and

- outside air film (winter) design temperature: 0.17.

Arriving at the R-value of the entire construction assembly involves adding together the value of each individual component. In this case, the total R-value of the entire roof assembly is 18.01.

At this point, one must keep in mind the importance of computing the necessary mathematical calculations to avoid undesirable conditions that would support the growth of mold and mildew and/or the accumulation of unwanted moisture within the roof system assembly. However, in establishing the correct design dew point temperature, it is vital to remember several influencing factors, including:

- all indicated R-values and dew point temperatures are subject to change along with the pattern of the four seasons and local weather conditions;

- every building structure has its own unique R-value based on the geographical location and the materials used during the actual construction process; and

- improper ventilation, insufficient insulation, and improperly installed vapor retarders all impact design conditions.

One method preferred by many architects, engineers, HVAC system designers, and roof consultants to accomplish this task is to graphically illustrate a drawing of the roof system assembly being proposed. All temperatures are measured at the top side of each component, and are plotted on the drawing as closely as possible to that position, with the actual illustrations drawn in a proportion large enough to clearly display the various components (Figure 4).