Meeting ceiling requirements in restaurant settings

Strength and cleanability

Standardized tests can be used to evaluate the relative merits of various ceiling products to withstand the high demands placed on restaurant kitchens regarding hygiene, as well as the ability to withstand cleaning and the wear caused by handling tiles during cleaning procedures.

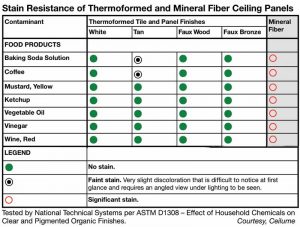

Reports on products that have been tested according to ASTM D1308, Standard Test Method for Effect of Household Chemicals on Clear and Pigmented Coating Systems, may provide some guidance on stain resistance and cleanability relative to food substances. Reagents are applied to specimen, allowed to sit, cleaned using prescribed techniques, and then visually examined (Figure 8).

Some ceiling manufacturers, unfortunately, make vague representations about the performance of their products without explaining the basis for their claims. While ASTM cautions that lab testing does not necessarily replicate field conditions, test results can be used for comparison and should be requested when considering products for which the specifier does not have firsthand experience.

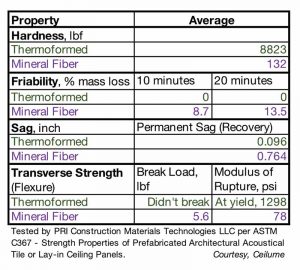

ASTM C367/C367M, Standard Test Methods for Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-in Ceiling Panels, is the ceiling industry’s recognized consensus standard for measuring four characteristics of ceiling products:

- Hardness is determined by the depth of an indentation made by a dropped weight. Greater hardness correlates to a panel’s increased resistance to impact and abuse.

- Friability measures the weight of material which erodes when specimens are placed in a rotating tumbler. Less weight loss indicates a reduced likelihood of edge damage when a panel is installed or handled during maintenance. Some friable ceiling materials are stable when intact, but when damaged may shed respirable fibers, which may include silica fiber, a hazardous material. Materials tested with greater hardness and/or lower friability reduce the likelihood of fiber shed.

- Sag resistance is determined by exposing a product to high humidity, allowing it to return to normal ambient conditions, and measuring how much permanent sag occurs. Panels with less sag indicate greater resistance

to moisture. - Transverse strength indicates a panel’s resistance to breakage from impact or being dropped.

See Figure 7 which provides an example of test results pertaining to ASTM C367/C367M.