Unlocking BHMA’s updated standards

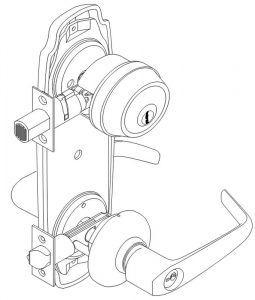

Function numbers are crucial as they are used by specifiers to pick the application needed. The function numbers in this standard cover residential to commercial settings, including passage/closet latches, hotel guest locks, and front door lock functions. There are also functions for classrooms which involve certain kinds of locking arrangement due to the unfortunate increase of school shootings. Teachers and school boards have insisted on incorporating locks that allow staff and students to lock classrooms from the inside as opposed to the outside like they typically do. Classroom security continues to grow as a concern in the building code and construction field.

ANSI/BHMA A156.24: Delayed Egress Locking Systems

A156.24 covers products used in connection with conventional exit devices or locks causing the doors to remain locked after releasing actuation for a predetermined length of time. This refers to doors that have a short delay in opening to prevent individuals, who may not be allowed to leave, from exiting the building. The delayed egress meets building code requirements, prevalent where patients and residents should not wander off. This includes facilities such as memory care wards, psychiatric and mental health units, and senior assisted living. These are also common in airports doors leading out to the tarmac, as well

as big retail stores, for anti-theft purposes and additional security.

There were important tweaks made to this standard, including a revision to the test door hinge description in 4.2 under “test methods,” stating, “Doors shall be hung on Grade 1 heavy-duty anti-friction bearing hinges or pivots.” In addition, reference standards were updated, style formatting was edited to match standard documents, and details covered in building codes were transferred out of the standard. A156.24 includes performance criteria for functional, cycle, operational, fail-safe, and overload requirements.

How do these standards affect the industry?

A good portion of these standards deals with detailed instructions on how to test and evaluate the performance of the hardware, to be followed by the test labs and manufacturers. This should be helpful to specifiers as the testing results offer a grading rank from 1 to 3. Grade 1 being the highest and suitable for the most rigorous applications, while grades 2 and 3 might be more economical choices for other lower demand installations. For example, the cycle tests are done under laboratory conditions, often with extra loads, so the exact quantities are not directly transferable to their life in actual installations, and in fact could be expected to exceed them. The standards also set industry definitions and terminology as well as detailed descriptions of the various “functions” or “types” to select for the applications (i.e. storeroom or entrance functions).

Although these changes do not directly affect architects and specifiers, BHMA standards allow for a common language between architects, specifiers, and builders to communicate about the different types and required performance levels of architectural hardware products.

BHMA is currently working on standards relating to energy consumption of electrified hardware, acoustic properties of hardware for noise sensitive applications such as hospitals, and the development of test methods for architectural hardware resistance to harsh environments.

For more than 20 years, Michael Tierney has served as the product standards director for Builders Hardware Manufacturers Association (BMHA), where he coordinated the development and revision of the BHMA performance standards for building hardware products. Tierney came to BHMA following a 20-year career in manufacturing management at United Technologies, Honeywell, Black and Decker, and Yale Security. He is a principal member on technical committees for the National Fire Protection Association (NFPA); the A117.1, Committee

For more than 20 years, Michael Tierney has served as the product standards director for Builders Hardware Manufacturers Association (BMHA), where he coordinated the development and revision of the BHMA performance standards for building hardware products. Tierney came to BHMA following a 20-year career in manufacturing management at United Technologies, Honeywell, Black and Decker, and Yale Security. He is a principal member on technical committees for the National Fire Protection Association (NFPA); the A117.1, Committee Karen Bishop has extensive technical and managerial experience in the commercial openings industry. Before joining BHMA, she served as a senior engineer for new product development, certification, and testing at the Allegion Hollow Metal Group. Bishop has held leadership roles at several associations, including Steel Door Institute (SDI) and National Association of Architectural Metal Manufacturers (NAAMM), among others.

Karen Bishop has extensive technical and managerial experience in the commercial openings industry. Before joining BHMA, she served as a senior engineer for new product development, certification, and testing at the Allegion Hollow Metal Group. Bishop has held leadership roles at several associations, including Steel Door Institute (SDI) and National Association of Architectural Metal Manufacturers (NAAMM), among others.