When Wetter May Be Wiser: Designing for resilience in areas subject to flooding

Unacceptable as flood openings are any air ventilations devices that can be manually closed (unless disabled into the open position), have detachable solid covers, or are designed to open and close based on temperature (unless also designed to allow for automatic entry and exit of floodwater). Windows, exterior doors, and garage doors are also unacceptable methods of flood venting due to the need for human intervention to open them, unless appropriate automatic flood openings are installed in them.

If water cannot flow between them, each enclosed area within the footprint of a structure is subject to the same requirements as cited above. The openings must function automatically to allow free flow of floodwaters both into and out of each enclosed area.

Non-engineered and engineered openings

Any opening allowing for automatic entry and exit of floodwaters may qualify as an appropriate flood opening. For example, simply leaving a block out of a foundation wall could be acceptable.

Communities often require screening over such openings to limit entry of insects and rodents—this may still be a serviceable flood opening if the screen does not impede water from entering and exiting, and there is no covering preventing water from entering or requiring human presence and active involvement to open or remove it. This is an example of a non-engineered flood opening.

Section 2.6.2.1 of ASCE 24 addresses the number, size, and location of non-engineered openings, primarily reiterating the previously noted requirements of 44 CFR 60.3(c)(5), but adding openings must be at least 76 mm (3 in.) in any direction in the plane of the wall. The opening may be of any shape—round, elliptical, or rectangular—but must achieve this minimum dimension in every direction to help prevent blockage by small debris and sediment.

Engineered openings fall into two categories:

- those unique and specifically designed and certified for an identified structure by the appropriate licensed design professional as meeting design and regulatory requirements; and

- those mass-manufactured and issued an Evaluation Report by the International Code Council Evaluation Service (ICC-ES).

For individually designed engineered openings, the responsible design professional must provide a certification including the individual’s name, address, signature, type of license, license number, the state in which the license was issued, and the individual’s signature and seal. Technical Bulletin 1 specifies the following information to be included in the certification:

- identification of the building in which the engineered openings will be installed;

- certifying statement addressing the automatic entry and exit of floodwaters and compliance with design requirements of Section 2.6.2.2 of ASCE 24;

- description of the range of flood characteristics tested or computed for which the certification is valid, such as rates of rise and fall of floodwaters, and

- description of the installation requirements or limitations that, if not followed, will void the certification.

ICC-ES Evaluation Reports for manufactured flood openings are issued only after a review of the performance testing results, technical design reports, and certifications (as per Technical Bulletin 1) submitted by a manufacturer. Most importantly, the engineered openings must pass ICC Acceptance Criteria (AC) for Automatic Foundation Flood Vents (AFFV) to prove they perform under flood conditions.

Design professionals may find a benefit to specifying mass-manufactured engineered openings in the ability to rely on the manufacturer’s certification. Alleviation of individual liability requires proper installation of the appropriate number of ICC-ES evaluated flood openings in the proper locations. By visiting the ICC-ES site, all manufacturer claims can be checked to ensure the products are in fact certified and listed. Testing must account for and evaluate debris clogging, automatic opening, and the opening’s size to relieve hydrostatic loads. Certified products are identifiable in the field by a label containing model number and ICC-ES-certified coverage.

Conclusion

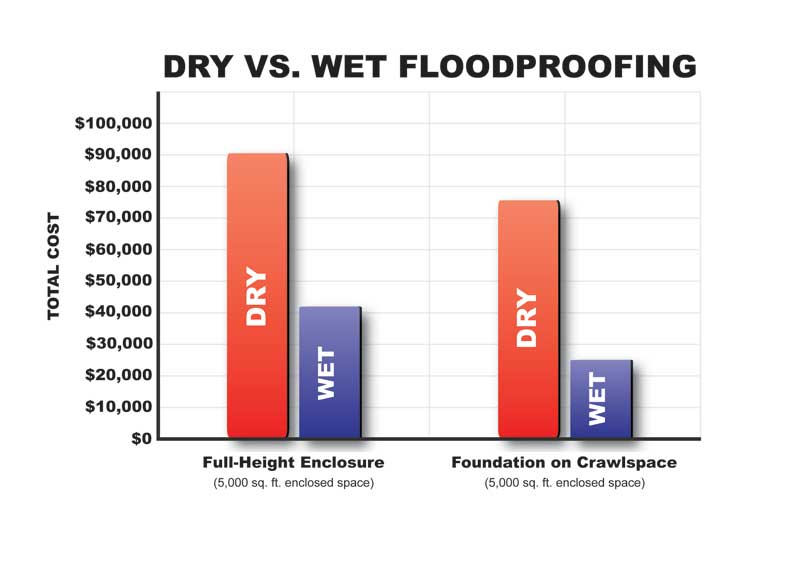

Wet floodproofing methods reduce structural stresses caused by hydrostatic pressure during flooding. When installations comply with building standards and floodplain management regulations, this approach may offer reduced construction costs and increased public safety. Engineered openings provide the additional benefit of certification regarding performance.

Tom Little, CFM, CGP, has studied the science of flood mitigation for eight years with a concentration in proper flood-venting techniques. As the vice president of Smart Vent Products, he is responsible for the education programs training architects, engineers, code officials, and other trade professionals on the importance of proper flood mitigation techniques. Little works directly with design professionals to ensure floodplain projects comply with local, state, and federal requirements. He is a Certified Floodplain Manager (CFM) through the Association of State Floodplain Managers (ASFPM). Little can be contacted via e-mail at tlittle@smartvent.com.