Where art meets infrastructure: Glass windscreens as urban storytellers

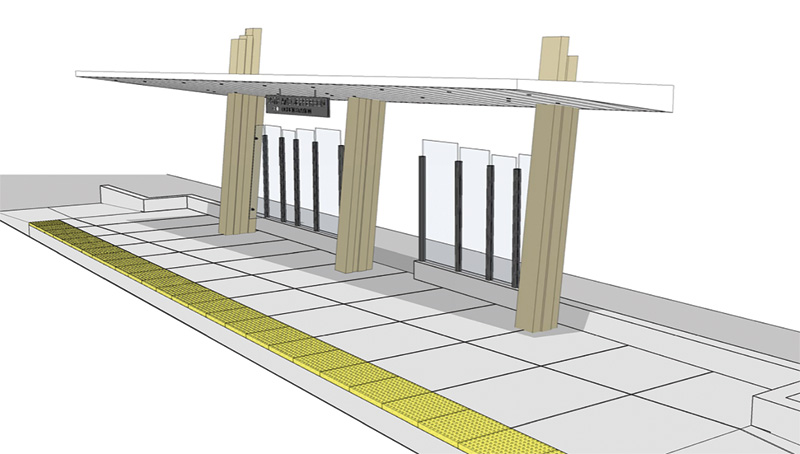

Urban transit systems are evolving to meet growing demands for sustainable, accessible, and visually engaging public transportation. As part of this evolution, thoughtfully designed infrastructure elements such as windscreens play a vital role in improving commuter experiences and fostering community pride.

In Utah, the Ogden Rapid Transit Bus is a great project example that showcases how functional requirements and artistic ambition can align in the design of laminated glass. By examining design considerations, material selection, and installation methodologies, the project serves as a model for integrating art with public transportation infrastructure.

Design considerations for transit windscreens

Windscreens in urban bus shelters serve a dual purpose: protecting commuters from environmental elements and enhancing the aesthetic character of transit spaces. The Ogden project required windscreens capable of withstanding wind, rain, snow, and UV exposure while reflecting the cultural vibrancy of the local community through integrated artwork.

A key aspect of the design intent involved creating four distinct bus station designs: Small Side, Center, Large Side, and Large Split, each tailored to its surrounding environment. Small Side stations used lower-profile windscreens to blend into residential neighborhoods, while Large Split stations employed expansive panels to serve as focal points in public spaces and on campus grounds. This variation ensured each shelter contributed to its context and reinforced a sense of place along the 21-station route.

Key design parameters included:

- Durability and safety—Laminated glass was specified to meet impact resistance and safety standards, complying with ANSI Z97.1, Safety Glazing Materials Used in Buildings, and ASTM C1048, Standard Specification for Heat-Strengthened and Fully Tempered Flat Glass, requirements for public glazing.

- Aesthetic integration—Artwork and photography from local artists were incorporated to promote community identity and visual engagement.

- Structural performance—Cantilevered panels and point-supported hardware achieved a floating glass appearance while ensuring structural integrity under dynamic loads.

- Maintenance—Choosing glass simplifies cleaning, extends the windscreen’s lifespan, and protects its aesthetic.

- Transparent material—Using architectural-grade glass to house a translucent, yet vibrant digital print invites color to a space without losing ambient light.

In addition, the shelters were designed with accessibility in mind, ensuring compliance with Americans with Disabilities Act (ADA) requirements for clearances and reach ranges.

Material selection and fabrication

The primary material selected for the windscreens was 14 mm (0.56 in.) laminated glass. This material, composed of two glass lites bonded with an adhesive interlayer, provides shatter resistance and the ability to encapsulate artwork without degradation over time. Laminated glass also delivers acoustic benefits by helping to reduce ambient traffic noise. The laminated and monolithic glass gauge was chosen to balance safety precautions and acoustic performance criteria, offering increased rigidity and sound attenuation where safety and durability within high pedestrian and vehicular activity are critical.

The laminated glass used in this application has a sound transmission class (STC) rating of approximately 38, compared to an STC of around 36 for 13 mm (0.5 in.) monolithic glass, as measured by ASTM E90. The lamination of two glass lites enhances acoustic performance by dampening sound vibrations and improving noise absorption, contributing to a quieter, more comfortable environment for occupants. The STC rating is derived from accredited lab testing and falls within the industry standard for laminated glass.

The project required 119 laminated glass panels to complete the 21 bus stations. Each panel was fabricated to precise dimensions, with sizes and configurations tailored to its designated station type.

In addition to the laminated panels, 13 mm (0.5 in.) clear float monolithic glass panels were installed as side elements. These panels, secured with point-supported hardware, minimized visual obstructions while providing lateral protection from wind and rain. Any exposed glass edges were polished for safety and aesthetic purposes.

Long-term acoustic performance of laminated glass in exterior applications

In outdoor environments, long-term acoustic integrity is often questioned due to potential environmental stressors such as UV exposure, moisture ingress, temperature fluctuations, and physical degradation. However, in-field observations indicate that when properly specified and installed, laminated glass maintains its acoustic performance reliably over time. Although glass itself is a stable, non-degrading material, the interlayer’s longevity depends on several protective factors:

- UV resistance—Modern adhesives and UV-stabilized ink prevent breakdown or discoloration, preserving visual clarity and acoustic properties. Testing per ASTM G155 has shown that these interlayers can withstand prolonged UV exposure without significant degradation.

- Edge protection—Acoustic performance may be compromised if moisture penetrates the interlayer through exposed edges. To mitigate this, edge-sealing practices, such as full perimeter framing or structural silicone glazing, are employed to protect the laminate’s bond line.

- Mechanical integrity—Structural support systems and frame seals must be maintained to prevent vibration-induced wear or delamination. Over time, degraded gaskets or shifting hardware may affect system performance more than the glass itself.

- Cleaning and maintenance—Routine cleaning with non-abrasive solutions and inspection of frame integrity are critical to maintaining optimal acoustic behavior in the long term.

Field observations and precedents

No industry data or peer-reviewed evidence indicates that UV exposure, delamination, or weathering causes measurable acoustic degradation in laminated glass panels when they are correctly installed and maintained. In fact, comparable installations with digitally printed laminated glass in exterior settings have demonstrated excellent long-term performance. After several years in service, such assemblies have remained free from visual distortion, interlayer separation, or fading, and have continued to exhibit sound transmission loss characteristics consistent with their original specifications.

Digital printing integration

Integrating digital printing into laminated glass required addressing several technical factors. To preserve the vibrancy of the commissioned artwork, high-resolution digital printing was applied between the glass lites and adhesive before lamination. This approach protected

the imagery from external wear while maintaining color fidelity and detail over extended UV exposure.

- Color accuracy—Calibration between artist proofs and digital print outputs ensured consistent results across multiple production runs.

- UV stability—UV-cured inks prevented fading, tested to ASTM G155, Standard Practice for Operating Xenon Arc Lamp Apparatus for Exposure of Materials, for accelerated weathering.

- Lamination process—Controlled temperature and pressure prevented defects such as delamination or interlayer haze.

- Quality assurance—To ensure optimal performance, the panels underwent rigorous inspections, including optical distortion testing and environmental simulation trials.

- Image flexibility—Digital printing enables designers to tailor imagery with precision, adjusting scale, color, opacity, and orientation. Designers can reinforce brands with custom logos, colors, and images or showcase local and culturally significant artwork that will stay preserved and vibrant encased in laminated glass.

Close collaboration between artists, engineers, and fabricators ensured the artistic vision was translated seamlessly into durable, high-performance glass installations.

Local artistry collaboration and integration

To further strengthen the cultural connection to the community, Ogden City Arts issued a nationwide open call for artists to contribute artwork for the 13 bus stations. Artists were to draw inspiration from local themes, including Ogden’s historical architecture, regional geology, prominent historical figures, literature, and Weber State University. Twelve artists were ultimately chosen, six of whom are based in Ogden, and were assigned a specific neighborhood to research and interpret through their design. Despite geographic diversity, the artists employed a shared visual language through color palettes and stylistic elements that reflect Ogden’s natural landscape, topography, and cultural identity. The result is a cohesive visual narrative that aims to enhance the daily experience of BRT riders while celebrating the character of the city.

Engineering and hardware solutions

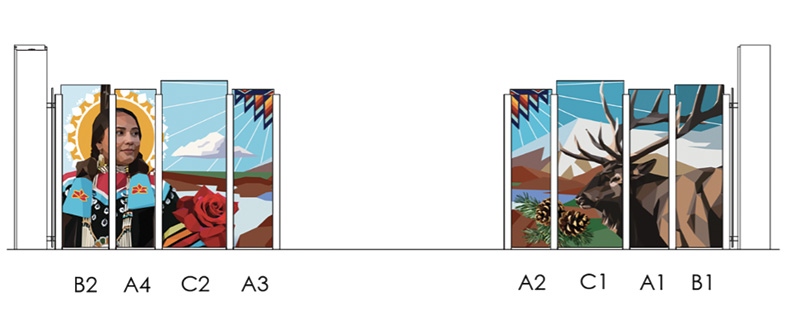

The structural system supporting the windscreens was designed to accommodate varying panel sizes and cantilevered configurations while resisting wind loads, seismic forces, and thermal expansion. Three primary panel sizes were used:

- Panel A: 488 x 1,867 mm (19 x 73 in.) with a 63 mm (2.5 in.) cantilever

- Panel B: 591 x 1,918 mm (23 x 75 in.) with a 114 mm (4 in.) cantilever

- Panel C: 794 x 1,969 mm (31 x 77 in.) with a 165 mm (6 in.) cantilever

Slotted metal framing channels and threaded rods provided primary support, enabling precise adjustments during installation. Stainless steel point-supported hardware (Spider XT joints) distributed loads evenly while achieving a minimalist aesthetic. Hardware was tested for compliance with AAMA and ASTM performance standards, including cyclic loading and corrosion resistance.

Expansion joints and neoprene gaskets allowed for thermal movement and prevented stress concentrations that could lead to cracking.

Installation process and collaboration

Installation was carefully planned to minimize traffic disruption and ensure worker safety. Certified installers and project managers:

- Used detailed templates and laser measurement tools for precise alignment.

- Pre-drilled glass panels for hardware connections, reducing field adjustments.

- Staggered installations over several months, balancing production timelines with seasonal weather considerations.

- Coordinated operations and material staging to minimize urban site disruptions.

The process underscored the importance of interdisciplinary collaboration among architects, engineers, and contractors.

Performance considerations and testing

Performance requirements addressed:

- Thermal stress—Glass thickness and interlayer composition were engineered to withstand thermal cycling without failure.

- Wind load resistance—The support system was analyzed per ASCE 7 wind load criteria.

- Impact resistance—Panels were tested to meet ANSI Z26.1 standards for hazardous glazing locations.

Additionally, the designs met snow load requirements and resisted uplift forces caused by aerodynamic effects around shelters.

Lessons learned and future applications

The Ogden windscreens illustrate how functional and aesthetic goals can harmonize in public infrastructure. Lessons include:

- Early collaboration between stakeholders minimizes rework and aligns artistic intent with technical feasibility. Clear communication with lead times and timelines is crucial.

- Digital print with UV-cured ink within laminated glass is viable for exterior use when material selection and processing are tightly controlled. Laminated glass protects from exterior elements and is optically clear.

- Modular, prefabricated designs simplify field installation and maintenance.

- Partnering with companies that offer integrated services, including engineering, hardware, materials, and installation, reduces miscommunication between contractors and specifiers, ensures comprehensive product knowledge from concept through completion, and supports more efficient, coordinated installation in the field.

- Community engagement through public art enriches user experience and strengthens civic identity.

These insights can inform future projects aiming to integrate design innovation and community values into transit infrastructure.

Innovations for resilient urban design

The design and installation of laminated glass windscreens for Ogden’s electric bus transit shelters demonstrate a successful fusion of engineering precision, artistic vision, and community-focused design. As cities increasingly prioritize sustainability and public engagement, laminated glass systems offer a durable medium for integrating art into functional spaces without compromising the longevity of the artistry it houses.

Looking ahead, emerging technologies such as dynamic shading, embedded sensors, and photovoltaic (PV) glass present new opportunities to transform transit shelters into multi-functional urban nodes. These innovations could elevate bus shelters beyond protection and aesthetics, enabling them to contribute to energy efficiency, wayfinding, and real-time data collection in urban systems. The Ogden project is a model for integrating these advancements into resilient, inspiring, and community-centered infrastructure.

Author

Aubrie Nader is a brand manager at 3form, a leading manufacturer of architectural-grade resin, glass, and acoustic materials. With more than three years of experience in B2B marketing and over a decade in creative production, she brings a strategic blend of storytelling, design knowledge, and technical expertise to the architectural materials industry. In her role, Nader leads brand messaging and campaign development to support sales teams, generate qualified leads, and drive market awareness. Her background in visual storytelling, production, and project management strengthens her ability to translate complex capabilities into compelling narratives. She is passionate about product innovation, cross-functional collaboration, and creating tools that empower designers and specifiers.

Key Takeaways

The Ogden Rapid Transit Bus project demonstrates how laminated glass windscreens can merge durability, safety, and artistry in transit shelters. Incorporating local artwork, digital printing, and structural precision, the design enhances commuter comfort, accessibility, and civic identity while showcasing resilient, sustainable strategies for integrating public art into urban infrastructure.