Beyond the forecast: The rise of weather-resistant systems

General contractors, building owners, and specifiers across the construction industry are familiar with the climate zone map. You know the one with colorful zones swooping across the country. Those colors denote regional norms, some of which include extreme heat, cold, and high moisture. However, the “Acts of God” often seen in the fine print of contracts can occur in any of these zones, at any time, disrupting construction timelines and potentially nullifying contracts. Even without the extreme weather events, environmental concerns have always been a challenge for contractors. Fortunately, building science has heard the call. Innovative products and systems are helping construction teams push past seasonal limitations and stay on track.

As weather extremes become more frequent, manufacturers are developing materials engineered to perform in unpredictable conditions. At the forefront are advanced air and water-resistive barriers (AWRBs), featuring cutting-edge chemistries such as silyl-terminated polyether (STPE) and UV-cured acrylic adhesives. These materials not only withstand winter but also enable construction to continue during this season.

Traditionally, mechanically attached building wraps served the purpose of waterproofing, but today’s air, water, and permeance requirements have led to innovation. Thanks to advances in chemistry and adhesive technologies, contractors now have a range of options that cater to various climates, substrates, and installation conditions while reducing or eliminating concerning penetrations from fasteners.

The role of AWRBs

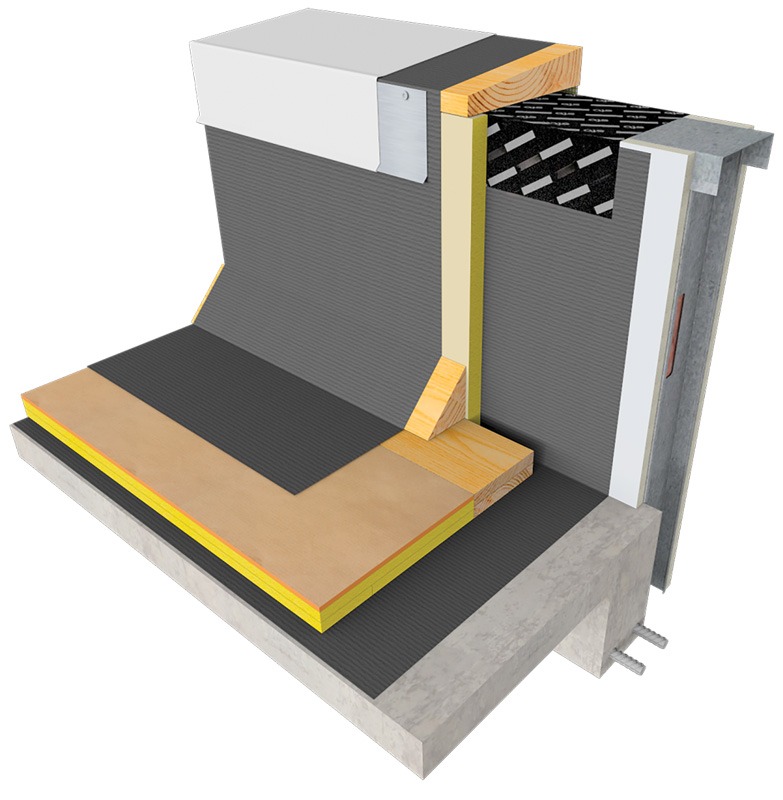

An AWRB is a protective layer that helps prevent air and water infiltration and is a critical component of the complete exterior wall system. While the term “AWRB” is commonly used in the industry to describe products that perform both functions, building codes treat air barriers and water-resistive barriers as separate requirements.

Air barriers are mandated by energy codes such as ASHRAE 90.1 and the International Energy Conservation Code (IECC) and are referenced in both the International Building Code (IBC) and International Residential Code (IRC) through their adoption of these standards. Water-resistive barriers, on the other hand, are required by the IBC and IRC to protect against bulk water intrusion in most wall assemblies. Depending on the wall system and climate zone, a project may require one or both—making it essential to select materials that satisfy multiple code requirements while also supporting long-term building performance.

Controlling air leakage through the building envelope is crucial for achieving high energy efficiency, while managing moisture is equally important for ensuring durability. The key is selecting the right product for the specific wall system and environmental conditions, but a one-size-fits-all solution does not exist. Top manufacturers offer “complete wall systems” in an effort to provide a variety of AWRB options to match system approvals and project needs. Self-adhered, roll-applied, spray-applied, trowel-applied, acrylic, hybrid, or cementitious—all have a long list of manufacturers for each category. Still, the right choice often depends on application method, system compatibility, and project budgets, in addition to the preferences of architects, building envelope specialists, and specifiers.

Seal it and keep moving

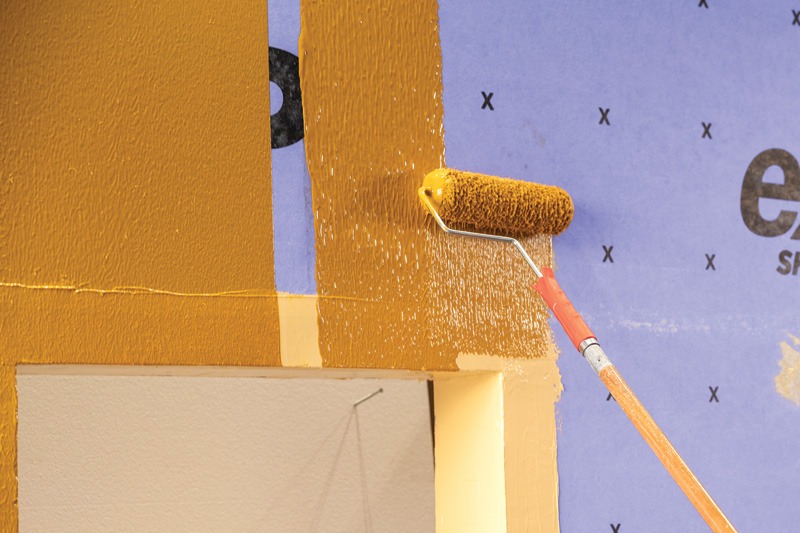

The AWRB installation serves a critical purpose in protecting the sheathing from the weather. It must be installed quickly amidst sometimes challenging environmental conditions. Leading the way in premium AWRBs are liquid-applied hybrids, such as STPE and self-adhered membranes with UV-cured acrylic adhesive. These advanced barriers enable fast installation and effective protection even in less-than-ideal conditions. Once the air and water barrier is installed, a sealed environment is created, eliminating concerns about moisture and condensation affecting materials on the job site.

Cure times and chemistry

Liquid-applied AWRBs cure through different mechanisms based on their chemistry, with the three most common being water evaporation, solvent evaporation, and chemical reaction. Water-based acrylic AWRBs cure as water evaporates from the coating, allowing the polymer particles to fuse into a continuous, protective film. Temperature, humidity, and airflow can strongly affect dry time. Solvent-based AWRBs, such as asphaltics, depend on the evaporation of carrier solvents, leaving behind a cured polymer layer. They can present challenges related to colder temperatures, substrate adhesion, odor, and VOC compliance. In contrast, reactive or moisture-cure AWRBs, such as silyl-terminated polyether systems, harden through a chemical reaction with ambient moisture, forming a more durable, crosslinked film that is less affected by adverse climate conditions. Challenges may include curing in arid climate zones and cost. Each curing method has its advantages and limitations, and understanding these differences is crucial for selecting the proper product and ensuring a successful installation.

Why is proper curing essential? Since the curing process transforms the wet material into a continuous, durable membrane that provides its intended performance. If curing is incomplete or interrupted, the barrier may stay soft, weak, or tacky, leading to less adhesion, lower water resistance, or higher risk of wash-off. Complete curing allows the material to reach its intended film thickness, continuity, and strength, which are essential for preventing bulk water penetration, stopping uncontrolled air leakage, and supporting long-term flexibility.

STPE in action

STPEs are shaping the next generation of high-performance air and water barriers. These premium, roll-on or sprayable membranes provide excellent adhesion and typically do not require priming for common substrates. STPEs have additional advantages over other products in this premium category, including ease of handling, paintability, low odor, and stable viscosity.

While water-based acrylic AWRBs remain the workhorse of the liquid-applied category, STPE delivers added versatility in challenging environments. STPE moisture-cured formulas do not rely on water evaporation to cure like other products. Where high humidity, low temperatures, and rain defeat other products, STPE thrives. STPEs can be applied in temperatures as low as -6 C (20 F). While they still require the temperature to hit 0 C (32 F) to cure, other chemistries are compromised and never cure properly when exposed to these low temperatures, regardless of how high the temperature subsequently rises. As with any AWRB, the wall system, substrate condition and type, and the environment will guide the choice.

Premium STPEs are formulated for maximum performance, often featuring wider application tolerances, greater movement accommodation, and improved environmental resistance compared to basic STPE chemistries.

Benefits of premium STPEs include:

While all STPEs offer inherent benefits, the best versions enhance these properties and provide unique benefits.

- Moisture cure chemistry—Premium STPEs cure effectively across a broader range of humidity and temperature conditions compared to standard formulas, making them ideal for cold, damp, or humid environments.

- Fast tack-free and cure times—The best formulas minimize the wait between application steps with the lowest tack and cure times.

- Low-odor, low VOC content, and isocyanate-free—A feature of most premium STPE formulations that supports indoor air quality (IAQ) standards and safe application. A tin-free formula is the pinnacle of respiratory safety in spray applications.

- Excellent adhesion to allow primer-free bonding—Bonds effectively to a wide range of substrates without additional surface treatments.

- Low dirt pick-up—Quick skin times keep jobsite applications cleaner and maintain long-term visual appeal.

- Non-sag formula—Maintains shape and coverage on vertical surfaces and in joints without running or slumping. Premium versions require a lower application thickness for performance and opacity.

- Highly resistant to moisture and weathering—Provides robust, long-lasting protection against the elements in all climates.

Adhesives breaking the cold

Innovation is not always obvious; sometimes, it is subtle and hidden in the details. Membrane adhesives, for example, continue to improve as scientists develop application-specific variants. Instead of simply using an adhesive intended for the roof, flashing tape, or below-grade applications, today’s self-adhered membranes (SAMs) are being developed to achieve excellent and targeted performance in the vertical wall space. Increasingly demanding building codes, environmental concerns, and sustainability requirements have driven innovation. UV-cured acrylic adhesive is a good example and a leading choice for SAMs in low-temperature applications, offering very aggressive adhesion and primerless compatibility with most substrates.

Most common adhesives for SAMs

Best—Acrylic. Typically comprised of acrylic or methyl acrylic polymers, these adhesives are renowned for their cohesive properties, strong adhesion, and primerless application. Three main types: UV-curable, solvent-based, and water-based.

Better—Butyl. Made of specialized, synthetic rubber, this adhesive was designed to combat the disadvantages of natural rubber adhesives.

Good—Asphaltic. Initially used in roofing applications, this cost-effective option offers good adhesion but provides a limited temperature window for application. It may require primers on many common substrates and can have limited UV exposure times.

Benefits of SAMs

- No cure time—Full adhesion is achieved once the adhesive is activated through pressure rolling. Immediate waterproofing.

- Consistent quality—Factory-controlled production ensures uniform membrane thickness and reliable performance across every roll.

- Fast installation—The peel-and-stick design simplifies application, making it ideal for large field areas and time-sensitive projects.

- Equipment-free— Eliminates the need for on-site sprayers or mixers, reducing setup time and the potential for equipment failures in cold conditions.

- Durable seams—Delivers excellent seam integrity and long-term protection against air and moisture intrusion. Many SAMs do not require pre-treat static joints and seams.

- UV and weather resistant—Withstands exposure during construction and provides lasting performance in demanding climates.

- Available in vapor-permeable or non-permeable versions—Allows design team to select the right vapor control strategy based on climate and wall assembly needs.

Additional benefits of premium SAMs with UV-cured acrylic

- Ultra-cold weather application—Can be applied and maintain adhesion at low temperatures and on damp surfaces.

- Primerless application—Strong bond to most common substrates without the need for primers, thereby reducing installation time and material costs.

- Very aggressive adhesion—Confident bond even to imperfect and porous substrates.

- Ideal for hybrid systems—Easily integrates with fluid-applied materials for a comprehensive, cold-weather-ready AWRB solution. Premium acrylic SAMs have compatibility with many liquid-applied detail components, including STPE chemistries.

Design flexibility with cold-weather barrier systems

Today’s AWRB options perform beyond compliance with performance standards—they support greater design flexibility across climates and various construction types. Both fluid-applied and self-adhered barriers are available in vapor-permeable and non-permeable formulations, allowing architects to align AWRB performance with the wall assembly’s intended drying potential.

STPE-based fluid-applied systems adapt easily to complex geometries, irregular penetrations, and dynamic joints, which are ideal for expressive facades or buildings with movement demands. Meanwhile, premium self-adhered membranes provide clean, uniform application over large field areas and simplify transitions in hybrid wall systems. With a range of adhesive chemistries, curing profiles, and compatibility-tested components, these systems give design teams the flexibility to meet both aesthetic and environmental goals without sacrificing constructability.

Total system compatibility: When materials work together

Details matter. Liquid-applied and self-adhering membrane AWRBs provide the majority of the protection. However, the compatibility of detailing components is critical to overall system integrity. Compatibility amongst products depends on factors such as material chemistry, adhesion properties, and substrate conditions. Proper integration requires careful selection of products from manufacturers who test and approve their materials for combined use, ensuring chemical compatibility and cohesive bonding. Compatibility between these materials is critical at transitions, rough openings, joints, and terminations to prevent failures that compromise performance and longevity. When compatible, a combination of liquid-applied and self-adhered components can deliver the best of both worlds. Liquid-applied components are well-suited for complex shapes, corners, and penetrations. Self-adhered membranes are particularly effective for covering large areas, quick seam work, gap bridging, and joints, especially in field conditions where substrate irregularities or misalignments may be common. Both can work synergistically, combining the flexibility and seamless coverage of liquid-applied systems with the robust, pre-engineered qualities of self-adhered membranes to create a durable and efficient wall assembly.

Testing for cold-weather AWRBs

Industry standards give everyone peace of mind. Whether developing a full-field AWRB or a detailing and flashing component, manufacturers are required to pass a significant number of tests. For cold weather, there is no single ASTM or AAMA (FGIA) standard dedicated exclusively to cold-weather applications. However, several relevant standards and guidelines address aspects such as low-temperature flexibility, adhesion, and overall durability, which are critical for AWRBs used in cold climates. Key standards and references include ASTM, AAMA, and ICC-ES. Some of the key tests that are indirectly related to cold-weather performance include:

ASTM standards

These standards test characteristics that are indirectly related to cold-weather performance:

- ASTM D1970—Standard Specification for Self-Adhering Polymer Modified Bituminous Sheet Materials Used as Steep Roofing Underlayment for Ice Dam Protection. Includes low-temperature flexibility and adhesion testing. Often referenced for cold-climate membrane performance, particularly in roofing applications, it is also relevant to wall applications.

- ASTM C1305—Standard Test Method for Crack Bridging Ability of Liquid-Applied Waterproofing Membranes. Measures a material’s ability to stretch and remain intact at low temperatures (down to -15 C [5 F] or lower). Relevant for liquid-applied AWRBs in freeze/thaw conditions.

- ASTM D903—Standard Test Method for Peel or Stripping Strength of Adhesive Bonds. Used to test the peel adhesion of self-adhered membranes. Can be modified for low-temperature conditions to evaluate cold-weather adhesion performance.

- ASTM C836/C836M—Standard Specification for High Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane for Use with Separate Wearing Course. Includes some cold-weather material performance characteristics, though not focused on vertical wall AWRBs.

- ASTM E2357—Standard Test Method for Determining Air Leakage of Air Barrier Assemblies. Measures whole-system air leakage, but not temperature-specific; however, it is often repeated after environmental conditioning, including cold.

- ASTM D3330 (tape adhesion) or ASTM D903—Some manufacturers perform modifications at subfreezing temperatures to support cold-weather use claims.

AAMA standards

- AAMA 711—Voluntary Specification for Self-Adhering Flashing Used for Installation of Exterior Wall Fenestration Products. Tests include adhesion at room and low temperatures (e.g. 18 C [0 F]). Typically used to evaluate membrane flashings used with AWRBs.

- AAMA 714—Voluntary Specification for Liquid-Applied Flashing Used to Create a Water-Resistive Seal Around Exterior Wall Openings in Buildings. Includes evaluation of durability and application in varied conditions.

ICC-ES

ICC-ES evaluation Reports, referred to as ESR reports, often include proprietary cold-weather adhesion and application temperature limits, as no mandatory standard requires all products to pass a specific cold-weather test.

In summary, manufacturers validate performance through internal testing and evaluation reports, often supplementing existing standards with cold-weather conditions. For confidence, specifiers should use trusted and reputable manufacturers and consult ICC-ES reports, technical data sheets, and project-specific mock-up testing under realistic environmental conditions.

Building without pause

The construction calendar no longer follows the seasons. With the right materials and application strategies, teams can overcome traditional limitations and keep jobs on track and on time throughout the year. Advanced AWRBs, such as STPEs and UV-cured acrylic SAMs, are more than just seasonal workarounds; they form the foundation of smarter, more resilient building envelopes.

Extreme weather may be unpredictable, but a project does not have to be.

Author

Craig Belrose is a senior product manager at Sto Corp., headquartered in Atlanta, Ga. He specializes in the StoGuard family of air and water-resistive barrier (AWRB) systems and supports the StoVentec Rainscreen Systems and Prefabricated Wall Panels business units. With more than 25 years of experience in the plastics industry and 12 years in roofing membrane development, Belrose brings deep expertise in product innovation, building envelope solutions, and materials science. His leadership helps drive advancements in high-performance, durable, and energy-efficient construction technologies.

Key Takeaways

Extreme weather challenges construction timelines, but advanced air and water-resistive barriers (AWRBs) keep projects moving year-round. Innovations such as silyl-terminated polyether (STPE-based) liquid-applied systems and UV-cured acrylic self-adhered membranes deliver strong adhesion, fast curing, and cold-weather performance. Together, they ensure durability, energy efficiency, and code compliance while enabling flexible, resilient building envelopes.