40-year study of silicone sealants: Silicone versus alternative chemistries

As structural glazing systems become more ambitious and complex, and demands for durability and sustainability continue to rise, the longevity of building materials has never been more critical.

Sealants play a crucial role in the long-term performance and weatherproofing of curtain walls and glazing systems. Choosing the right sealant can mean the difference between decades of low-maintenance performance and costly repairs and system failures.

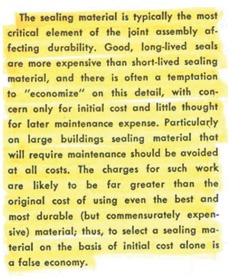

In fact, it is long been known “the sealing material is typically the most critical element of the joint assembly affecting durability,” as this excerpt from the 1966 edition of Time Saver Standards states (Figure 1).2

But which chemistry stands the test of time?

This article presents the results of one of the longest-running glazing sealant studies—a 40-year outdoor weathering assessment comparing silicone, polyurethane, and acrylic-based sealants. Conducted at the Atlas Weathering Test Site in Florida, this real-world study provides compelling insights for architects, specifiers, building envelope engineers, and contractors seeking to make informed material selections that impact every aspect of the building envelope.

The feature highlights the performance of silicone chemistries, especially acetoxy and alkoxy types, by comparing key properties such as adhesive strength, cohesive strength, flexibility, toughness, resilience, hardness, surface appearance, and long-term durability under extreme heat, UV, and humidity conditions. It also provides comparative data to inform specification decisions.

Table 1

| ID # | Polymer type, descriptors | Manuf | Filler type | Color |

| 1 | Silicone, 1PT, +/-25%, Ac | A | 100% Fumed Silica | White |

| 2 | Silicone, 1PT, +/-50%, Al | A | Calcium Carbonate / Fumed Silica | Gray |

| 3 | Silicone, 1PT, +/-50%, Al | A | Fumed Silica | Trans/Clear |

| 4 | Silicone, 1PT, +/-50%, Al | A | Calcium Carbonate / Fumed Silica | Gray |

| 5 | Silicone, 1PT, +/-50%, Al | B | Calcium Carbonate / Fumed Silica | Gray |

| 6 | Silicone, 1PT, +100/-50%, Am | B | Calcium Carbonate / Fumed Silica | Limestone |

| 7 | Silicone, 1PT, +/-25%, Ac | B | 100% Fumed Silica | Black |

| 8 | Silicone, 1PT, +/-25%, Ac | C | 100% Fumed Silica | Black |

| 9 | Silicone, 1PT, +/-25%, Ac | D | 100% Fumed Silica | Black |

| 10 | Polyurethane, 2PT, +/-50% | D | Fumed Silica | Black |

| 11 | Acrylic Terpolymer, 1PT, XX | D | Calcium Carbonate | Black |

| 12 | Polyurethane, 1PT, +/-25% | E | Calcium Carbonate / Fumed Silica | Limestone |

| 13 | Polyurethane, 1PT, +/-25% | F | Calcium Carbonate | Gray |

Description of sealant products.

The need for long-term data

Modern buildings are expected to last many decades, some for centuries. That is why it is important for modern materials to have long-term performance data under real-world conditions. While accelerated aging tests provide useful insight, nothing replaces real-world testing of the effects of outdoor exposure over extended periods.

That is why GE Silicones (now Momentive Performance Materials) launched one of the world’s most ambitious sealant weathering studies in 1983, applying a variety of sealant chemistries to test panels and leaving them exposed to Florida’s tropical climate.

The 9-ha (22-acre) Atlas Weathering Test Site (the first approved testing facility for the Cool Roof Rating Council) offered an ideal environment for the study. With high humidity, intense UV radiation, and regular tropical storms, the Florida climate is one of the most challenging natural environments for testing the durability of glazing sealants.

Key findings: A summary

After 40 years of outdoor exposure, the results are unanimous: silicone sealants consistently outperformed polyurethane and acrylic in durability, elastic recovery, and surface integrity, demonstrating long-term performance. Although the test focused on sealants, these same chemistries are used across curtain wall and glazing applications.

Study parameters

The panels used in the study featured square pieces of glass and painted aluminum substrates, mounted on outdoor racks facing south at a 45-degree angle. Thirteen sealants from six different manufacturers were applied and were evaluated at 22-, 30-, and 41-year intervals for:

- Adhesion—The sealant’s ability to bond securely with substrates over time

- Cohesion—The sealant’s ability to maintain internal integrity without splitting

- Flexibility—The material’s ability to bend and stretch without cracking

- Resilience—Measured by recovery to the original shape after being bent 180 degrees and released

- Hardness and toughness—Indicators of strength and resistance to environmental stress

- Surface appearance—Visual assessment of discoloration, cracking, and degradation

Description of sealants

All sealants used in this study were commercially available in 1983 and intended for use in construction applications. The products were sourced from six different manufacturers. As of the time this paper was prepared, nine of the original 13 sealants remained available on the market. Table 1 (page 7) below offers a brief overview of the products included in the study.

Note:

- 1PT = single-component product

- 2PT = multi-component product

- ±25, ±50, +100/50 percent = the manufacturer’s published movement capability

- Ac = acetoxy chemistry; sealant releases acetic acid during cure

- Al = alcohol chemistry; sealant releases an alcohol during cure

- Am = acetoamide chemistry; sealant releases N-ethylacetamide during cure

- XX = unknown/not published

Evaluation methods

Surface appearance and condition—The aged sealants were visually inspected for overall appearance and surface damage, such as cracking, bubbling, discoloration, dirt pickup, and other irregularities. These observations were recorded during the inspection. To help assess the sealant surfaces more clearly, light cleaning was done using a household detergent and a sponge to scrub the sealant beads

and nearby glass or metal panels. The test assemblies were cleaned and photographed both before and after sealant cleaning and removal, allowing for the best visual evaluation of the sealant surfaces.

Table 2

| ID # | Polymer type, descriptors | Overall | Dirt-pickup | Surface irregularity | Discoloration |

| 1 | Silicone, 1PT, +/-25%, Ac | Excellent | Significant | None | None |

| 2 | Silicone, 1PT, +/-50%, Al | Good | Significant | Moderate | None |

| 3 | Silicone, 1PT, +/-50%, Al | Excellent | Significant | None | Significant |

| 4 | Silicone, 1PT, +/-50%, Al | Excellent | Significant | None | None |

| 5 | Silicone, 1PT, +/-50%, Al | Excellent | Significant | None | None |

| 6 | Silicone, 1PT, +/-100/-50%, Am | Good | Significant | Moderate | Significant |

| 7 | Silicone, 1PT, +/-25%, Ac | Good | Significant | Moderate | Significant |

| 8 | Silicone, 1PT, +/-25%, Ac | Excellent | Significant | None | None |

| 9 | Silicone, 1PT, +/-25%, Ac | Excellent | Significant | None | Moderate |

| 10 | Polyurethane, 2PT, +/-50% | Poor | Light | Significant | N/A |

| 11 | Acrylic Terpolymer, 1PT, XX | Poor | Light | Significant | None |

| 12 | Polyurethane, 1PT, +/-25% | Poor | Light | Significant | Significant |

| 13 | Polyurethane, 1PT, +/-25% | Poor | Significant | Moderate | None |

Surface appearance and conditions.

Table 2 provides a qualitative assessment of the physical appearance and condition of the sealants. The following ratings were assigned and are tabulated:

- For overall surface appearance and condition—Samples were visually and qualitatively assessed as excellent, good, or poor.

- For dirt-pickup—Samples were visually and qualitatively assessed as: light, moderate,

or significant. - For surface irregularity—Samples were visually and qualitatively assessed as: none, moderate, or significant.

- For discoloration or color change—Samples were visually and qualitatively assessed as: none, moderate, or significant.

General overall condition

Table 3

| ID # | Polymer type, descriptors | Flexibility | Resilience | Toughness |

| 1 | Silicone, 1PT, +/-25%, Ac | Excellent | Excellent | Excellent |

| 2 | Silicone, 1PT, +/-50%, Al | Poor | Poor | Poor |

| 3 | Silicone, 1PT, +/-50%, Al | Excellent | Excellent | Good |

| 4 | Silicone, 1PT, +/-50%, Al | Poor | Poor | Excellent |

| 5 | Silicone, 1PT, +/-50%, Al | Good | Good | Poor |

| 6 | Silicone, 1PT, +100/-50%, Am | Excellent | Excellent | Poor |

| 7 | Silicone, 1PT, +/-25%, Ac | Excellent | Excellent | Excellent |

| 8 | Silicone, 1PT, +/-25%, Ac | Excellent | Excellent | Excellent |

| 9 | Silicone, 1PT, +/-25%, Ac | Excellent | Excellent | Excellent |

| 10 | Polyurethane, 2PT, +/-50% | Good | Poor | Poor |

| 11 | Acrylic Terpolymer, 1PT, XX | Poor | Poor | Excellent |

| 12 | Polyurethane, 1PT, +/-25% | Poor | Poor | Excellent |

| 13 | Polyurethane, 1PT, +/-25% | Poor | Poor | Excellent |

General overall condition.

The 40-year study also evaluated the sealants for flexibility, resilience, and toughness. Samples were tested using various methods, including stretching, bending, twisting, and gouging. Each sample was rated as excellent, good, or poor, with results shown in Table 3. The following definitions were used as a guide for scoring:

- Flexible—Capable of being easily bent, without breaking or cracking

- Resilience—The ability to return to the original form, position, etc., after being bent or stretched

- Toughness—Not easily gouged or defaced

Adhesion

Table 4

| ID # | Polymer type, descriptors | Adhesion check | Flexibility | Elastic recovery | |

| Glass | Aluminum | ||||

| 1 | Silicone, 1PT, +/-25%, Ac | Adhesive | Cohesive | Excellent | Yes, 100% |

| 2 | Silicone, 1PT, +/-50%, Al | Cohesive | Cohesive | Poor | N/A |

| 3 | Silicone, 1PT, +/-50%, Al | N/A | Cohesive | Excellent | Yes, 100% |

| 4 | Silicone, 1PT, +/-50%, Al | Cohesive | N/A | Poor | N/A |

| 5 | Silicone, 1PT, +/-50%, Al | 50% Cohesive | Cohesive | Poor | N/A |

| 6 | Silicone, 1PT, +100/-50%, Am | Cohesive | Cohesive | Excellent | Yes, 90% |

| 7 | Silicone, 1PT, +/-25%, Ac | N/A | Cohesive | Excellent | Yes, 100% |

| 8 | Silicone, 1PT, +/-25%, Ac | N/A | Cohesive | Excellent | Yes, 100% |

| 9 | Silicone, 1PT, +/-25%, Ac | Adhesive | Cohesive | Excellent | Yes, 100% |

| 10 | Polyurethane, 2PT, +/-50% | N/A | N/A | N/A | N/A |

| 11 | Acrylic Terpolymer, 1PT, XX | Adhesive | Cohesive | Poor | N/A |

| 12 | Polyurethane, 1PT, +/-25% | N/A | Adhesive | Good | N/A |

| 13 | Polyurethane, 1PT, +/-25% | N/A | Adhesive | Poor | N/A |

Adhesion, flexibility, and elastic recovery.

Sections of each sealant were cut from the glass and aluminum panel test assemblies, and adhesion was evaluated at that time. This was achieved through a hand-pull and visual inspection of the joint bond line to determine the mode of failure (cohesive or adhesive). Adhesion results are shown in Table 4.

Flexibility

Sections of each sealant were cut from the glass and aluminum panel test assemblies. To qualitatively assess flexibility and/or elasticity, the samples were manually bent 180 degrees, photographed, and their flexibility was noted. The results of this 180-degree bend test are shown in Table 4 and rated as excellent, good, or poor, defined as follows:

- Excellent—Sealant able to withstand an 180-degree bend without breaking or cracking

- Good—Sealant able to withstand an 180-degree bend, but with some cracking

- Poor—Sealant unable to withstand an 180-degree bend without breaking

Elastic recovery

After each sealant was manually bent 180 degrees, it was immediately released, and its elastic recovery was observed and photographed. Elastic recovery is defined as the percentage of return to its original shape within five minutes of being released from the 180-degree bend. The results are shown in Table 4. Sealants that broke during the bend test could not be evaluated for elastic recovery and are marked as N/A in Table 4.

Hardness

Table 5

| ID # | Polymer type, descriptors | Initial published hardness | 40-year hardness readings | % Change |

| 1 | Silicone, 1PT, +/-25%, Ac | 35 | 38 | 9% |

| 2 | Silicone, 1PT, +/-50%, Al | 22 | 75 | 242% |

| 3 | Silicone, 1PT, +/-50%, Al | 22 | 33 | 50% |

| 4 | Silicone, 1PT, +/-50%, Al | 22 | 67 | 205% |

| 5 | Silicone, 1PT, +/-50%, Al | 30 | 66 | 120% |

| 6 | Silicone, 1PT, +100/-50%, Am | 15 | 12 | -20% |

| 7 | Silicone, 1PT, +/-25%, Ac | 25 | 31 | 25% |

| 8 | Silicone, 1PT, +/-25%, Ac | 30 | 31 | 3% |

| 9 | Silicone, 1PT, +/-25%, Ac | 24 | 30 | 25% |

| 10 | Polyurethane, 2PT, +/-50% | 20-40 | 11 | -62% |

| 11 | Acrylic Terpolymer, 1PT, XX | 40-50 | 94 | 110% |

| 12 | Polyurethane, 1PT, +/-25% | 35-45 | 87 | 118% |

| 13 | Polyurethane, 1PT, +/-25% | 38 | 79 | 108% |

Hardness.

As before, sections of each sealant were cut from the glass and aluminum panel test assemblies. These samples were taken to the lab and tested for Type A hardness using a sealant hardness tester made by Fowler, Canton, MA. For each sample, at least three immediate readings were taken and recorded. Table 5 shows the average hardness values.

Overall durability ranking

Table 6

| ID # | Polymer type, descriptors | Flexibility | Resilience | Toughness | Change in hardness | Adhesive bond durability | Rating totals |

| 1 | Silicone, 1PT, +/-25%, Ac | 3 | 3 | 3 | 3 | 3 | Σ = 15 |

| 2 | Silicone, 1PT, +/-50%, Al | 1 | 1 | 1 | 1 | 3 | Σ = 7 |

| 3 | Silicone, 1PT, +/-50%, Al | 3 | 3 | 2 | 2 | 3 | Σ = 13 |

| 4 | Silicone, 1PT, +/-50%, Al | 1 | 1 | 3 | 1 | 3 | Σ = 9 |

| 5 | Silicone, 1PT, +/-50%, Al | 1 | 2 | 1 | 1 | 3 | Σ = 8 |

| 6 | Silicone, 1PT, +100/-50%, Am | 3 | 3 | 1 | 2 | 3 | Σ = 12 |

| 7 | Silicone, 1PT, +/-25%, Ac | 3 | 3 | 3 | 3 | 3 | Σ = 15 |

| 8 | Silicone, 1PT, +/-25%, Ac | 3 | 3 | 3 | 3 | 3 | Σ = 15 |

| 9 | Silicone, 1PT, +/-25%, Ac | 3 | 3 | 3 | 3 | 3 | Σ = 15 |

| 10 | Polyurethane, 2PT, +/-50% | 2 | 1 | 1 | 1 | 1 | Σ = 6 |

| 11 | Acrylic Terpolymer, 1PT, XX | 1 | 1 | 3 | 1 | 3 | Σ = 9 |

| 12 | Polyurethane, 1PT, +/-25% | 2 | 1 | 3 | 1 | 1 | Σ = 8 |

| 13 | Polyurethane, 1PT, +/-25% | 1 | 1 | 3 | 1 | 1 | Σ = 7 |

Overall durability ranking.

| Property | Acetoxy silicone | Alkoxy silicone | Polyurethane | Acrylic |

| Adhesion retention | Excellent | Very good | Poor | Poor |

| Elastic recovery | Excellent (100 percent) |

Excellent (100 percent) |

Moderate | Low |

| Surface appearance | Very good | Good | Fair | Poor |

| Flexibility (initial) | Moderate | Excellent | Moderate | Low |

| Flexibility (40 years) | High | Moderate | Low | Very low |

| Substrate compatibility | Limited | Broad | Moderate | Moderate |

Performance comparison of silicone versus alternative chemistries over 40 years.

A specific ranking method was used in the 40-year test to help measure the overall durability of the sealants. Only performance factors that affect weathering durability were considered; visual appearance and surface-level conditions were not included. The key properties needed for long-term outdoor use in building construction include flexibility, resilience (elastic recovery), toughness, resistance to hardness changes, and the ability to maintain long-term adhesive bonding (as shown on painted aluminum in this study). Table 6 presents the overall durability performance rankings of the evaluated sealants.

For ranking, the following rating system is used for Table 6:

- For flexibility (ref Table 4) →Excellent = 3, Good = 2, Poor = 1

- For resilience (ref Table 3) →Excellent = 3, Good = 2, Poor = 1

- For toughness (ref Table 3) →Excellent = 3, Good = 2, Poor = 1

- For percent change in hardness (ref Table 5) →0–33 = 3, 34–66 = 2, > 66 = 1

- Ability to bond for 40 years (based on results of painted aluminum test assemblies) (ref Table 4) →Adhesive

Failure = 1, Partial adhesion = 2, Cohesive failure = 3

Key findings: Silicone versus polyurethane and acrylic

After 40 years of continuous outdoor exposure, the results clearly demonstrate that silicone-based sealants outperformed polyurethane and acrylic in nearly every performance category.

- Durability—In all cases but one, silicone sealants demonstrated greater resistance to environmental aging and maintained adhesion and flexibility significantly longer.

- Elastic recovery—Silicone products displayed near-instantaneous 100 percent elastic recovery after stress, a critical factor in withstanding building movement.

- Surface condition—Silicone sealants retained a cleaner, more intact surface appearance than alternative chemistries, which exhibited more cracking and discoloration.

This level of performance makes a strong case for the benefits of silicone sealants for weatherproofing applications where longevity and structural integrity are paramount.

Acetoxy versus alkoxy: A chemistry comparison

Silicone sealants can be divided into several types, with acetoxy and alkoxy representing two of the most widely used chemistries. Each offers distinct performance profiles:

- Acetoxy silicones—These release acetic acid during curing, which limits their use on some substrates due to potential corrosion. However, they demonstrated the best long-term performance at the Florida test site, exhibiting minimal surface degradation.

- Alkoxy silicones—These release methanol during curing, a neutral, non-corrosive byproduct, that makes them suitable for a broader range of substrates, including metals such as zinc and nickel. Alkoxy silicones were found to be twice as flexible as acetoxy silicones for up to 30 years. Although their long-term durability slightly declined compared to acetoxy silicones afterwards, they still significantly outperformed polyurethane and acrylic alternatives.

Adhesion versus cohesion: Understanding failure mechanisms

One key finding from the study is the importance of understanding how sealants fail. In structural glazing and curtain wall applications, adhesion failure, where the sealant separates from the substrate, can result in catastrophic water intrusion or panel failure. Conversely, cohesive failure, where the failure occurs within the sealant itself, indicates that the bond to the substrate is still intact.

Silicone sealants consistently exhibited stronger adhesive properties than cohesive ones, reducing the risk of debonding and ensuring greater structural security.

Sustainability and cost implications

The study confirms silicone sealants value over time, with reduced maintenance, repair, and replacement costs translating into significant lifecycle savings. Moreover, silicone sealants can contribute to sustainability goals by reducing material waste and extending the lifecycles of building envelopes.

Neutral-cure alkoxy silicones also offer low volatile organic compounds (VOCs) and performance properties that help to improve indoor air quality and support sustainability certifications (such as LEED).

Future-proofing specifications

As curtain wall and glazing systems evolve to incorporate larger glass panels with higher wind load resistance and more sophisticated anchoring systems, the demands on sealants will continue to grow. Silicone’s proven long-term elasticity, UV resistance, and environmental stability make it well-suited to support the evolving design goals of super and mega-tall structures worldwide.

For building envelope engineers and specifiers, incorporating performance data from this 40-year study offers a science-backed framework for choosing materials that reduce risk and enhance performance.

Conclusion: Silicone as the standard

This 40-year study presents a compelling case for specifying and using silicone sealants in various glass applications. The combination of flexibility, adhesion retention, surface stability, and chemical safety is unmatched by polyurethane or acrylic alternatives.

Architects, specifiers, and engineers seeking to build high-performance, low-maintenance structures are continuing to consider silicone-based chemistries as a strategic investment in the building’s long-term success.

Test disclaimer

Performance results will vary depending on several process-related factors. Prospective customers should rely solely upon their own evaluative techniques to determine what processing parameters are attainable and optimal to their specific needs.

Notes

2 Callender, John Hancock. Time-saver Standards: A Handbook of Architectural Design. United States: McGraw-Hill, 1966.

Author

Errol Bull, P.E., CSI, is an application development leader at Momentive Performance Materials Inc. Member: CSI, IIBEC, ASTM C24, ISO TC59/SC8. With more than 25 years of global experience in construction sealants, adhesives, and coatings, Bull is an expert in structural glazing and sealant performance. He holds a bachelor of science in architectural engineering and a master of science in civil engineering.

Key Takeaways

A 40-year real-world study shows silicone sealants outperform polyurethane and acrylic in durability, elasticity, and surface integrity. Acetoxy excels in long-term stability; alkoxy offers broader substrate compatibility. Silicone ensures lower maintenance, cost savings, and sustainable building performance.