From mix to fix: The benefits of single-component grout

By Howard Jancy

Single-component grouts, which do not require the addition of water or epoxy resins at the job site, have evolved significantly over the years. The latest product formulations, now backed by industry-accepted standards, offer a host of benefits for both project owners and installation contractors.

A significant development for single-component grout is the introduction of dedicated ANSI standard designations: ANSI A118.19, Organic Premixed Grouts for Installation of Ceramic Tile and ANSI A108.22, Installation of Premixed Grout in Tilework. This standardization underscores the advancements in the product, ensuring quality and reliability in every application. The standards are applicable for tiles defined by ANSI A137.1, Specifications for Ceramic Tile; ANSI A137.2, Specifications for Glass Tile; and ANSI A137.3, Specifications for Gauged Porcelain Tile and Gauged Porcelain Tile Panels/Slabs.

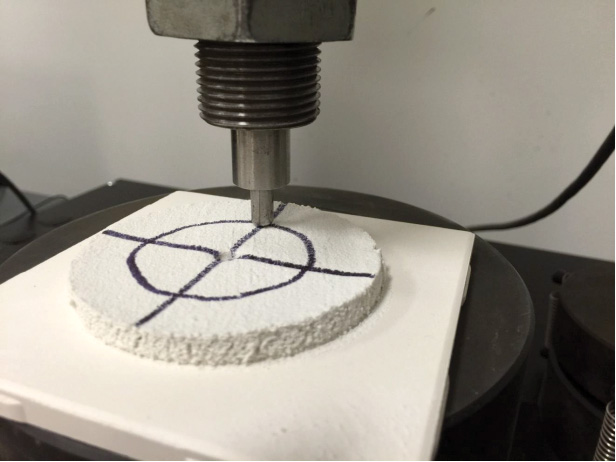

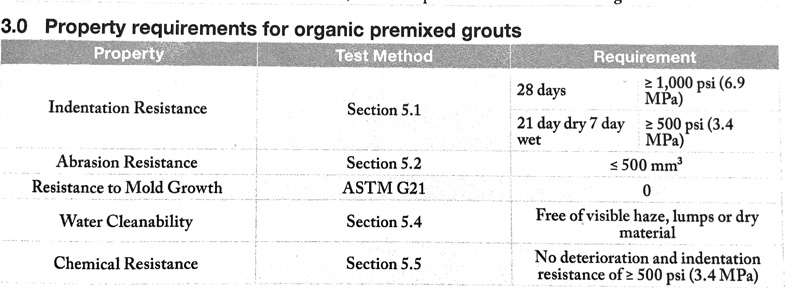

Since the formulations of this type of grout vary between manufacturers and cement and epoxy grout formulations, developing the ANSI A118.19 material standard required new test methods. For example, testing methods for indentation resistance were deemed more relevant than compressive strength since grout joints have become much smaller and would rarely see a direct point load at 3 mm (0.11 in.) (Figure 1). The new standards followed extensive testing by the Materials & Methods Standards Association (MMSA) and review and acceptance by the American National Standards Institute (ANSI) (Figure 2).

What is premixed grout?

ANSI A118.19 defines organic premixed grout “as a ready for use, factory prepared mixture of water, polymers, aggregates, pigments and other materials to produce water resistant, stain resistant, and uniformly colored materials.” Delving into the product’s definition helps one better understand what makes this type of grout a standout material.

Premixed, ready-to-use, factory prepared

All the grout’s chemical components are accurately measured and blended during manufacturing. No additional water or resinous material is added prior to installation, ensuring color uniformity and long-term durability that could otherwise be compromised by the improper mixing of water or resins on the job.

Polymers

Polymers play a crucial role in grout composition by forming a strong adhesive bond between the organic filler and pigment components and the tiles’ edges. This enhances crack and abrasion resistance and boosts water and stain resistance. Another great advantage of the polymers in single-component premixed grouts is the elimination of efflorescence, as they do not use portland cement as a binder in their formulation.

Water-resistant and stain-resistant

Single-component grouts never require a sealer. The adhesive polymer fills very small voids between the organic filler and pigments, creating an impenetrable film on the grout’s surface. Lacking open pores, the cured grout is easier to clean, and mold and bacterial growth within the grout are eliminated. Some single-component grouts even exceed epoxy grout’s stain resistance to common stains (Figure 3).

Considering its many attributes, a single-component, premixed organic grout seems to eliminate the need for cementitious and epoxy grouts. The term “organic” is often associated with mastics, and single-component grouts share some general similarities with them. These grouts can offer several potential benefits: improved indoor air quality due to lower VOCs, a safer option for installers who are allergic to epoxy-based products, and easier maintenance since they are more resistant to staining. One grout product can now be used on all residential and commercial tile installations, but can a grout choice be this simple? Unfortunately, not.

While the simplicity of choosing a single-grout product is appealing, it is crucial to evaluate additional factors before reaching a decision. Factors such as the costs of material, installation, maintenance requirements, heat and chemical resistance, and the aesthetic and functional longevity of the grout play a significant role in determining the most suitable option for a project.

The grout’s price should never be the sole determinant when selecting a product. By considering these aspects, one can make an informed decision that aligns with the project’s budget and performance requirements and the project owner’s vision.

Standards

For a better understanding of tile setting methods and materials, ANSI A108, A118, and A136, Standard Specifications for the Installation of Ceramic Tile and the TCNA Handbook for Ceramic, Glass and Stone Tile Installation should be in everyone’s technical library. There are several necessary ANSI standards for tile grouts.

The specification, ANSI A108.10, Installation of Grout in Tilework, describes the minimum requirements for grouting ceramic, porcelain, glass, and natural stone tile. It is currently under review for revision. Some of the pending revisions will better define the grouting requirements of large-format tiles, particularly large rectangular formats exhibiting warpages and installed with offset grout joints, as well as the different performance characteristics of each grout type.

ANSI A118, Material Specifications, lists four types or formulations of grout available for residential and commercial installations. Listed from the lowest to highest cost and overall performance:

- A118.6 Standard Cement Grouts—Portland cement binder plus redispersible dry

powder polymer - A118.7 High Performance Cement Grouts—Calcium-aluminate cement binder plus redispersible dry powder polymer content

- A118.19 Organic Premixed Grouts—Liquid latex polymer binder

- A118.3 Chemical Resistant—Epoxy resin binder

Inexpensive grouts are available, saving money at installation. Still, additional costs may accrue for the project owner once the tiled surface is in service, such as regular maintenance, repair, and even replacement. Let’s briefly compare the pros and cons of each grout type. For a more detailed product comparison, it is important to read the manufacturers’ technical data sheet for product performance, ANSI standard designations, limitations, and installation instructions.

ANSI 118.6—Standard Cement Grouts for Tile Installation

- Will effloresce (Figure 4)

- Lowest flexural and compressive strengths and stain resistance

- Requires a sealer and periodic reapplication to protect from staining

- Potential for moisture-related color variation: mixing, haze/residue cleaning, humidity

- Sanded grout is likely to scratch polished stone tiles: limestone, travertine, marble

- A redispersible dry polymer (RDP) added during product manufacturing eliminates errors associated with the job site addition of a liquid polymer. RDP also modifies the flow and spread of cement grouts, making them easier to apply.

- Least expensive grout formulation

ANSI A118.7—Standard Specifications for High Performance Cement Grouts for Tile Installation

- Rapid setting: elevated temperatures during mixing and installation are potentially problematic

- Less likely to effloresce

- Less likely to scratch polished stone, but a test area is recommended

- High early strength

- An RDP added during product manufacturing eliminates errors associated with the job site addition of a liquid polymer. RDP also modifies the flow and spread of cement grouts, making them easier to apply

- Improved stain resistance: higher polymer content compared to A118.6 grouts

- More color uniformity with different tile types, as well as with varying temperatures and humidity during installation and curing

- Rapid setting: less potential for sagging while curing in vertical joints during

ANSI A118.19—Standard Specifications for Organic Pre-mixed Grouts for Installation of Ceramic Tile

- Not for use in continuously submerged installations, steam rooms, or steam showers with temperatures above 71 C (160 F)

- Low temperatures or excessive moisture following installation will inhibit polymer reaction and drying, causing staining of porous natural stone and cement tiles

- Less likely to scratch polished stone, but a test area is recommended

- Crack resistant, but do not use in movement joints or at changes in plane

- Ready to use from the pail, easy to spread and clean (Figure 5)

- Will not effloresce

- Less product waste: opened pails can be resealed for later use

- No sealer required: water, stain, mold, and bacteria resistant

ANSI A118.3—Standard Specifications for Chemical Resistant, Water Cleanable Tile-Setting and -Grouting Epoxy and Water Cleanable Tile-Setting Epoxy Adhesive

- Highest material and installation cost

- Pot life and working time impacted by elevated temperatures

- Low ambient and slab temperatures delay curing and negatively affect workability

- Less UV stable

- May be allergenic to some installers

- Very specific mixing and installation requirements

- Less likely to scratch polished stone, but a test area is recommended

- Enzymatic cleaner-resistant formulations available

- No sealer required: water, stain, mold, and bacteria resistant

- High heat, abrasion, and chemical resistance

Importance of polymer technology in grouts

Polymers have been used in various construction products for many years. They have become a key component in natural stone and porcelain tile setting materials since advancements in polymer technology provide stronger and more durable installations, particularly in response to thermal cycling, continuous moisture exposure, heavy impact, and static and dynamic loads.

To understand how polymers function, consider the metal links of a chain. Each link may be strong, yet its actual benefit is derived only when connected with other links. As these links are joined, their collective strength and utility surpass those of the chain’s individual components.

Polymers are compounds formed by linking a monomer into repetitive chains. This bonding process (polymerization) creates an improved microstructure that retains and enhances the original monomer’s characteristics. When used as a binder in tile grouts, the improved characteristics are bond strength, adhesion, impact resistance, and moisture and chemical resistance.

Cement grouts without a polymer only form a mechanical bond between the aggregate and pigments and the tiles’ edges. When a polymer is used with cement grouts conforming to ANSI standards A118.6 and A118.7, the micropores typically present in the hardened cement paste and any microcracks are filled. The strengthened cement matrix contributes to the improved characteristics previously listed.

Polymers play a significant role in the formulation and performance of organic premixed grout conforming to ANSIA118.19, as the polymer is the only binder; no cement is used. As such, two of the negatives associated with cement-based construction products, the porosity of the cured material and adding too much or too little water during jobsite mixing, are eliminated. Porosity impacts water and stain resistance. Mis-mixing the water can affect workability, durability, and color uniformity.

No water or polymer is added at the job site. Once opened, the pail of grout can be used immediately without mixing. The polymer binds the mineral filler and pigments and provides an adhesive bond to the tiles’ edges.

The polymer improves the rheologic properties, flow, and spread, making grout installation easier and quicker. Instead of angular sand, a rounded organic filler enhances the grout’s flow and spread. The spherical organic filler acts like ‘ball bearings’ that provide less resistance to the contractor’s grout float and ensure that narrow grout joints are filled completely without voids.

Even the next day after installation, grout haze cleanup is easier than cement grout, particularly epoxy grout. When properly resealed and stored, a partially used pail can be used again days, weeks, or months later. Color uniformity is assured from pail to pail since the grout’s components are properly proportioned during manufacturing, and no additional liquid materials (e.g. water, polymer, epoxy) are required. Once the grout is completely cured, it is impervious to moisture and stains. It does not need a sealer, and periodic cleaning of the grout joints is quicker and easier since there are no pores to absorb and retain dirt (Figure 6).

Tile grouting, then and now

The development of each grout type shown above has been influenced by industry and project-specific needs. A low-cost, simple sand and cement grout evolved to polymer-based cement formulas due to the need for color consistency and longer working time. With the popularity of stain-resistant porcelain tiles, high-performance grout with greater stain resistance was developed to achieve lower absorption and even better color consistency. Epoxy-based grouts were difficult to use, so formula improvements expanded their use to residential and light commercial projects. With the creation of enzyme-based degreasers, typically used in commercial kitchens, new epoxy formulas were developed to be more compatible with this “no rinse” cleaning method.

Single-component grouts were created to address industry concerns regarding mistakes (too little or too much water) when mixing cement grout, efflorescence, and the need for stain resistance without sealing. Another benefit of using polymers is better resistance to cracking. So, while single-component grouts are higher priced than cement grouts, they are much lower in material and installation costs than epoxy grouts and combine some of the benefits of both.

Welcome the contemporary age of grouting solutions by choosing a premixed grout—an efficient choice for installers and a satisfying option for project owners across various projects.

Author

Howard Jancy, CSI, CDT, is the commercial architectural services representative for CUSTOM Building Products. He has more than 30 years’ experience with tile, stone and concrete flooring design, installation and remediation. His responsibilities include specification writing and review, technical services and continuing education. Jancy’s article, “For the Want of a Horseshoe Nail: Identifying Causes of Tile Failure” received The Construction Specifier’s Article of the Year Award in 2017. Jancy’s expertise includes CSI Division 03, 04, 07, 09 products and processes. He works with the contractor, distributor, designer, specifier and owner through all project phases. He understands the complexities and capabilities of a building product’s attributes to meet the architect’s requirements and the owner’s vision.

Key Takeaways

Single-component, premixed grouts have advanced significantly, following ANSI standards such as A118.19 for organic premixed grouts. These grouts are ready-to-use, eliminating the need for onsite mixing, offering enhanced durability, stain and water resistance, and mold prevention. Key features include improved crack resistance and no efflorescence. While they are more expensive than cement grouts, they offer cost savings in maintenance and installation compared to epoxy grouts. Choosing the right grout requires considering cost, installation, and long-term performance, with polymers playing a crucial role in improving grout strength, adhesion, and moisture resistance.