Designing Effective Insulation: Gravity, thermal bridging, and the importance of being continuous

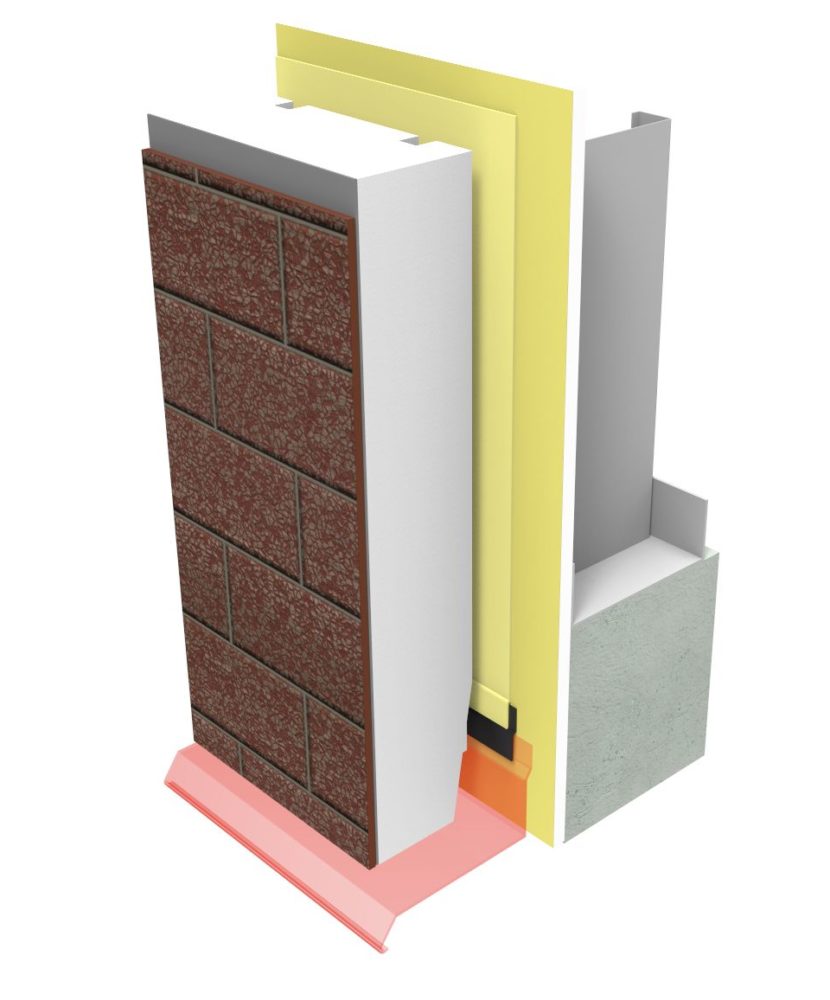

EIFS offer an alternative method of construction with a number of thermal advantages over the brick veneer wall with regard to this specific criterion. Since EIFS is adhesively fastened, there is no thermal bridging by fasteners. EIFS is also self-supporting, so there is no requirement for structural support to carry the dead load.

The intrinsic advantage of EIFS is it provides great thermal efficiency without the mass and with thinner wall dimensions. The assembly illustrated in Figure 6 with 100 mm (4 in.) of insulation and R-12 batts in the cavity will have an effective R-value of 24.6 Greater thicknesses of insulation are possible to meet requirements in colder zones.

However, EIFS also have limitations that must be taken into account. For example, EIFS wall assemblies are drained from the sheathing to the exterior. (It is important to note the Morrison Hershfield calculations for the EIFS clear wall included a geometrically defined drainage cavity (GDDC).) As with brick, a through cladding flashing is installed to drain penetrating moisture to the exterior (Figure 6). Good construction practice recommends the flashing drain beyond the cladding below. Both methods of construction would benefit from thermally broken flashing.

The Morrison Hershfield study done for the EIFS Council of Canada points out that terminations at windows should be carefully considered. The position of windows in the wall and how they align with the EIFS insulation can affect the assembly’s overall performance. Detailing the window inbound of the insulation, supported on the wall framing, has a linear transmittance of 0.35 W/m•K. Wrapping the rough opening with insulation or moving the window so the thermal break is in alignment with the insulation will make a significant performance improvement to 0.2 W/m•K.

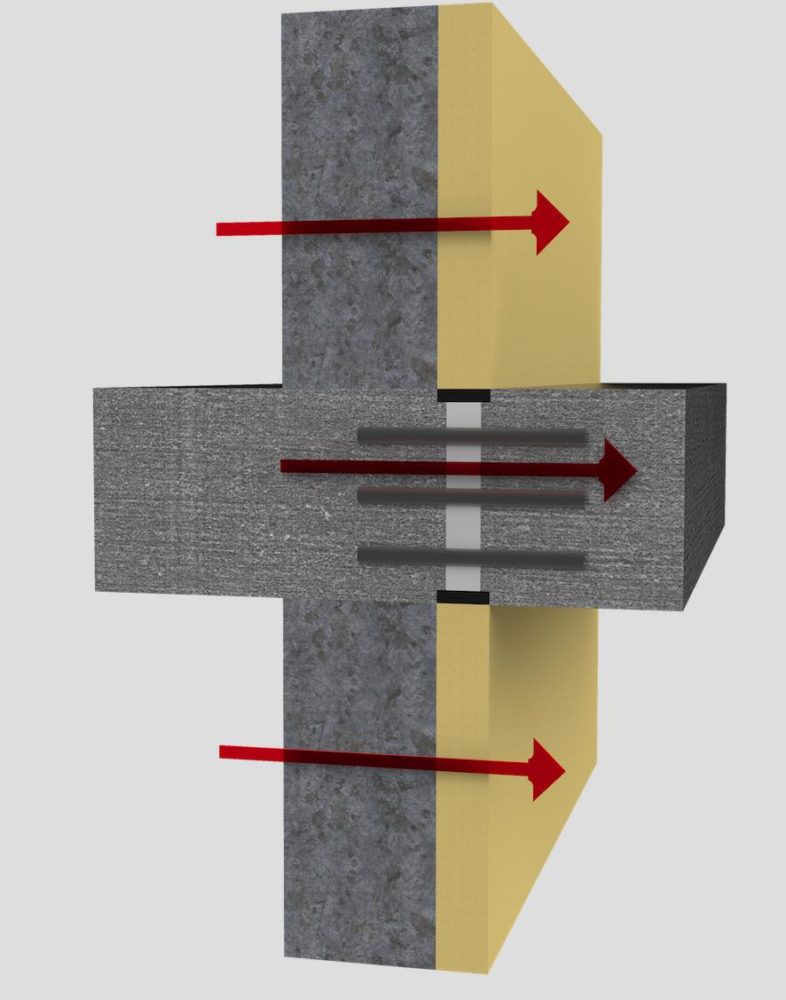

EIFS terminated at a cantilevered concrete deck will not stop the heat loss through the slab. Adding thermal breaks in the slab aligned with the insulation will have an impact on the wall performance, as was shown in Figure 5. The report shows the linear transmittance improvement from an uninsulated floor slab (i.e. 1.0 W/m•K) to one with a thermal break (i.e. 0.35 W/m•K) is significant. This would be true for all claddings.

Implementation

Just as advances in computer modeling now allow a more complete understanding of building science details, so, too, the advancing computer analysis of global warming trends continue to clarify the big picture. As data accumulates, the question of “What’s happening?” is being answered with greater accuracy, and the questions “What can we do?” and “What must we do?” are beginning to merge.

Late last year, 175 countries signed the Paris Agreement, committing to take action on climate change. Keeping global temperature rise below 1.5 C (2.7 F) was accepted as “an aspirational goal.” This is a stretch, but how does the industry get there?

In the world of energy consumption, buildings are a leading energy-user. To meet international commitments to reduce greenhouse gas (GHG) emissions, the focus must be on the built environment. Effective continuous insulation, working hand-in-hand with air leakage reduction, is the primary building prerequisite. (Airtight construction is a code requirement, and necessary for any insulated wall to function as designed. The information in this article assumes airtight construction.) This will produce the best energy reduction for the most effective cost. When the envelope is tight and insulated, other building systems may be addressed.