Failures: Curious case of floating concrete masonry unit

At a residential high-rise, staff reported concrete masonry cracking and water infiltration on the top floor of the parking garage during rain. Upon inspection, a continuous horizontal crack, up to 14.3 mm (0.5625 in.) wide, was found near the top of the concrete masonry unit (CMU) exterior wall, extending almost the entire length of one facade. The crack generally followed a masonry bed joint just below the top, revealed daylight, confirming it extended through the full thickness of the wall. A detailed investigation was undertaken to determine why the top masonry course was suspended in the air above its intended means of gravity support.

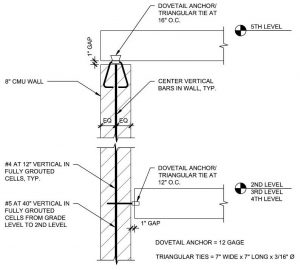

The parking garage exterior wall, a single-wythe of 203.2 mm (8 in.) CMU masonry, extends continuously from grade to the top of the fourth floor. This corresponds to the parking podium of the building, with residential floors above. Vertical reinforcing bars at 1,016 mm (40 in.) on center in grouted cells were found through a metal detector survey, revealing that they terminated one or two courses short of the top of the wall.

While the parking garage exterior wall is designed for gravity load support from grade, it is anchored to the concrete structure for lateral loads. Dovetail triangular ties, at intermediate floor slabs, anchored to the slab edge are set into a bed joint at 406.4 mm (16 in.) on center. However, at the top floor, the exterior wall abuts the underside of the fifth-floor slab, with dovetail triangular ties extending into the CMU wall below at each head joint, at 406.4 mm (16 in.) on center. The gap between the masonry and the concrete slab was filled with sealant on both faces.

At parking garage ground level, the CMU masonry is supported on a shallow footing, independent of the building’s deep foundations. Slight settlement of this footing, though minor and within expected limits for proper design, allowed the wall to move downward in relation to the adjacent building frame.

The dovetail anchors at intermediate floors allow for some vertical movement while providing lateral support. However, the wall’s top connections do not accommodate this vertical differential movement between the CMU wall and the building frame. In addition, unlike most of the wall, the top one or two courses of the CMU wall are ungrouted and unreinforced, creating a weak point where cumulative stresses from unaccommodated vertical movement led to the cracking observed. Consequently, the lateral anchors started to function as suspension anchors for the top CMU courses.

Beyond compromising the CMU wall’s structural integrity, the cracking allows air and water infiltration. The failure stems from improper use of a typical lateral anchor. Triangular dovetail ties, suitable horizontally, are not intended for vertical orientation. Instead, an anchor allowing vertical movement, such as a surface-mounted clip angle or sleeved dowel, should have been used. In addition to providing such an anchorage, restoration of the CMU wall along the crack and sealing of the top gap are recommended to protect against air and water infiltration.

Kenneth Itle, AIA, is an architect and associate principal with Wiss, Janney, Elstner Associates (WJE) in Northbrook, Ill., specializing in historic preservation. He can be reached at

kitle@wje.com.

Kenneth Itle, AIA, is an architect and associate principal with Wiss, Janney, Elstner Associates (WJE) in Northbrook, Ill., specializing in historic preservation. He can be reached at

kitle@wje.com.

Andi Mele, PE (IL), is a professional engineer and senior associate with Wiss, Janney, Elstner Associates (WJE) in Northbrook, Ill., specializing in building enclosure design. He can be reached at amele@wje.com.

Andi Mele, PE (IL), is a professional engineer and senior associate with Wiss, Janney, Elstner Associates (WJE) in Northbrook, Ill., specializing in building enclosure design. He can be reached at amele@wje.com.

The opinions expressed in Failures are based on the authors’ experiences and do not necessarily reflect that of The Construction Specifier or CSI.