Durable

A floor material needs to be able to withstand wear, pressure, and damage—concrete can do all this, but only if done correctly. All floor materials will eventually show signs of wear given an extensive amount of traffic, but a hard and dense surface is essential to keeping this minimal. When the top surface of concrete is densified by way of microscopic crystallization, the upper portion of the slab becomes extremely hard and abrasion-resistant. Sealers or other temporary topical finishes are very soft, and will scratch and wear away quite easily.

Maintainable

Densification of the surface also contributes to concrete’s ability to reject dirt and liquids. Produced correctly, concrete is inherently resistant to contaminants. What stays on the surface is easily removed. Spills that do not have a chance to get into the pores beneath the surface do not get the chance to become permanent.

Therefore, routine maintenance becomes much easier and more likely to occur regularly. Rather than create slabs needing constant reapplication of coatings or sealers that mitigate moisture and vapor transmission, one should design a slab that performs so the requirements for the material and labor are reduced.

Slip-resistant

While the expectation may be a smooth surface is slippery, this is not necessarily the case—both Occupational Safety and Health Administration (OSHA) and National Safety Council (NSC) list uneven walking surfaces as a bigger cause of trip hazards. Further, a refined concrete surface without sealers, waxes, and cleaning surfactants provides

a safe dynamic coefficient of friction (DCOF). With the growing numbers of baby boomers reaching retirement, it is critically important design/construction professionals raise the standards for both flatness and levelness.

Sustainable

As a result of the combined characteristics mentioned in the preceding sections, a concrete slab designed to keep out moisture will provide a very long-lasting flooring solution requiring minimal maintenance to keep its natural beauty throughout the entire life cycle of the facility (Figure 4). If in case the floor ever does become covered with some other surface-applied finish, it has a much better chance of recovery when the applied flooring has worn out and needs to be removed.

An added benefit of concrete that naturally maintains its volume is its natural moisture mitigation attributes. This is a huge cost saving advantage where there will be installation of moisture-sensitive floorcoverings such as tile, carpet, or epoxy coatings.

Images courtesy Tao Group

Resilient

In the past, the industry has counted on coatings, sealers, and epoxies to keep moisture in a slab. However, it is possible to create concrete naturally exceeding ASTM E96, Standard Test Methods for Water Vapor Transmission of Materials, and ASTM C309, Standard Specification for Liquid Membrane-forming Compounds for Curing Concrete. This can be achieved through use of nano-infused cements, hydro-cements, and other similar technologies that mimic ancient Roman concrete in performance, but without the long cure times.

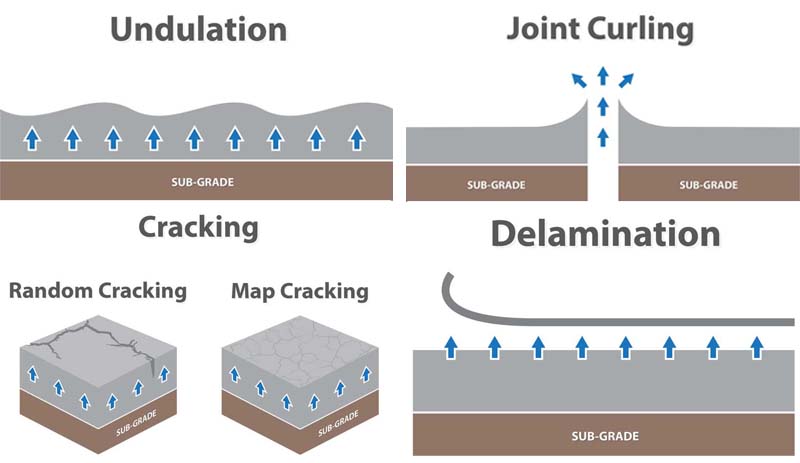

By controlling volume loss, both structural and aesthetic concrete problems diminish over the lifetime of the facility. In Bill Gate’s Fortune review of Robert Gordon’s The Rise and Fall of American Growth, he talks about new “super cement” that will allow us to “build infrastructure that lasts 10 times as long as the cement rebar approach.” Nano-infused cements, hydro-cements, and other similar based technologies are fundamental elements of this technology; it also diminishes unwanted elements such as curling, floor undulation, cracking, and slab discoloration.

This is a very interesting article. I came across it on a linked-in post. I would like to make a few comments in regards to this:

A. The standards that you talk about in regards testing for results of a polished floor seem to entirely different than the ones proposed by Concrete Polishing Council (part of the American Society of Concrete Contractors). Maybe their needs to be some collaboration to really discuss which is the better way to specify and test for results.

B. I have attended a seminar at the World of Concrete that talked about the slab being the canvas that the concrete polisher uses. It went into the details of a concrete slab from mix design to placing techniques as it relates to polishing. I would recommend it to anyone who wants more in depth knowledge on the subject.

C. Where we see the most problems in concrete slabs on grade is incompetence in production of the specifications and managing the owners expectations. Concrete slabs today are too often being specified by engineers or architects and built by contractors who have little or no experience in that realm of SOG construction. They don’t understand that their are experts who understand the behavior of slabs on grade and what is required to deliver a quality slab. Today the use of nano-silica, high dosed macro synthetic fibers, and/or steel fibers, and other admixtures along with placing and finishing technology changes the entire behavior of slabs on grade. This is compounded when the finished surface is going to be a polished slab (especially a decorative slab).