by Josh Brown

Safety statistics are a dramatic way to get people’s attention to help them understand the connection between a facility’s safety efforts, loading dock equipment (in this case, the doors), and return on investment (ROI) when specifying equipment for a project.

Recent studies by the U.S. Bureau of Labor Statistics (BLS) such as, OS NR 11/07/2013 News Release: Workplace Injuries and Illnesses–2012, noted there are almost three million work-related injuries and illnesses recorded annually. Of those, a large percentage of all recordable injuries result from slip-and-fall hazard injuries that can cost companies several billions of dollars per year.1

An example of the easiest way to avoid slips and falls in a warehouse facility is by trying to eliminate and control the hazards. Many of these can be avoided by specifying the proper loading dock doors.

Workplace injuries

The 2007 Liberty Mutual Workplace Safety Index indicates falls were the second leading cause of all workplace injuries—with 13.6 percent of direct costs associated with such injuries adding up to a staggering $6 billion. Additionally, the National Safety Council (NSC) estimates workers’ compensation and medical costs associated with employee slip-and-fall accidents are approximately $70 billion annually, and there is little relief in sight.

Loss of productivity is often a side effect of worker injury. On average, workers who are injured as a result of a slip-and-fall accident spend more days away from work than those hurt by other causes.

When considering workplace falls, most people immediately think of falls from a height, yet, the BLS suggests the vast majority (i.e. 65 percent) occur as a result of falls from same-level surfaces. Moreover, there are industries of particular interest when it comes to determining the allocation percentages for these injuries. These include warehouse, wholesale/retail, and manufacturing industries that together accounted for the greatest proportion of injuries resulting from same-level falls—more than 60 percent.

Safety standards

Safety in warehouses and manufacturing facilities is regulated by a series of standards developed by the Occupational Safety and Health Administration (OSHA). The main focus is to prevent work-related injuries and illnesses through continuous monitoring and inspections of facilities and modifications to these standards.

Loading dock locations are an important area to consider when specifying safe materials in a warehouse. There can be up to hundreds of doorways along the typical loading dock; these openings can permit moisture to enter the area to mix with dirt, debris, and oil, creating a dangerously slick surface.

Many companies are realizing warehouse safety begins with planning and prevention on the dock and inside the warehouse during the design, construction, or retrofitting of a facility. With this in mind, there is no better place to start than with the warehouse doors separating the inside of the facility and employees, from a host of potential hazards.

Dock doors can be damaged by forklift traffic and products on tight, busy docks as workers try to maneuver materials into and out of trailers. Impactable dock doors can prevent gaps from forming between the door panels when they are hit, and reduce the amount of elements and moisture that can enter a facility.

Wet floor surfaces

A particular area of concern regarding slip-and-fall injuries are wet floor surfaces. Under OSHA 29 CFR 1910.22(a)(2), Walking-Working Surfaces, the floor of every workroom should be maintained in a clean and, so far as possible, dry condition. Where wet processes are used, drainage shall be maintained, and false floors, platforms, mats, or other dry standing places should be provided where practicable.

Impactable design dock doors allow them to stand up to the abuse experienced on the dock. When a forklift or other object collides with the door, the impact causes the plungers to retract, allowing the door to release from the opening, thus preventing panel damage. After the door is knocked out from the track, a light pull on the door handles resets the door, putting it back in operation quickly without damage. This keeps the floors dry and safe, and ensures clients remain in compliance.

Since door and track damage are some of the leading causes of broken seals and gaps on doors that can cause moisture to build up on the warehouse floor, many impactable models also feature an impactable track. These tracks can run the entire length of the door opening to protect against potential damage from impacts from forklifts, masts, and materials without sustaining any damage or exposing the facility to gaps that can let in rain, snow, condensation, or ice that can spell disaster for both pedestrian and forklift traffic.

Additional injuries

Slips and falls are not the only types of injuries that loading dock doors need to contend with. The National Weather Service (NWS) provides data showing both hurricanes and tornados are the second- and third-most fatal weather hazards in the United States over the past decade—up from the previous 30-year average.

Over the past few years, hurricanes have made headlines and caused billions of dollars in damage to structures and products, and injuries to people, along the Gulf Coast and Eastern Seaboard. All the country’s coastlines and low-lying inland areas are susceptible to high-wind events associated with these storms and the potential devastation they cause when wind speeds can range from 144 to 241 km/h (90 to 150 mph). Even if an area has been spared from dealing with these disasters in the past, building owners should be prepared for whatever nature blows their way.

Of particular concern are commercial operations, especially warehouses and distribution facilities that find themselves increasingly exposed to danger and injuries as a result of numerous overhead doors and 24-hour operation. The potential for billions of dollars in damage and injuries to personnel when a hurricane makes landfall, or a tornado touches down, is motivation enough to storm-proof operations during construction.

Having a door that can withstand high winds is crucial to a building’s survival and employee safety. About half of the damage to a distribution center’s contents, and injuries sustained by employees during these events, is a result of the dock doors being ripped from their tracks and off the walls.

Moreover, the door is the only moving part one must consider on the building’s structure. Most other components—such as the walls or roof—are securely fastened into the building materials. In the parts of the country that will experience these devastating storms and tornados, commercial buildings must have doors that stand up to the pounding wind and flying debris, yet do what they are supposed to routinely do, which is open and close to efficiently handle truck traffic on the loading dock.

Whenever commercial building owners are unaware of the importance of proactively designing and building to reduce damage to their facilities and the disruption to their schedules, the insurance companies and, consequently, the code-writers for state and local governments, will remind them.

Traditionally, the South has been the busiest and hardest hit by hurricanes and tornados. However, as of late, the Northeastern Seaboard has also fallen victim to some of Mother Nature’s most devastating storms. In the wake of 2012’s Hurricane Sandy, facilities from Canada to North Carolina to Wisconsin have seen the effects these storms can have.

Storm damage

Do super-storms, high-wind events, and the potential devastation provide companies with an option to help reduce losses from facility damage and business interruptions? How can warehouses and other facilities protect assets from these storms?

In 2013, the American Society of Civil Engineers (ASCE) released a new edition of Wind Loads, a guide focused on ASCE/Structural Engineering Institute (SEI) 7-10, Minimum Design Loads for Buildings and Other Structures. This revised text includes information dedicated to wind load provisions for both residential and commercial buildings. Aimed at an audience of architects, engineers, and specifiers, it includes simplified calculation methods and guidelines to help these professionals provide clients with the most accurate recommendations to protect buildings.

The result of Hurricane Andrew’s impact in 1992, that caused $26.5 billion dollars and killed 65 people, was an updated ASCE Wind Loads guide. The storm also led Florida to enact the country’s toughest state building codes to ensure structures are tougher than the storms. These regulations encompass 24 product categories—including overhead sectional doors.

Florida requires buildings and their components, including doors, withstand wind pressures generated by winds ranging from 177 to 241 kph (110 to 150 mph). Additionally, the doors must stand up to a level of ultraviolet (UV) rays from the sun that could compromise the strength of the panels. It is no wonder Miami-Dade County is leading the building standards charge against Mother Nature in light of the devastation left from Andrew.

Notice of approval

Within the world of building codes, ‘wind load’ refers to the pressures exerted on a structure and the components comprising the structure due to wind. Wind pressures are assumed to act both toward (i.e. positive pressure) and away (i.e. negative pressure) from a building’s surface.

Stepping into this role as a building protector are wind-load-rated, impactable loading dock doors, already designed to stand up to impacts on the inside of the building. Now, these doors are available in wind-load-rated designs to even meet the Miami-Dade requirements for resistance to forces and impacts outside the building.2

Impactable dock doors were introduced to address the common damage and downtime issues associated with traditional metal overhead doors used in distribution centers and warehouses. Traditionally, these openings are similar to a standard garage door, and hardly built to take a hit from a forklift much less withstand hurricane force winds.

The widely accepted use of impactable dock doors has enabled distribution centers, manufacturing plants, and other commercial facilities to address the common damage and downtime issues that come with forklift impacts, saving considerable damage, energy loss, and reducing operating costs.

With an impactable door protecting against forklift impacts inside the facility, a logical next step was to enable them to stand up to high-wind events and flying debris from hurricanes, tropical storms, or tornados that can injure employees on the docks and in other areas of a facility.

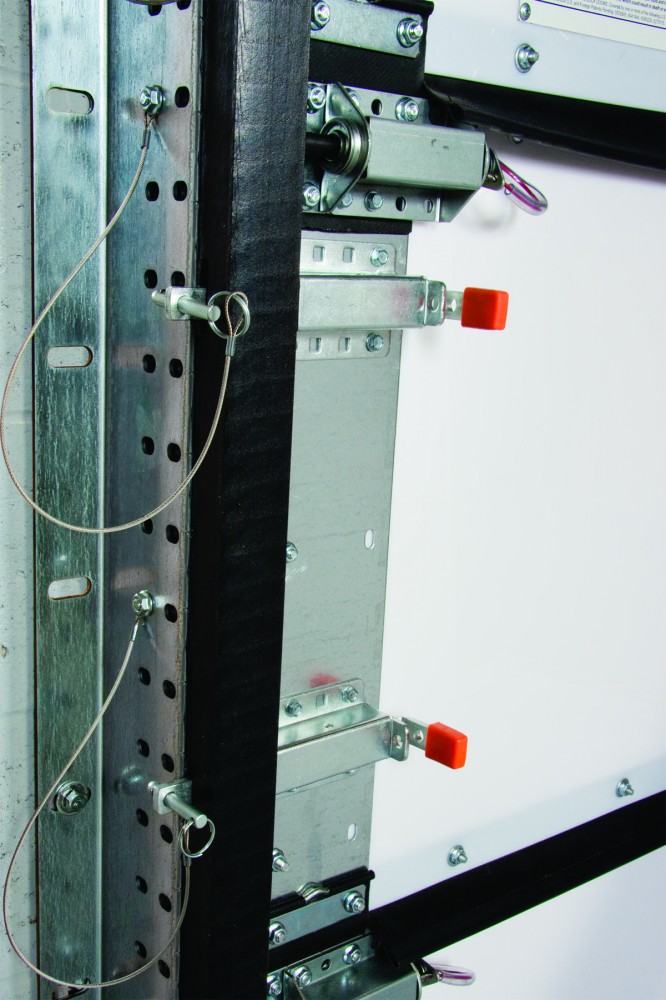

The features of these wind-load doors are similar to those on standard impactable doors mentioned earlier that can help prevent moisture infiltration and subsequently slips and falls, with an extra layer of protection. They include heavy-duty, retractable plungers, an impactable track, damage-resistant panels with polycarbonate skin, and slide locks with lock-out pins.

If a forklift or flying debris collides into an impactable dock door, the heavy-duty retractable plungers release the panel from the door guide, absorbing the impact and preventing damage or injuries. The damage-resistant panels with polycarbonate skin also guard against damage from flying debris and materials, as well as provide a layer of UV protection from the sun’s harmful rays that can weaken the doors panels.

The high-density impactable tracks mounted flush to the jambs are another part of these unique wind-load-rated impactable assemblies, which enable the door to remain attached to the wall. Unlike standard door tracks, the high-density tracks fight off the most abusive forklift impacts on the inside, while providing the necessary strength to withstand negative and positive wind pressures on the outside during a storm.

In regard to wind storms, negative wind pressures are a particular issue with overhead doors in general. To combat these forces, wind-load-rated impactable doors have multiple slide-locks mounted securely to a steel plate on the panels. As a storm approaches, the crew can engage the slide locks into holes along the height of the guide track and secure with a pin attached to the tracks. This is an extremely important consideration in facilities that have a large number of these doors with limited time and resources to prepare for a high-wind event.

As a way to combat these high-wind events in accordance with the Florida Building Code (FBC), rigorous testing establishes if a door design meets static air pressure resistance required by American National Standards Institute/Door and Access Systems Manufactures Association (ANSI/DASMA) 108, Standard Method for Testing Sectional Garage Doors and Rolling Doors: Determination of Structural Performance Under Uniform Static Air Pressure Difference, or ASTM E330, Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights, and Curtain Walls by Uniform Static Air Pressure Difference, specifications. Though static air pressure (positive and negative) is one issue (measured in lb/sf), some localities are requiring door testing to determine the ability to resist penetration of airborne debris. The testing involves hundreds of simulated wind gusts and impacts from a 2×4 stud shot from a cannon at 15.24 m/second (50 ft/second).

Essentially, these impactable door designs meet FBC as determined by the testing. The same door panels, which stand up to the forceful impact of speeding forklifts carrying heavy loads, were able to pass the wind gust and projectile tests and still provide coverage for the doorway. To provide additional assurance to overcome these forces, there is a flexible tubular frame reinforced with a steel angle inside the panels.

Conclusion

While facilities in the Gulf region and other areas along the Atlantic Coast have suffered billions of dollars of damage and injury due to high winds, innovative and stringently tested wind-load-rated impactable doors can help distribution and warehouses facilities of all sizes obtain reduced property damage and maintain a more secure loading dock after the storm, leading to minimal disruption to the supply chain and help reduce slip and fall injuries.

Notes

1 For more information, visit www.bls.gov/news.release/archives/osh_11072013.htm. (back to top)

2 Visit www.miamidade.gov/building/pc-result_app.asp?fldNOA=11-0513.04&BasicSearch=Go&Classification=0%2CUnknown+%2F+Unselected%2C1&applicantlist=0&categorylist=0&subcategorylist=0&materiallist=0&impactlist=0&fldMDPP=0.00&fldMDPN=0.00. (back to top)

Josh Brown has been in the dock and door industry for the last 13 years. He represented two dock equipment lines for six years, and has been managing TKO Dock Door sales for the last seven. Brown can be contacted by e-mail at sales@tkodoors.com.

To read the sidebar, “Impactable Dock Doors: Florida Building Code (FBC) 1715.5.3, ‘Exterior Door Assemblies,’” click here.

These sounds like really great doors and are probably very very safe for the workers. I would imagine that warehouses need doors that can take a beating when a forklift or a truck gets too close. I agree that it is very important to make sure that safe comes first.

Great read. Impact doors not only ensure the safety in warehouses but also gives a strong protection to our home in heavy storms. Moreover, impact door and window gives the protection from ultraviolet rays too. These windows are also know as hurricane impact windows. These windows and doors provide safety in every climatic conditions and prevent the unwanted entries in home too. The source (http://stormguardwindowanddoor.com) illustrate the more information regarding the benefits of installing the impact door and window.

I found your blog to be very informative. I am greatly inspired by your posts and thinking of writing mine now.

We required service on our ware house dock doors