Key considerations for designing fenestration systems for success

Punched windows

A stainless steel or copper, fully soldered sill pan with end dams and a back dam is essential in a fenestration system for collecting any potential leakage and directing it out of the building, especially for punched windows (Figure 5).

Unfortunately, due to the complexity of installation, the coordination required, and the additional cost for materials and installation, this sill pan flashing is often removed during the value engineering process, leaving just a few sealant joints or flat sections of sheet membrane to protect the openings. Flashing may also be changed to aluminum which relies on sealed corners at end/back dams.

While better than no metal flashing at all, sealed corners represent a common point of failure and source of leakage. It is often argued a window with a sill receptor does not require a sill pan flashing since the “receptor is designed to be watertight.” However, leakage can still occur from windowsill receptors and without a dedicated sill pan, the leakage will make its way to the interior. Common leaks through window sill receptors include not fully sealed end dams or penetrations through the sill receptor.

Window wall

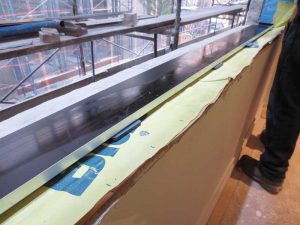

A basic detail for projects with a window wall system is a sill depression at concrete slab edges (Figure 6). This depression should be lined with waterproofing material that extends up the backside to create a pan. With this detailing, any leaks from the system are captured and cannot physically migrate to the interior due to the depression.

Typically, the depression extends several millimeters (inches) inboard of the system itself to accommodate structural attachments. When this detail is included in the final construction documents, it typically gets built as intended as it is easy to execute and does not significantly impact the cost.

In lieu of a slab depression, a sill pan could be installed below a window wall system. However, this would be impractical given the anchor penetrations through the sill pan or anchors interrupting the back dam, in addition to being more expensive than simply blocking out the slab edge during concrete placement. This makes the slab depression a much simpler method of containing potential leakage at the base of a window wall system.