Modular Carpet Needs a Plan: The strategy of installation methods

Step 1

If carpet is manufactured in 1.8-m (6-ft) widths, it can go from production directly to the tile line for backing application and ‘clicking’ off into desired tile sizes of:

- 457 x 457 mm (18 x 18 in.);

- 610 x 610 mm (24 x 24 in.);

- 914 x 914 mm (36 x 36 in.); or

- 457 x 914 mm (18 x 36 in.)

The 3.6-m (12-ft) wide carpet is cut to 1.8-m (6-ft) wide rolls and then subject to the same procedure.

To determine a recommended installation method, a physical installation mockup must first be created. This entails installing the modular carpet in all possible methods and effectively grading the appearance both in product and general seam ability. The decision to not recommend a particular installation method is decided at this juncture. During the mockup phase, products are critiqued by upper management, product design, manufacturing, and field technical services personnel for appearance and recommended installation practices.

Step 2

If the product’s appearance is approved, it is then examined on a seam appearance level, subjecting it to the many methods of carpet tile installations. In this phase, the true installation methods come to light. Seam appearance by product varies widely by install method—when a product is approved for a specific installation method, it means the general public will not find the seams objectionable. This process eliminates the speculation for product-specific carpet tile installations, yields an endorsed installation method tailored to each product, and is assured by the company’s best practices for products.

Step 3

With each product, company-approved guides for proper carpet tile installation methods are provided with basic visual layouts and reference materials. If there are any questions about the recommended layout, the company should be available to clients to provide assistance. However, the best and safest practice is to show the potential client a physical mockup to gain approval for a ‘no-surprise’ installation appearance. With the client’s approval on the mockup level, and the manufacturer’s approval from the manufacturing side, satisfaction is inherently the result.

Conclusion

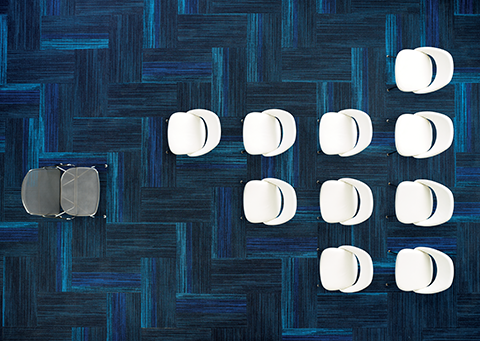

Carpet tile installation methods provide clients with numerous aesthetic options. The versatility of carpet tiles is what makes it an interesting material. There are many distinctive tile sizes, shapes, patterns, and colors. Depending on the shape and size, designers can create unique projects. The caveat to remember is not all products can be installed in all installation methods, but with the recommended foundation and a solid plan, one can develop successful designs.

Bob Reince is the senior director of technical services at Bentley Mills. Initially joining as assistant manager of technical services in 1989, he grew with the company and was sought out to venture to new opportunities in 1999. However, he remained in the technical and field service divisions of the commercial carpet industry at the top of his level. Coming full circle, Reince rejoined Bentley in April 2012, assisting in its newest rebranding strategy on the technical service level. He can be reached via e-mail at bob.reince@bentleymills.com.