Bridging form and function with modern rainscreens

Weather-resistive barrier

Weather-resistive barrier

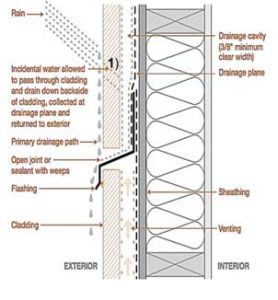

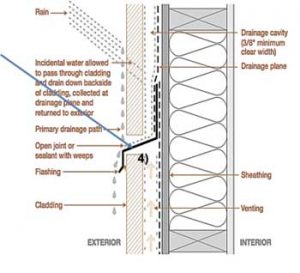

The weather-resistive barrier (WRB) is located behind the air gap. The 2018 IBC section 1402.2 states that a building’s exterior walls must be covered with a weather-resistant exterior envelope. A water-resistive barrier covers the building envelope to prevent the accumulation of moisture within the wall assembly.

For a drainage plane to be effective, it must be continuous and integrated with flashings. The most common material for this layer is a building wrap, which resists the penetration of water from the exterior into interior sheathing. It also allows the passage of vapor/trapped moisture from the interior into the gap. A WRB also functions as an air barrier and prevents external air from passing through the envelope into the interior. Building felts and various troweled materials and foam insulators are also suitable for this layer. The capacity of this layer compensates for inadequacies in the cladding. In an ideal system, this layer never gets wet. In the worst case, it should only be subjected to a small amount of moisture under low pressure.

Flashing

Flashing

The final component is flashing, thin pieces of impervious metal installed over openings in the wall, around the inside and outside corners, and where cladding styles change to prevent the passage of water into the structure. Flashing is intended

to direct water to the outside of the cladding. Additionally, flashing helps to prevent water penetration at windows, doors, vents, pipes, and other openings to make a building more durable and reduce or prevent moisture management problems. Flashings must be carefully sealed into the WRB to function properly. Metal flashings include aluminum, copper, stainless steel, and galvanized metals. Fluid-applied flashings are alternative products that provide continuous coverage around windows, doors, penetrations, and transitions within the building envelope.