Building faster: The role of smart coatings

As the global demand for semiconductors continues to accelerate, general contractors (GCs) are being tasked with building some of the most complex facilities in the world—and doing it faster than ever before. These fabrication plants are high-stakes endeavors, where every delay can cost millions and impact critical supply chains. A recent survey revealed that 87 percent of construction professionals identified delays as the single most significant obstacle in delivering these facilities on time.1

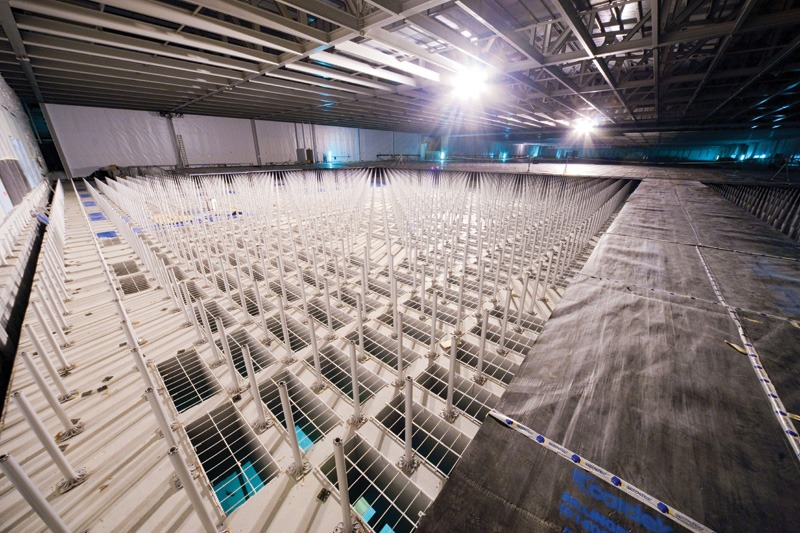

These projects are anything but standard. They are sprawling, multi-billion-dollar campuses built to accommodate highly sensitive technologies in controlled environments. From ISO-certified clean zones to utility floors housing high-performance systems, every square foot must be built to exacting standards. For GCs, this means coordinating trades, navigating strict specifications, and managing timelines with precision. Any misstep can have negative impacts across the project, causing costly rework, safety risks, and missed deadlines.

Three pressures GCs face on advanced manufacturing construction jobs

In the author’s experience across various advanced manufacturing industries, including the semiconductor industry, they have seen three core issues consistently challenge GCs:

- Schedule pressure—Owners expect speed and certainty. With massive investments on the line, even minor delays can push back production timelines by months, costing millions in lost productivity.

- Labor shortages—Skilled tradespeople with experience in these types of facilities are hard to come by. In the same research survey mentioned previously, 36 percent of construction professionals identified labor shortages as one of the biggest challenges facing their mega construction projects. Projects need systems that reduce the learning curve, simplify application, and demand less specialized labor.

- Complex coordination—Advanced manu-facturing projects require tight coordination across trades. Misalignment leads to delays, rework, and added cost.

Coatings systems have to be designed with these challenges in mind. Coating solutions should be engineered to not just meet specs, but to help GCs overcome friction and keep projects moving.

More than paint: Coatings as a construction tool

Coatings are often seen as a finishing touch applied at the end of the build. However, in semiconductor fabrication construction, coatings play a far more critical role. High-performance coatings protect clean zones, structural steel, and critical substrates from corrosion, chemical exposure, and premature wear. Just as importantly, they can significantly impact construction timelines with their ability to be applied offsite. When using offsite shop-applied fireproofing, steel erection time can be significantly reduced.

By engaging early with design and construction teams, the right partner can help GCs streamline workflows, minimize rework, and reduce trade stacking. It is important to have systems that are engineered not just for protection, but for real-world construction, supporting faster builds, safer sites, and better project outcomes.

Offsite application: Shifting the schedule

One of the most effective ways to decrease risk in a project is through offsite application of coatings. With shop-application, coatings are applied in controlled environments before the substrates arrive on site. This eliminates weather-related delays, improves quality assurance, and reduces congestion at the jobsite.

For semiconductor fabrication facilities, the most common offsite applications include high-performance coatings such as epoxies, urethanes, and polysiloxanes, as well as epoxy intumescent fireproofing. The key consideration in selecting these systems is durability—not only their ability to perform in the service environment and meet the expected lifecycle, but also their resilience during loading, transport, storage, and erection. If a coating system requires extensive repair after installation, any potential time or cost savings are quickly lost.

For GCs, this translates into a smoother construction sequence. Pre-coated steel or concrete components arrive ready for installation, enabling parallel workflows and limiting the bottlenecks that typically slow down progress.

These applications may be performed at the steel fabricator, in specialized coating facilities dedicated to surface preparation and

high-performance application, or in temporary enclosures set up on or near the jobsite. In each case, the goal is to maintain a controlled environment that allows coating work to proceed without disrupting the broader construction process. It is a shift to a method that is already accelerating schedules on some of the world’s largest manufacturing builds.

Zone-specific solutions for every part of the build

There is no one-size-fits-all solution in semiconductor fabrication facility construction. Each zone within a fabrication has unique performance demands and the coatings must be tailored accordingly. Some examples include:

- Low-VOC, contamination-resistant coatings that support ISO cleanroom standards.

- Chemical-resistant tank linings that help manage wastewater and maintain environmental compliance.

- Fireproofing systems that meet rigorous safety standards without delaying on-site construction.

Each coating system should be validated through real-world application and supported by experts who understand how to integrate these tailored systems into the construction process with minimal disruption.

When durable coating systems are selected to withstand loading, transport, and erection, the need for touch-ups in the field is typically minimal. That said, a repair plan should always be in place. The coatings manufacturer should provide guidance on proper repair procedures, and responsibility for carrying out those repairs should be clearly assigned in advance to the party owning that scope of work.

Why early involvement matters

The earlier the right partner is involved, the better. By consulting the coatings manufacturer during preconstruction, they can help identify coatings solutions that align with sequencing, labor availability, and performance specs.

The earlier these elements are specified, the better, although early coordination is not always possible. In many cases, general contractors, steel fabricators, and coating applicators have successfully integrated offsite manufacturing (OSM) into their plans from the outset. In other situations, OSM has been introduced later in the process, with workable solutions still being developed even just before steel erection. Offsite surface preparation and coating can also be carried out in temporary enclosures near the building footprint, providing flexibility when early planning is not feasible. This approach results in fewer changes down the line, reduced challenges on site, and improved coordination with other trades.

The right manufacturer also helps evaluate trade-offs, for example, how a coating choice may impact drying times, environmental conditions, or substrate compatibility. It is this level of planning that helps avoid schedule slips and keeps momentum strong throughout the build.

The ROI of smarter coating strategies

Investing in high-performance coatings reduces long-term maintenance costs, directly improving the ability to hit milestones, meet safety and compliance standards, and turn over the facility on time. When coatings are easy to apply, do not require excessive prep work, and integrate cleanly into the construction timeline, the benefits are felt across the value chain.

Do not let the finish line be the bottleneck

While one may not think of coatings as the biggest part of their project, it can be one of the smartest ways to keep it on schedule. The right coatings provider can simplify construction and help GCs deliver these critical projects with confidence. In the competitive world of semiconductor fabrication construction, getting a facility online faster can mean everything.

In addition, because certain coatings systems can be designed with sustainability in mind, such as low-VOC formulas and durable linings that reduce lifecycle impact, they help GCs support the environmental commitments of their clients.

Notes

Author

Mark Wafford is a construction solutions executive dedicated to the semiconductor manufacturing market at Sherwin-Williams Protective & Marine (SWPM). He has spent 23 years in the coatings industry with Sherwin-Williams, with over 10 of those years focused on protective coatings, and he is an Association for Materials Protection and Performance (AMPP) senior certified coatings inspector. His primary focus in this role is to establish strong relationships with general contractors, architects, and engineers active in this market.

Key Takeaways

Semiconductor fabrication facilities are complex, high-stakes projects where delays cost millions. General contractors face pressure from tight schedules, labor shortages, and coordination challenges. High-performance coatings—especially when applied offsite—streamline workflows by reducing rework, avoiding weather delays, and enabling faster installation. Zone-specific solutions, including cleanroom finishes, chemical-resistant linings, and fireproofing, must be planned early. Durable, low-maintenance coatings not only protect assets but also improve safety, efficiency, and on-time delivery of advanced manufacturing facilities.