Selecting and specifying roof coatings

From a building code perspective, a coating can be applied on new and existing roofs as a maintenance item; application of a roof coating is not considered to be the application

of a new roof. Therefore, an existing roof can be coated or re-coated at any time—for example, a building owner can add a highly reflective roof coating to reduce energy costs. Additionally, applicators of a roof coating on an existing roof should consider any in-place warranties so they are not voided or violated.

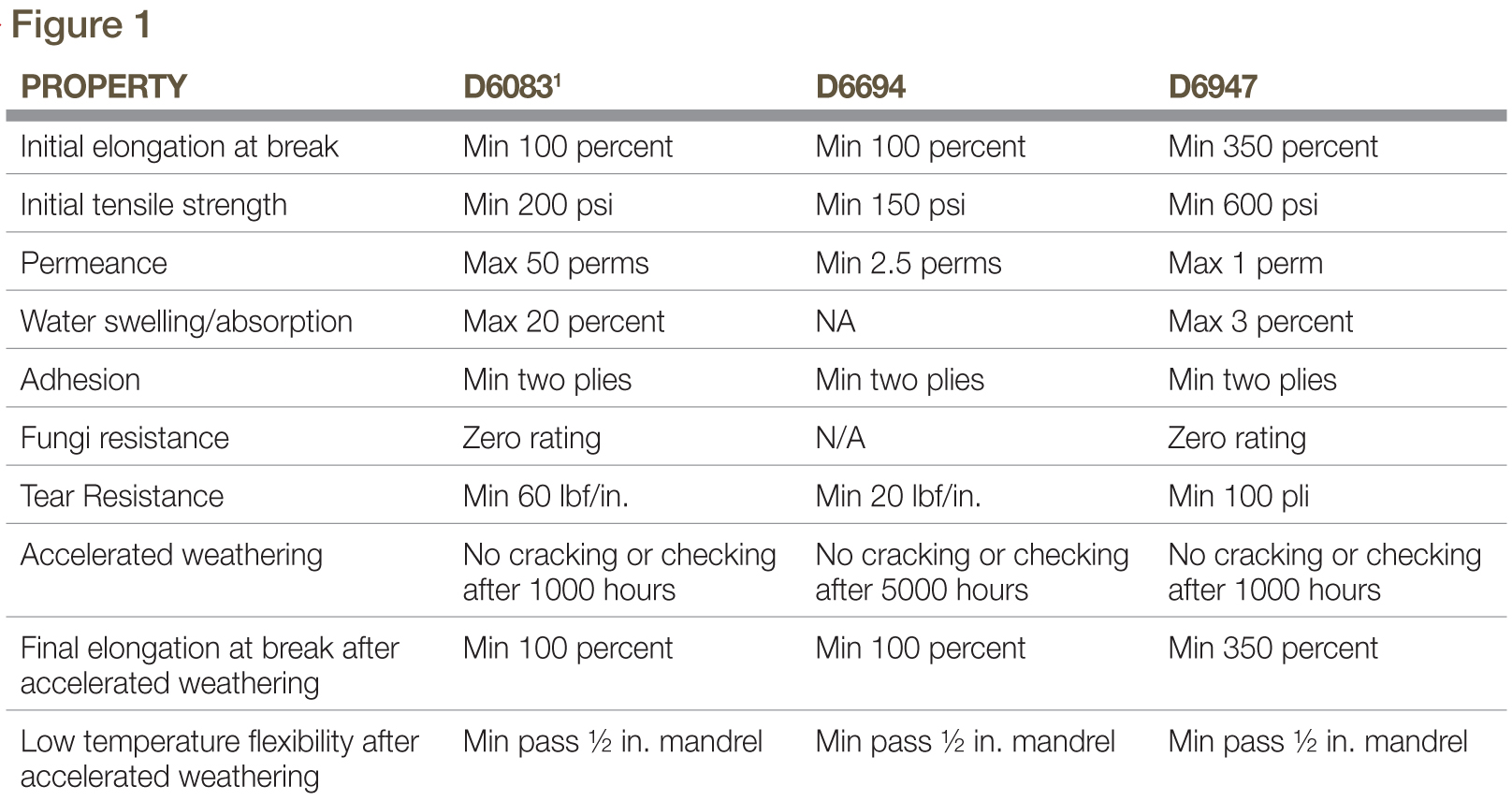

The 2015 IBC lists acrylic, silicone, and moisture-cured polyurethane coatings for use on SPF roofs. Each has an ASTM material standard that each type of coating must meet.

- ASTM D 6083-05e01, Standard Specification for Liquid-applied Acrylic Coating Used in Roofing;

- ASTM D 6694-08, Standard Specification for Liquid-applied Silicone Coating Used in Spray Polyurethane Foam Roofing Systems; and

- ASTM D 6947-07, Standard Specification for Liquid-applied Moisture-cured Polyurethane Coating Used in Spray Polyurethane Foam Roofing System.

Figure 1 lists film physical property requirements for each coating type.

To date, there are numerous coating types that do not have consensus standards (e.g. ASTM) for minimum properties. Specifying coatings that do not have a consensus standard should be based on physical properties provided by manufacturers. Some of the coating types that do not have an associated ASTM standard include polyureas, aliphatic polyurethanes, aromatic urethanes, butyl, and SEBS coatings.

Application considerations

Coating application includes considerations such as;

- storage;

- surface and substrate preparation;

- primer use;

- application specifics; and

- curing and drying time.

Storage

One should always keep roof coatings stored as close as possible to room temperature. In cold weather, a heated warehouse is generally the preferred type of storage area. Water-based products susceptible to freezing may be damaged or rendered useless if subject to temperatures at or below 0 C (32 F).

Surface and substrate preparation

The roof must be thoroughly cleaned, and allowed to dry completely. This is a critical step to ensure a successful coating application. Dust, chalking film, bitumen exudate, grease, oil, and other loose debris should be cleaned off the roof surface before the coating application. Care should be taken when pressure-washing to not disturb the integrity of the underlying roof membrane, particularly where there are adhered seams. Roof coatings should never be applied to a frost-, snow-, or ice-covered surface. In addition, for most solvent-based roof coatings, the surface must be dry unless the coating has been specifically formulated for adhesion to wet surfaces. It is advisable to apply coatings only when there is a minimum of 24 hours before forecasted rain. Coating manufacturers have specific requirements for roof preparation.

Primer use

Primers are designed to prepare the roof surface for accepting a coating and improving the overall adhesion. However, a primer is never a substitute for proper surface preparation. Typically, these products exhibit low viscosity and are formulated to quickly wet the substrate in a thin layer. When cured, it will leave behind a thin film acceptable for receiving a coating. Primers are available in various binder and solvent combinations, and the type used in a particular application will be based on the substrate, weather conditions, and coating type.

Any required roof or flashing repairs should be completed and allowed to adequately cure as necessary. Some water-based primers may be applied to damp, but not wet, surfaces. Coating manufacturers can be consulted about non-dry surface application. Applying the surface coating should occur soon after the primer has been spread and cured to ensure the desired results.

Surfaces that generally require primer include metal flashings, gravel stops, and other metal edging. Certain roof substrates may require priming not only to promote adhesion, but also to prevent the substrate from negatively impacting the coating performance. For example, rust-inhibitive primers are often used to prevent rust/corrosion on metal flashings from transferring through to the surface of a water-based coating.