Specifying multi-function solid-surface sinks

How to specify

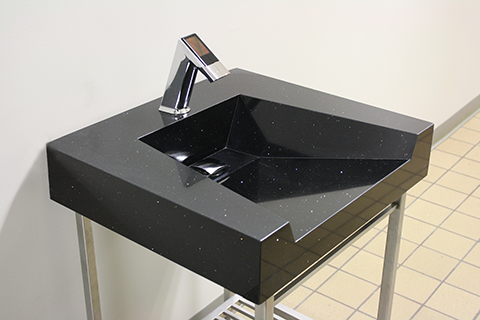

When specifying these new faucet-soap-dryer models (after considering facility type and restroom patterns), specifiers should focus on the need for durability and design. When both durability and the design are part of the restroom’s objectives, this new option presents itself as a viable alternative to traditional separate functionality solutions.

In a best-case scenario, such a combination unit would be available from one manufacturer. Ideally there would be options in each category to choose from to meet any application. However, if the criteria go beyond each category, then a custom specification may be necessary.

Some considerations for the project specification include:

- ergonomic hand-washing basin available in single-, double-, and triple-user stations;

- sink must enable point-of-use sensor operations for faucets, soap dispensers, and deck-mount hand-dryers; and

- material should be stain-, chemical-, scratch-, and impact-resistant.

In addition to the overall sink itself, the specifier should consider the following requirements for faucets:

- demonstrate interchangeability of components to simplify orders, upgrades, repairs, and maintenance;

- offer multiple power-harvesting options to suit the environment’s unique needs;

- provide multi-laminar spray—full-stream aerated or full-stream laminar—with adjustability flow rates as an option; and

- include a line purge function to eliminate the stagnant water that can lead to bacterial growth.

Electrical specifications should include:

- control circuit: 6.75 volts direct current (VDC);

- sensor range–factory setting: 102 to 127 mm (4 to 5 in.);

- battery life: five-years under worst-case conditions of 8000 cycles/month and high water pressure without power-harvesting which should extend service life of battery; and

- nominal range adjustment: 51 to 356 mm (2 to 14 in.) nominal;

- power supplies: 6 VDC alkaline battery pack.

While not necessarily the specifier’s responsibility, consideration should be given to warranty on these new multi-function sinks. The better the warranty, the more confident the manufacturer is in the product’s performance over a minimum of three years. Of course, the sinks must also meet the applicable codes and standards, which include:

- American Society of Mechanical Engineers (ASME) A112.18.1/CSA B125.1, Plumbing Supply Fittings;

- NSF 372, Drinking Water System Components–Lead Content;

- ANSI/Underwriters Laboratories (UL) 1951, Standard for Safety–Electric Plumbing Accessories;

- International Code Council/American National Standards Institute (ICC/ANSI) 117.1, Accessible and Usable Buildings and Facilities;

- UL 499, Standard for Electric Heating Appliances;

- UL 507, Standard for Electric Fans;

- International Association of Plumbing and Mechanical Officials (IAPMO) Guide Criteria (IGC) 156, Wash Fountains And Lavatory Systems With or Without Water Closet; and

- IGC 127, Combined Hand-Washing Systems.

When applicable, specifiers and design teams should also be aware of:

- Uniform Plumbing Code (UPC);

- International Plumbing Code (IPC);

- California Green Building Code (CALGreen); and

- City of Los Angeles Water Efficiency Ordinance.

Legislative compliance is important as well, which includes the Federal Reduction of Lead in Drinking Water Act, Law 111-380 (i.e. contains no more than 0.25 percent weighted average lead content), Section 116875 of the California Health and Safety Code, and Vermont Lead Reduction Law.

From a plumbing perspective, specifying commercial sink systems is not as easy as it used to be. However, this is a good thing, because it brings more options to specifiers and project teams. There are many factors to consider, and there are more choices in integrated technologies and fixtures than ever before, and the sheer breadth of options can be daunting. Keeping the basic issues in mind can help the specifier make a clear choice.

Steve Connaughton is the sink system and programmed water technologies (PWT) product line manager for Sloan Valve Company. For more than 30 years, he has worked in numerous sales and management capacities for Sloan. Connaughton can be reached at steve.connaughton@sloanvalve.com.