System intelligence: The rise of rainscreen technology in building longevity

Rainscreen technology is revolutionizing building envelope performance, significantly contributing to the longevity and resilience of modern structures. However, neither this technology nor the idea appeared overnight. It is the result of knowledge accumulated over centuries and evolving technology. In this article, explore where the concept of a building envelope began and how it evolved into today’s advanced components. Before travelling back in time to the roots of this building concept, let’s define what a rainscreen is designed to do.

The rainscreen system defined

Since “rain” is in the name, many laymen believe the primary function of a rainscreen is to act as a barrier against water penetration. However, that role belongs to the air- and water-resistive barrier (AWRB). A rainscreen is designed to limit the amount of water that could potentially come into contact with the primary building envelope’s WRB, reducing the risk of moisture intrusion by resisting five key forces: kinetic energy, gravity, capillary action, surface tension, and pressure gradients.1

The origins of the rainscreen concept

The term “rainscreen” has been around since the 1960s, although it usually referenced cladding material. The idea of creating a weather-tight seal around a structure has been traced all the way back to 12th-century Norway.

The “open-jointed barn technique” earned its name because it was a design used primarily in the construction of barns. This method consisted of timber claddings adjoined to traditional stone walls, using closed joints down the sides and open ones at the top and bottom to allow rainwater to drain away or evaporate.2

From this early milestone, rainscreens would continue to evolve and the idea really took hold in the 20th century. The Alcoa building in Pittsburgh, originally designed by the architect Harrison + Abramovitz was one of the first large buildings to use modern rainscreen cladding. According to building science professor John Straube (RDH Building Science Laboratories), the 30-story Alcoa building, built in 1952, was an early example of a structure with a “pressure-moderated” ventilated outer wall. It was clad with large, baffled aluminum panels, which provided resistance to water penetration. Ventilation was provided in the airspace between the cladding and the main wall to dry any moisture.

Building researchers and scientists began testing and validating open rainscreen systems, as well as simple vented and drained systems, in the 1960s. This foundational work led to continued research and refinements in Canada and Europe throughout the late 1960s and 1970s. In 1971, the American Architectural Manufacturer’s Association (AAMA) published the first formal guide for pressure-equalizing designs, building on these earlier developments.3

By the 1980s, the principles of rainscreen cladding were well understood and widely used throughout Europe. As the science behind these systems improved and there was clear data to support the performance claims, rainscreens became the norm in the U.S. as well.

The difference between then and now

While contractors and craftsmen have been doing their very best to construct energy-efficient buildings that stand up to the elements through the centuries, the most significant flaw in their approach was the lack of a single unified and comprehensive solution. Instead, multiple craftspeople and contractors executed a piecemeal solution. Current best practices clearly identify that properly sealing a building and creating a truly functional, comprehensive envelope requires a single, cohesive system.

Modern rainscreens use this comprehensive and cohesive system approach with the best, most functional systems employing a common baseline structural substratum. Building on a common substrate with a uniform foundation streamlines the installation process and offers unmatched versatility that then allows nearly every cladding finish or type to be installed over it. As a result, architects and specifiers can achieve seamless transitions between significantly different cladding materials to achieve looks and textures within the same project, marrying aesthetic flexibility with robust, high-performance functionality.

Advanced components of a modern rainscreen system

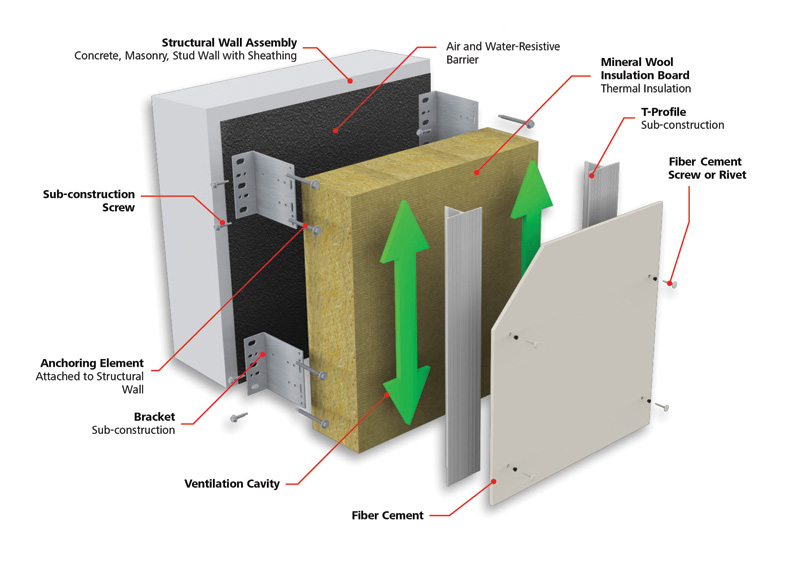

Today’s rainscreens are made up of several key structural components, each serving a critical role in moisture management, energy efficiency, and durability; these components typically include:

- Outer cladding material—Cladding serves as the primary barrier between a building and the elements. Material selection should be based on the building’s climate zone and exposure to environmental hazards. Materials such as fiber cement, metal panels, high-pressure laminate (HPL), or specialized render systems can be customized with site-specific conditions in mind to meet the required level of protection. Specialized render systems refer to advanced, multi-layered exterior finish systems—typically including a base coat, mesh reinforcement, and finish layers—that are formulated to deliver specific performance benefits such as weather resistance, impact durability, vapor permeability, or fire performance. Many of these systems are available as pre-engineered assemblies, tested to meet established standards for factors like wind loads, thermal values, or fire resistance, helping to streamline specification, ensure code compliance, and reduce field coordination challenges during construction.

- Air gap or cavity—A ventilated space behind the cladding that helps manage moisture. A modern rainscreen system incorporates a larger air gap to promote drainage and drying of wall assemblies.

- AWRB—This is attached directly to the building’s frame and is the last line of defense against air leakage and moisture intrusion. Depending on the climate, the AWRB may be permeable or impermeable to water vapor.

- Exterior insulation (a building’s thermal overcoat)—This outer layer of insulation can handle some moisture and drying without degrading or reducing its R-value. Depending on the building owner’s thermal requirements and targets, this layer may be supplemented. Locally adopted energy codes require different degrees of exterior wall thermal performance.

- Venting profiles—Modern construction detailing offers a wide variety of ventilation options to help direct moisture away from the wall surfaces while remaining successful at keeping out pests.

System intelligence examples

The performance of a rainscreen is only as reliable as its individual components. The individual components must work in concert to manage moisture, withstand site-specific and sometimes extreme wind loads, and still enhance fire resistance. If one component underperforms or fails, the entire system fails.

Engineered for modern construction, a robust system can offer advanced thermal performance, fire protection, and weather resistance, with features that can include non-combustible continuous insulation (c.i.), a weather-tight AWRB, thermally broken adjustable sub-construction, and high-density, non-combustible fiber cement panels.

Fiber cement offers flexibility in design through shapes, color, texture, perforations, and visible or concealed fastening. It uses the same sub-construction as other cladding options. These design choices are easily integrated to complement or contrast with the fiber cement. Combined with recognized compliance under AAMA and NFPA standards, a well-designed rainscreen system delivers the versatility and compliance architects trust. Mix and match any cladding texture, material, shape, or color to create a true original.

Benefits of well-designed, properly installed rainscreen

A rainscreen system is designed to protect inner walls from weather exposure and prevent water and moisture from penetrating the building envelope. With today’s systems, that is only where the benefits begin.

- Energy efficiency—Rainscreen cladding improves thermal performance, reducing heating and air conditioning costs by up to 40 percent annually.

- Insulation—An added insulation layer enhances thermal efficiency and limits condensation.

- Protection—The cladding protects the building’s exterior from wind, rain, and snow, extending its lifespan and reducing maintenance costs.

- Structural stability—The air cavity in the rainscreen mitigates temperature variations, reducing structural movements and the risk of cracks.

- Acoustic insulation—An additional layer of insulation helps block outside noise, which is beneficial in urban environments and especially important in healthcare or wellness facilities.

- Design freedom—A rainscreen system provides an exoskeletal structure that supports a variety of architectural finishes.

How to choose the best rainscreen for a project

As demand for high-performance building envelopes has increased, so too has the number of manufacturers offering rainscreen solutions. Today, there are several excellent solutions on the market. When considering which product to invest in, ask these questions:

- Does the manufacturer offer a complete system? The fewer manufacturers to deal with, the easier the project will be. One manufacturer that provides everything from the sheathing out is ideal because one warranty will cover the entire system. The last thing one wants to do is stitch together a piecemeal system and hope that the subcontractors have successfully installed it to create a properly sealed envelope.

- Has the system undergone extensive testing? One of the most recognized tests for rainscreen systems is AAMA 509. It was the first North American testing standard for drained and back-ventilated (DBV) rainscreen cladding. This standard was developed to create a benchmark in DBV rainscreen performance and provides specific criteria for ventilation and moisture control. Make sure the selected rainscreen meets this standard. If unsure, just ask.

- Does the manufacturer offer on-site support? The right company will have project service managers who have a deep understanding of building science and can help with the needed systems. They will provide thermal modeling to help balance the thermal target with the structural loading and work with the general contractor to ensure the project progresses smoothly.

- Is a manufacturer with expertise in a particular area needed? This depends on the specifics of a project. For example, if there is significant water intrusion into the interior of the building, project teams may want to find a company with expertise in AWRBs. If extreme weather conditions are taking a toll on the cladding, consider retaining professional consulting services from a company with significant cladding expertise. The vast majority of larger manufacturers retain the knowledge and experience to solve virtually any problem with their in-house experts. Their experience is vast and will likely offer appropriate solutions to remedy the situation.

- Does the manufacturer offer a wide variety of design options? This is very important. If the rainscreen system has limited design options, the architect will be restricted in meeting the aesthetic goals of the project. By default, the system’s functionality is prioritized over the appearance of the building. Also, buildings need to be refreshed over time. By installing a system with endless design possibilities today, the option of updating only the cladding later expands greatly, as opposed to replacing the entire rainscreen to achieve the desired new look. The right product and manufacturer will offer a variety of design options so the client can achieve the desired look and feel now and in the future.

- Is the system eco-friendly? This is becoming increasingly important with every passing year. The system should be built for the future, offer lightweight solutions, use recycled materials, and incorporate sustainable components. Building codes are becoming stricter, and environmental considerations are becoming codified. The expectation is that building owners will do their part to be mindful of the environment in new construction and retrofits.

The future of rainscreens

While research and testing on rainscreens continues, there are initiatives to grow towards a standardized rainscreen specification and criteria that continue to gain traction. In 2020, a highly diverse community of industry professionals passionate about supporting performance-driven rainscreen assemblies joined forces to create an international not-for-profit industry association, called the Rainscreen Association in North America (RAiNA), dedicated to serving the rainscreen market in North America.

With the guidance of these industry groups, rest assured that these systems are only going to become easier to install, more reliable, and more versatile.

The rise of system intelligence

As discussed in earlier sections, such as “The difference between then and now,” which highlights the shift from piecemeal construction to unified systems, and “System intelligence examples,” which illustrates how components now work together for energy efficiency, fire protection, and design flexibility, the concept of the rainscreen has evolved through centuries of refinement. This progression has resulted in intelligent, high-performance systems that define contemporary cladding assemblies. As climate resilience, energy efficiency, and material performance become ever more critical, the integration and adaptability of rainscreen systems will continue to shape the future of sustainable architecture.

Notes

Author

David Hohenstern is StoVentec R&D manager at Sto Corp. He joined Sto in May 2022. He is a voting member of the C17 committee at ASTM, which owns and manages the fiber cement standards used in the Americas, as well as E05, the committee on Fire Standards, and E06 on Performance of Buildings. Hohenstern is a lifelong Georgia resident and a two-time graduate of the Georgia Institute of Technology.

Key Takeaways

Rainscreen technology has evolved over centuries into a key system for protecting buildings from moisture and environmental damage. Modern rainscreens include cladding, air gaps, air- and water-resistive barriers (AWRBs), insulation, and venting to improve energy efficiency, durability, and design flexibility. A well-designed system reduces maintenance and energy costs while enhancing performance. Choosing the right rainscreen involves evaluating full-system offerings, performance testing, on-site support, and sustainable materials. As the industry advances, rainscreens will continue to play a vital role in creating resilient, high-performance buildings.