Thinking Big: Seven considerations when specifying large insulating glass units

3. Wind load

As mentioned, large IG units are more likely to require heat-treating of the glass to resist breakage at specified wind loads, yet heat-treated and untreated (annealed) glass will always exhibit equal amounts of deflection (physical bowing) when exposed to the same wind load.

For this reason, large IG units must be designed to limit center-of-glass deflection to a degree that not only retains support of the IG unit where glass panels meet the framing, but also does not alarm building occupants on excessively windy days.

To ease such concerns, most glass manufacturers recommend IG units be designed to limit center-of-glass deflection—the amount of bowing from the edge of an IG unit to its center—to 19 mm (¾ in.) or less.

Figure 2 compares center-of-glass deflection calculations for six IG unit sizes at various assumed wind loads using ASTM E1300, Standard Practice for Determining Wind Load Resistance of Glass in Buildings.

4.Thermal stress

Large IG units typically require heat-treatment to resist thermal stress, particularly when tinted and/or high-performance low-e glass is specified for one or more lites. This is due to the fact tinted glass absorbs heat and low-e coatings reflect heat, which can exacerbate variations in temperature from the center to the edge of an IG unit, increasing the likelihood for heat-differential-related breakage.

Early design considerations involving the use of any glass product, especially large IG units, should always include an evaluation of potential thermal stress breakage. Most major glass manufacturers provide online tools that enable specifiers to execute their own thermal stress analyses. However, due to the number of potential variables involved, the glass manufacturer, glazing contractor, glass fabricator, or a qualified building engineer who is familiar with anticipated project conditions should perform such calculations.

Potential conditions that can influence thermally induced stresses and overall probabilities of breakage include:

- outdoor lite selection (i.e. clear, tinted, or coated glass);

- indoor lite selection (i.e. clear, tinted, or coated glass);

- IG unit size (i.e. glass thickness, width, and height); and

- installation conditions.

With respect to installation conditions, factors include:

- building altitude;

- winter temperature range;

- outdoor frame design and color;

- adjacent reflecting surfaces (e.g. woods, blacktop, bodies of water, snow, other buildings);

- outdoor shading patterns (e.g. shading devices, overhangs, site orientation, nearby buildings);

- indoor shading patterns (e.g. blinds, shades, interior walls and partitions); and

- heating register locations.

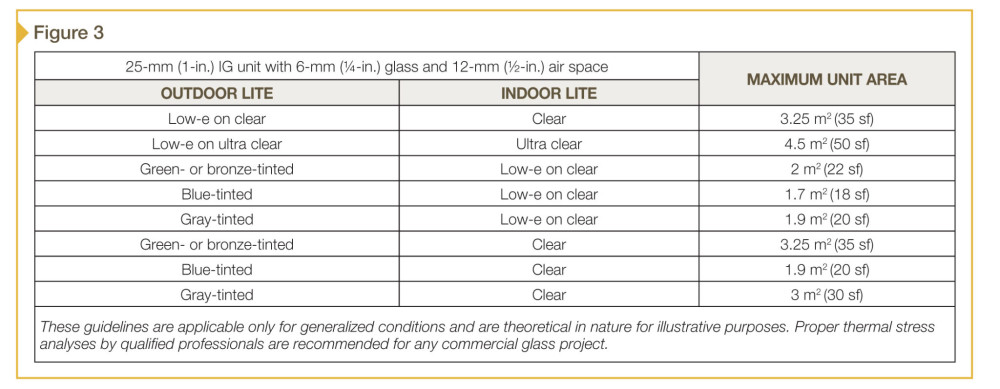

Figure 3 shows the maximum recommended surface area for resisting thermal stress for eight common IG unit configurations incorporating annealed (non-heat-treated) glass that have generalized conditions acting on them. Any IG unit of the same configuration larger than the one specified in this table should be heat-treated. Thorough thermal stress analyses using actual conditions for the related project always are recommended.