Weather-resistant barriers: Advanced technologies for modern construction

By Andrew Irvine

In recent years, moisture management has become increasingly important for multifamily and commercial construction teams due to higher expectations for building performance and more stringent building codes and regulations. Many materials and installation practices contribute to air- and moisture-resistant building envelopes, with weather-resistant barriers (WRBs) playing a pivotal role.

The 2018 International Building Code (IBC) Section 1403.2 defines “water resistive barrier” as “not fewer than one layer of No.15 asphalt felt, complying with ASTM D226 for Type 1 felt or other approved materials, shall be attached to studs or sheathing, with flashing as described in Section 1404.4, in such a manner as to provide continuous water-resistive barrier behind the exterior wall veneer”

The American Architectural Manufacturers Association (AAMA) defines weather-resistant (not “resistive”) barriers as a surface or a wall responsible for preventing air and water infiltration to the building interior. Manufacturers of polymer-based barriers (i.e. building wraps) also distinguish between water-resistive and weather-resistive barriers, with the latter providing the added benefit of also serving as an air barrier for the vertical building enclosure.

The IBC code requirements stipulate minimum requirements for a water- or weather-resistant barrier. Hence, the minimum standard is compared to No #15 felt paper, the original “house wrap” or “building wrap” before all the woven, non-woven, and drainable introductions. When discussing a weather-resistant barrier, look for a “balance of properties,” including bulk air and water holdout, breathability, and durability. All four properties should be present in WRB for optimal functionality and home/structure protection.

The performance of a WRB depends on the material’s ability to maintain its integrity—no matter what comes into contact with it. This article will define the WRB performance characteristics specifiers need to know about and outline key tests and certifications that can help ensure the right material for a project.

Moisture management and drainability

As its most basic function, a WRB must hold out water. A high-performance building wrap will be able to pass both a “water ponding” test, which measures a building wrap’s resistance to a 25.4-mm

(1-in.) pond of water over two hours, and a more stringent hydrostatic pressure test where the material is subjected to a pressurized column of water for five hours.

However, as the trend for tighter building assemblies continues to grow, building wraps must be able to balance permeability with drainability to both prevent water from becoming trapped in the wall and allow any moisture that does become trapped to evaporate effectively.

The drainage efficiency of a building wrap is generally tested in accordance with ASTM E2273, Standard Test Method for Determining the Drainage Efficiency of Exterior Insulation and Finish Systems (EIFS) Clad Wall Assemblies. During the ASTM E2273 test, a spray box with two small openings for water application is sealed to a wall assembly. Next, water is sprayed onto the wall for 75 minutes, with the water collected measured at 15-minute intervals. Water flow and dispersion are held constant throughout the test.

Once the 75 minutes are up, the wall sits idle for an additional hour before measuring the collected water drained from the wall assembly. If greater than 90 per cent of the total applied water has drained and been collected, the wall assembly is said to be in accordance with ASTM E2273. Section R703.9.2 of the 2018 International Residential Code (IRC) and Section 1407.4.1 of the 2018 International Building Code (IBC) require the wall to have an average minimum drainage efficiency of 90 percent when tested in accordance with ASTM E2273.

Given the proliferation of drainable building wraps on the market, builders and specifiers should pay close attention to how quickly bulk water drains, as it can vary significantly. According to ASTM E2273, some high-performance building wraps have been shown to achieve drainage efficiency of greater than 90 percent, and some leverage innovative technologies to take this even higher.

Today’s most advanced building wrap products feature integrated drainage gaps through creping, embossing, weaving, or filament spacers. These new products eliminate the need for furring strips, helping reduce material costs and streamline installation. The cutting-edge drainable building wrap technology is products that create a drainage gap through an additional layer of polypropylene fibers. One of the leading commercial drainable building wraps uses this technology to create a drainage gap and has achieved 96.7 percent drainage efficiency per ASTM E2273 while still handling and installing like a standard building wrap.

This added layer of protection is particularly important in coastal climates and areas subject to heavy wind-driven rainfall. These products can be installed in any direction without affecting performance.

Permeability

A WRB must be able to breathe to prevent moisture vapor from getting trapped in the wall assembly. Permeability measures the amount of vapor transmission that a building wrap will allow over a period of time. ASTM E96 is the Water Vapor Transmission Rate (WVTR), also called Moisture Vapor Transmission Rate (MVTR), which the industry calls “PERMS” or “permeability.” ASTM E96 and ASTM E2273 are industry standards for measuring drainability and permeability. Permeability is the measure of moisture through the WRB or wall system (i.e. it can be tested on a standalone product or as part of a system).

The key to permeability is that when designing a wall, it should have a system of products so there is potential for any water to escape to the outside or exterior of the wall system. If a wall system is designed with no permeability and water gets into the interior, then there would be no mechanism by which the moisture/water could escape to the outside, which could lead to rotting, mildew, etc. Once moisture reaches the exterior, ASTM E2273 or drainage comes into play. Therefore, ASTM E96 and ASTM E2273 are co-mingled in the sense that when designing a wall system, ensure there is a path for moisture to escape to the outside and then once it hits the exterior wall component (here housewrap or buildingwrap or WRB) has a path to escape down the wall system. The key here is keeping water out.

ASTM E96, Standard Test Methods for Water Vapor Transmission of Materials, addresses two testing procedures for measuring permeability—desiccant and water methods.

In the desiccant method, the material to be tested is sealed to a test dish containing a desiccant or drying agent, and the assembly is placed in a controlled atmosphere. Periodic weighing determines the rate at which water vapor has moved through the specimen into the desiccant. In the water method, the dish contains distilled water, and periodic weighing determines the rate of vapor movement through the specimen from the water.

In most wall assemblies, outwardly driven moisture will not cause many problems (unless one is dealing with a material such as stucco painted with a low-perm paint, in which case bubbling and cracking would be visible). However, the inwardly driven moisture presents a problem, especially when conditioned indoor air is much cooler than the warm, moist exterior.

Typically, this inwardly driven moisture vapor is managed by separating the cladding from the rest of the assembly with a capillary break, a gap or a sheathing material able to shed or not absorb or pass water. Impermeable sheathing, such as extruded polystyrene (XPS), is one option for halting inward vapor drive. In these assemblies, the inwardly driven moisture condenses on the surface of the XPS sheathing and drains downward.

However, in situations where a reservoir cladding is paired with a highly permeable sheathing like gypsum board (which can be as high as 50 perms) or a moisture-retentive material such as oriented strand board (OSB), an air gap may not be enough to slow down inward moisture intrusion. In these applications, a WRB is needed to reduce unwanted moisture intrusion.

The International Code Council (ICC) requires a product’s permeance rating to be at least five perms to be classified as a water-resistive barrier instead of a vapor retarder. This distinction stems from the fact that a vapor retarder reduces the rate at which water vapor moves through a material, and the older term “vapor barrier” is still in use, even though “vapor retarder” is more accurate. According to the Department of Energy (DOE), materials are categorized by their ability to resist water vapor diffusion, measured in units called “perms” or permeability. For example, materials with a permeance rating of five perms or higher fall within the range of Class III vapor retarders, which can include items such as house wrap. It is important to note that a higher perm rating does not always indicate a better water-resistive barrier, as the performance of the barrier depends on the specific conditions and requirements of the building.

“Inward Drive – Outward Drying,” a paper written by building scientist Joseph Lstiburek,1 recommends that specifiers aim for the “sweet spot” of 10–20 perms to achieve the desired moisture protection and breathability balance. Achieving the optimal perm rating ensures that while water is prevented from entering the wall cavity, ideal levels of moisture vapor are still allowed to escape. He writes that if it is too high, the moisture driven out of the back side of a reservoir cladding, such as brick or stucco, into the air space will blow through the layer and the permeable sheathing into the wall cavity. Too low, and the outward drying potential of the cavity is compromised. Fortunately, building wrap technology, mainly using a “systems” approach, can help builders hit the sweet spot for permeance.

Air holdout

The Air Barrier Association of America (ABAA) defines an air barrier as a system of assemblies within the building enclosure designed, installed, and integrated to stop the uncontrolled air flow into and out of the enclosure. Establishing a continuous air barrier is crucial for several reasons, as it isolates the indoor environment and significantly impacts the overall energy efficiency, comfort, and indoor air quality (IAQ) of a building. According to DOE, up to 40 percent of the energy used to heat and cool a building is consumed due to uncontrolled air leakage. A continuous air barrier also helps lower greenhouse gas (GHG) emissions by reducing heating and cooling costs.

An air barrier controls the airflow between conditioned and unconditioned spaces, serving as the primary boundary between indoor and outdoor air. In multi-family construction, it also separates the conditioned air of individual units and their adjacent units. However, it is important to note that while many materials can meet the ASTM air leakage requirement, the real-world performance of an air barrier system depends on proper installation. The material’s durability on the jobsite and the integrity of connections are critical; even one unsealed seam or tear can compromise the entire system’s effectiveness. It is also essential to distinguish between air and water-resistive barriers, as they serve different functions in building design.2

For an individual building material to be classified as an air barrier, its air permeance must be equal to or less than 0.02 L/(s•m2) at 75 Pa (0.00394 cfm/sf at 1.57 psf) when tested following ASTM E2178, Standard Test Method for Air Permeance of Building Materials. However, this air permeance test only measures the amount of air migrating through the material itself, not through holes or gaps in the larger assembly. Therefore, it is important to consider a material’s effectiveness as an air barrier largely depends on proper installation and the use of compatible tapes, fasteners, and sealants.2

Understanding how an air barrier material performs when installed as part of a compatible system is much more valuable. To receive approval from ABAA, an air barrier must pass the organization’s air leakage standards when tested in accordance with ASTM E2357, Standard Test Method for Determining Air Leakage of Air Barrier Assemblies. This type of test is intended to more accurately replicate how a wall system will perform in a real-world setting. It includes various elements, such as wind loading, making it a more reliable measure of the system’s performance. When tested in accordance with this standard, the air barrier must be 0.20 L/(s•m2) @ 75 Pa (0.04 cfm/sf @ 1.57 psf) in both directions (i.e. infiltration and exfiltration).

Air barriers can also be defined through whole-building testing in accordance with ASTM E779, Standard Test Method for Determining Air Leakage Rate by Fan Pressurization. This test method is intended to measure the airtightness of building envelopes of single-zone buildings. For this test method, many multi-zone buildings can be treated as single-zone structures by opening interior doors or inducing equal pressures in adjacent zones.

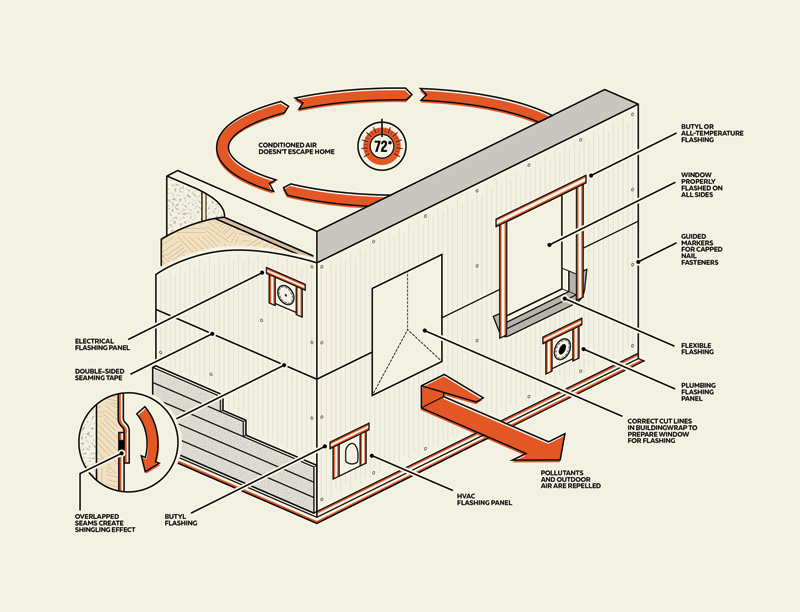

Taking a system approach

The key word in this discussion is assembly or system, as both are appropriate in this context. While the term “assembly” may evoke thoughts of fire-rated wall constructions, it is also important to note that those are simply collections of components tested together as a unit. In the case of air and moisture management, the WRB must be considered alongside related elements such as flashing tapes, sealants, and other accessories. These components form an integrated wall assembly or system designed for bulk air and water holdout.

For example, sealants with high solvent or plasticizer content can damage bitumen flashing products, causing functional and aesthetic issues. When seams and tears are not adequately taped, windblown rain can infiltrate the assembly. Failure to use galvanized roofing nails or plastic cap nails to attach the WRB to the sheathing and framing can also compromise performance.

To counter this problem, some manufacturers have developed a system approach that includes compatible tapes for seaming and adhesive flashings for openings. When installed together, these systems are often assured through extended warranties from the manufacturer. When in doubt, always check the manufacturer’s website for additional guidance.

Durability

Construction sites can be challenging, and if the building wrap is not tested to withstand tears, scratches, prolonged exposure to UV light, and common construction chemicals, it will not perform how it needs to once installed.

Regarding building wrap, the ICC tests durability on two primary indicators: tensile strength and tear resistance. These factors are critical because the wrap needs to withstand the handling and installation process without compromising its air- and water-resistive properties.

Tear resistance, as measured by trapezoidal tear tests (ASTM D1117/ASTM D5733), is a good measure for predicting a building wrap’s ability to withstand the rigours of the job site and to stay on the wall after installation. “In-plane” is the best measurement of tear resistance. The trapezoid tear test, the best measurement of in-plane tear resistance, takes place when the building wrap is fastened to the wall and is subjected to tearing in the plane of the wall.

Some building wraps claim tensile strength based on ASTM D882, a test for thin plastic sheeting, not nonwoven fabrics. Since the product is never used this way, these measurements are not meaningful. However, the grab tensile measurement is meaningful. ASTM D5034, Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test), tests a 1.2 x 1.8 m (4 x 6 ft) material sample and clearly states it is designed for nonwoven fabrics, making it a much better metric for evaluating building wraps.

Another factor to consider is the ability of a building wrap to withstand incidental scratches from utility knives, nails, and other tools. While no ASTM standards govern scratch resistance testing for building wraps, some manufacturers commission third-party testing to demonstrate the performance of their products. A scratch-resistant wrap is less likely to suffer from surface damage that could weaken the material, ensuring it lasts longer and continues to perform effectively. Ensure that the wrap being used has been tested for scratch resistance.

UV resistance

Another primary performance attribute in a high-performance WRB is its ability to stand up to UV exposure. This is a critical point of differentiation between weather barriers, as prolonged exposure to UV radiation can cause material degradation, leading to loss of tensile strength, delamination of surface layers, and reduced water repellency. This is especially true in commercial construction, where there are already prolonged construction schedules that are often slowed by several factors. For these reasons, UV exposure must be at the forefront of mind when selecting a system of weather protection products.

While the goal should be to clad the exterior of the building as quickly as possible, projects are often delayed, leaving WRBs vulnerable to longer-than-expected exposure to the sun. Many building wraps currently on the market only offer up to 120 days of UV resistance, with the best offering up to 12 months without degradation to their performance capabilities. This can be an incredibly important differentiator for commercial projects where extended project timelines often leave the WRB exposed for a considerable amount of time.

Surfactant resistance

When evaluating WRBs, specifiers should seek an optimal balance of performance characteristics, including air and water resistance, durability, and sufficient permeability. However, one property, surfactant resistance, is commonly overlooked by building professionals. Builders and contractors who do not have a basic understanding of surfactants and how they impact the performance of a building wrap could potentially jeopardize the long-term durability of the exterior wall assembly.

Surfactants (surface active agents) are contaminants that lower the surface tension of a liquid, allowing it to penetrate deeper into the WRB material. Water soluble extractives in wood, such as tannins and wood sugars in redwood and cedar, are examples of surfactants that contaminate the surface of building wraps. In addition, surfactants can be found in detergents, soaps, and other cleaning solutions used to power wash siding, making surfactants almost impossible to avoid.

Why is this a problem? Surfactants promote the loss of water repellency, causing “wetting” of the building wrap surface. Once this occurs, water can more easily pass through the microscopic openings in the building wrap. Once moisture finds its way into the building envelope, it can threaten its structural integrity, causing exterior surfaces to deteriorate. Bulk moisture intrusion can also support mold and rot, which cause structural damage and pose serious health hazards to building occupants.

When choosing a building wrap, pay attention to its surfactant resistance capabilities. Not all wraps will provide the same surfactant protection, if any at all. Recent testing conducted by an accredited third-party testing facility with ISO 17025, Miami-Dade, American Architectural Manufacturers Association (AAMA), and AABA certifications compared three well-known weather-resistant barriers when subjected to a common surfactant (dish soap and water) and revealed that one outperformed the other two across the board.3

Although it is never advisable to expose WRBs to surfactants, most will be exposed despite best intentions. So, builders and contractors must select a wrap resistant to these chemicals. Due to the vast amount of building wraps and moisture management products on the market, it is more imperative than ever to make the right product selections to design and build wall systems that perform to today’s high performance, durability, and moisture control standards.

Conclusion

Specifying the right WRB is critical for achieving a high-performance building envelope that meets today’s stringent building codes. Understanding the key performance measures—such as moisture management, permeability, air holdout, durability, UV resistance, and surfactant resistance—ensures a building wrap that protects against the elements and enhances the overall longevity and energy efficiency of the structure. Taking a systems approach and specifying WRB materials that strike an optimal balance between these various performance characteristics ensures informed decisions that contribute to the success and sustainability of projects.

Notes

1 Refer.

2 Learn about the different types of barriers and their functions.

Author

Andrew Irvine is a senior product manager at TYPAR Construction Products. He has extensive experience in the building and construction industry, including global product management, national account management, and finance. Irvine is responsible for the building and construction portfolio, including the TYPAR product line.

Key Takeaways

Moisture management is crucial in construction, especially for multifamily and commercial buildings. Weather-resistant barriers (WRBs) are key for preventing water intrusion and promoting air and moisture control. WRBs must balance permeability, drainability, and durability. Performance tests such as ASTM E2273 ensure efficient drainage and moisture management. WRBs should also resist UV degradation, air leakage, and surfactants to maintain performance. Specifying WRBs that work within a system and meet building codes ensures long-lasting, energy-efficient buildings. Proper installation and material compatibility are essential for optimal performance in controlling moisture and airflow.