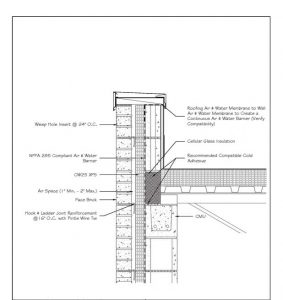

Cellular glass insulation

Cellular glass insulation has a unique chemistry, and a special manufacturing process is used to produce it (Figure 1). Sand is the primary ingredient used in the manufacturing of cellular glass, along with limestone, soda ash, etc. The ingredients are melted into a molten glass, which is then cooled. The cooled glass, called cullet, is mixed with carbon black and crushed into a fine powder. The powdered mixture is then heated in an oven to cause a chemical reaction. This results in a glass matrix of insulating ‘bubbles’ similar to how baking soda makes a cake to rise. The finished product comprises of millions of completely sealed glass cells offering a number of performance benefits. ASTM C552, Standard Specification for Cellular Glass Thermal Insulation, defines the basic physical property requirements of cellular glass insulation. Performance benefits associated with cellular glass as an insulating material are noted below.

Impervious to moisture

The 100 percent glass nature of cellular glass makes it impervious to moisture and therefore makes it a suitable material to protect against water infiltration in liquid or vapor form. As a high performance material, cellular glass is always used in conjunction with a high-quality membrane. Therefore, even if a large enough point of impact crushes a layer of brittle foam glass, the membrane provides an additional layer of protection.

Noncombustible

As a glass, it neither contains fuel content, nor burns, spreads fire, or presents a fire risk in the structure.

Dimensional stability

Cellular glass insulation consists of pure glass with a low coefficient of thermal movement, comparable to concrete and steel. This level of stability means there is no warping, dishing, or shrinking of the insulation, even as the temperature fluctuates over seasons. Used in commercial building roofs, cellular glass provides a stable foundation for the roofing membrane, minimizing the stress arising from the constant flexing that causes a material to deteriorate over time. From a flexibility and ease of installation viewpoint, cellular glass can also be tapered to address various drainage objectives and is incredibly easy to cut.

Redundancy

From an installation perspective, cellular glass is typically seated in an asphalt base and joints are also sealed with the same. Unlike foam plastic, cellular glass is entirely resistant to heat and tolerates solvents and bitumen. Cellular glass can also be sealed to functionally serve as a secondary waterproofing membrane. The key benefit for mission critical buildings is, as a roofing membrane degrades over time, the cellular glass provides a secondary layer to stop water infiltration.

Compressive strength

The lowest compressive strength for cellular glass is in the range of 345 to 483 kPa (50 to 70 psi), and can be much higher without deflection under load. Contrastingly, the compressive strength of foam plastics typically tops out in the 345 to 483 kPa range. The compressive strength range allows cellular glass to support high loads without deflection or movement, even under sustained stress. Applications well-suited for cellular glass insulation include rooftop plazas that support heavy equipment, traffic, and parking.

Resistance to acid and chemicals

Naturally inert, cellular glass is unaffected by chemically aggressive agents or environments where these exist. The pure glass composition does not react with organic solvents and acids.

Ecologically responsible

Cellular glass delivers ecological benefits as it is manufactured using more than 60 percent recycled glass. Completely inorganic, cellular glass does not contain ozone-depleting propellants, flame retardants, or binders, and is free of volatile organic compounds (VOCs).

Resistant to infestation

As an inert insulating material, cellular glass does not support the growth of microorganisms or bacteria and cannot rot. It is resistant to pests such as insects and vermin.

Cellular glass for roof replacements

In addition to new construction, cellular glass is a long-lasting solution for roof replacements. The James W. Jardine Water Filtration Plant adjacent to the Navy Pier in Chicago, Illinois, provides an example of cellular glass used in a re-roofing project. In 2014, the 50-year-old graveled coal tar pitch roof was demolished and replaced with 712,000 board feet of cellular glass insulation that protected the thermoplastic membrane. Of significant note is that the demolition was not the result of the failure of cellular glass, but rather the deck support structure had deteriorated from years of exposure to treatment tanks within the building and the roof had to be removed to replace the structure. The resulting roof stands up to the Windy City’s weather extremes, as well as chemical agents, sunlight, and the acidic deposits of flocks of birds congregating on the rooftop. The Eugene Sawyer Water Purification Plant, also in Chicago, will be going through the same reconstruction beginning later this year.