Photos courtesy Chris Bennett

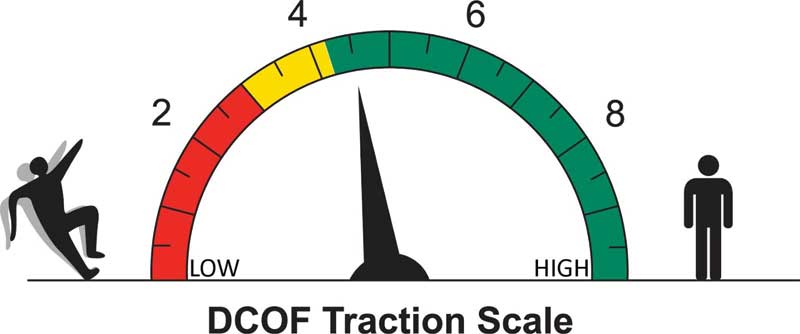

“Due to the increased popularity of polished/exposed concrete surfaces as its own floor finish, more people, including owners and facility directors, are much more conscientious about coefficient of friction requirements,” says Eric Lussier, CSI, CDT, co-founder of the Let’s Fix Construction education series. (Visit www.letsfixconstruction.com for more information on the series.) “From my experience, architects are seeking direction from industry professionals who can point them to proper standards and usage to meet these needs.” There are other standards from manufacturer organizations competitive to the concrete floor industry (e.g. Tile Council of North America’s [TCNA’s] ANSI A137.1, Tile Slip Test) that do not fall within the safety benchmarks of NFSI B101.3. However, many manufacturer trade associations from various flooring industries have promoted ANSI A137.1 and its derivatives as their preferred standard.

Russell Kendsior of NFSI notes, “The TCNA standard excludes polished concrete in its scope and only applies to un-installed ceramic tile. ANSI/NFSI B101.3 specifically states the standard applies to polished concrete.” NFSI is also the designated ANSI standard-developer for slip, trip, and fall prevention.

Image courtesy National Floor Safety Institute

Conclusion

In the pursuit of beauty and COF performance, specifiers can take simple steps to ensure safe exposed concrete floor finishes. Indicating ANSI/NFSI B101.3 or ASTM E303-93 as the COF reference standard in concrete floor finish specifications sets the bar for how the client’s floor will be measured to ensure consistent COF even when the floor is wet or contaminated. Requiring quality assurance guidelines in your specifications will help ensure the final performance qualities of your exposed concrete floor.

Tony Heimkes, Hines-Property manager at Galleria Shopping Center (Edina, Minnesota), states, “Our commitment to safety is first priority for our guests, merchants, and visitors. Flooring concepts achieving NFSI B101.3 benchmarks give us the reassurance this commitment will be upheld.”

Chris Bennett, iSCS, CDT, is a critical voice in the development of sustainable concrete solutions to replace expensive, outdated methods. His firm, Bennett Build, leads project teams in lowering the economic and environmental costs of designing and implementing stronger concrete systems. He can be reached at www.BennettBuild.us.

Great to hear this. I may appreciate the author for this.