Fully tempered glass and spontaneous fracture

Photo courtesy Simpson Gumpertz & Heger (SGH)

This article was originally published in July 2018 by John A. Jackson and Thomas A. Schwartz. It has been refreshed and updated to further expand on the subject, including updates in industry standards and codes regarding the use of fully tempered glass in buildings, as well as the authors’ ongoing experience and recommendations since its original publication. The article now also features a new third author, Christopher J. Brandmeier.

It is a beautiful spring morning. Imagine sitting at a desk along the outside wall of an office, when all of a sudden, without warning, you hear a sudden pop. On looking up, you notice the glass in the wall next to you has shattered into thousands of small fragments.

So, what happened? What caused the glass to break on its own? You likely witnessed a phenomenon known as spontaneous fracture of fully tempered glass, and unfortunately, you are not alone.

Glass has a long and evolving history as a building material. In architectural facades, it not only expresses the aesthetic aspirations of a project, but also creates a compelling relationship of simultaneously separating and connecting the interior and exterior environments. In contemporary construction, architectural glass applications push the boundaries of the material’s performance: acting as a structural element, providing thermal and acoustic separation, and regulating daylight and solar heat gain.

To meet these demands, contemporary glass is highly customized through a series of manufacturing and fabrication processes to suit the specific architectural and technical requirements of a project. These include float glass production, where molten raw materials are transformed into flat glass sheets, and heat treatment, where glass is strengthened to meet safety and structural requirements. Additional processes such as application of low-emissivity (low-e) coating, ceramic frit, bird-friendly coatings, lamination, and assembly into insulating or vacuum insulating glass units (IGUs) further tailor the glass project needs.

However, it is within float glass production and tempering ovens that the conditions for a potential serious issue, spontaneous fracture caused by nickel sulfide (NiS) inclusions, can arise. These small, seemingly benign NiS inclusions introduced during the float process, combined with the rapid cooling/induced internal stress during glass tempering, and the subsequent exposure of the glass to heat in-service, create the potential for delayed, unpredictable breakage of fully tempered glass. Despite the industry’s recognition of this problem since the early 1960s and manufacturers’ efforts to limit it, spontaneous fracture of fully tempered glass continues to be an issue in architectural glazing to this day.

In this article, the authors will explore the different architectural glass types and strengthening methods, glass breakage behavior, why NiS inclusions form, and how they lead to spontaneous fracture of fully tempered glass. They will also review current industry practices and provide recommendations for risk mitigation.

Glass types and strengthening methods

Glass types

Soda-lime silica glass is the most common type employed in architectural applications. It is produced from raw materials including silica sand, sodium carbonate (Na2CO3), lime, various metal oxides, and cullet (recycled glass). These ingredients are melted in a furnace at temperatures exceeding 1500 C (2700 F). The molten glass is then floated on a bath of molten tin, a process that gives rise to the term “float glass,” and slowly cooled in a controlled manner, or annealed, to minimize internal stresses.

All float glass begins as annealed glass, but subsequent heat treatment (discussed further in the next section) can be applied to annealed glass to produce either heat strengthened or fully tempered glass:

- Annealed glass (not heat treated, weakest strength)

- Heat-strengthened glass (heat treated, moderate strength)

- Fully tempered glass (heat treated, highest strength)

Beyond strength, fully tempered glass offers a safety advantage over annealed and heat strengthened glass: when broken, it shatters into smaller, safer fragments compared to the alternatives and, therefore, is suited for meeting code requirements for safety glazing. However, these benefits come with trade-offs. Heat treated glass can exhibit increased optical distortion (e.g. bow/warp, roll wave, anisotropy) compared to annealed, and more critically, fully tempered glass suffers from an often-overlooked risk of spontaneous fracture during service.

Heat treatment

Glass, by nature, is strong under compressive forces but relatively weak under tensile forces. Heat treatment is used to strengthen annealed glass by introducing compression at the exposed surface of the glass, which offsets tensile stresses that can lead to breakage. This strengthening occurs during a carefully controlled heating and cooling process.

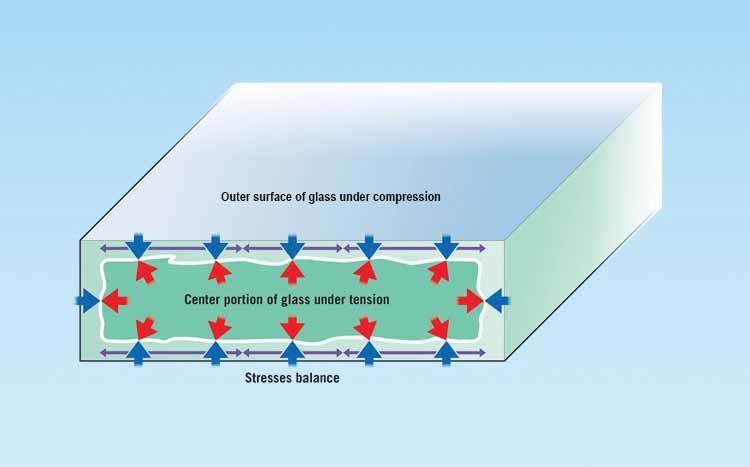

Illustration courtesy Vitro Architectural Glass

In heat treatment, which occurs after glass is cut to size and its edges are finished, annealed glass is reheated to approximately 650 C (1200 F) in a tempering oven, then rapidly cooled with high-velocity air jets in a process known as quenching. The rapid cooling locks the outer surfaces of the glass in place while the core remains hot and pliable. As the core gradually cools and contracts, it places the outer surfaces into permanent compressive stress, known as residual compressive surface stress (RCSS). To balance the forces from the compressed outer surface, the interior of the glass holds equal and opposite tensile stress (Figure 1). The glass after heat treatment can be thought of like post-tensioned concrete where the concrete is in compression and the post-tensioning strands inside are in tension.

The faster the cooling, the greater the level of RCSS. According to ASTM C1048, Standard Specification for Heat-Strengthened and Fully Tempered Flat Glass, the minimum residual compressive surface stress for heat treated glass is:

- 24,132 to 51,711 kPa (3,500 to 7,500 psi) for heat-strengthened glass

- 68,948 kPa (10,000 psi) for fully tempered glass

This outer compressive layer protects the heat treated glass against surface flaws (which can lead to stress concentrations as discussed in the next section) and applied tensile stresses (e.g. due to bending from wind loads), significantly enhancing its overall strength and durability.

Glass design strength and breakage behavior

Glass strength

Glass is a brittle material, meaning, unlike other ductile materials such as metals, glass fracture is often sudden—without yielding, significant deformation, or warning. As is typical with brittle materials, the effective strength of glass is governed by the presence of surface flaws, which act as stress concentrators. These flaws form naturally during manufacturing, from handling and installation, and from in-service weathering of the glass, and their effects are addressed in engineering design standards. Since maximum bending stresses occur at the glass surface, where flaws are most likely to occur, the introduction of surface compressive stress through heat treatment effectively counteracts these potential stress concentrations on the glass surface and significantly improves its load resistance.

Stress-concentrating flaws occur randomly and can vary significantly from one glass lite to another, so glass strength is defined statistically, using statistical probability of breakage (SPB). This results from the statistical probability surface flaws will be present, and the ability of these flaws to concentrate applied stresses, leading to fracture under load. The common industry design standard for SPB of architectural glass upon first application of the design load (e.g. wind load) is eight lites per 1000 (8/1000). A designer may select a lower SPB, say 1/1000, for applications such as overhead glazing (e.g. glass sloped 15 degrees or more from vertical) and other critical “structural” applications (e.g. drilled, point-supported, or clamped glass). ASTM E1300 and other glass engineering design standards provide methods for design of architectural and structural glass, which accounts for the SPB and glass heat treatment.