Fully tempered glass and spontaneous fracture

Glass fracture

Photo courtesy Simpson Gumpertz & Heger

Glass fracture can occur due to a variety of reasons, such as impact (accidental or otherwise), pre-existing glass damage (e.g. at edges) which may compromise the ability of the glass to resist design loads, glass binding or glass-to-metal contact within the frame, damage from construction activities such as weld splatter, or overstress from applied loads (e.g. wind, thermal) to due improper design, fabrication, and/or installation. Spontaneous fracture is a term for the sudden breakage of glass without any apparent external stress; most commonly due to inclusions within the glass of which the most common is nickel sulfide (NiS).

When fully tempered glass breaks, the residual tension built into the glass core drives cracks throughout the plate explosively, producing a diced fracture pattern. If the fragments do not immediately leave the opening upon breakage, one can see a series of primary cracks radiating from the point of origin, in what is commonly called a “starburst” pattern (Figure 2).

Nickel sulfide (NiS) formation, spontaneous fracture mechanism, and identification

NiS formation in architectural glass

Impurities can be introduced into glass during the melting of the raw ingredients in the furnace at the float plant. Many impurities are benign, but nickel sulfide (NiS) can be problematic.

The sulfur in NiS commonly derives from sodium sulfate (Na2SO4), employed as a fining agent in the molten glass mixture typically used to reduce the presence of air bubbles. There is debate within the industry as to exactly how nickel is introduced into the mix, but several known causes include:

- contamination of raw materials

- abrasion of the storage/handling equipment of raw materials releasing nickel-bearing metals such as stainless steel

- the inside surfaces of the furnace itself

Most float glass manufacturers are aware of the risks of contamination and include details within their quality assurance/control (QA/QC) procedures for minimizing contamination.

NiS is an unusual compound because it has different high and low-temperature crystalline structures, namely the alpha phase (i.e. high temperature, greater density, smaller volume, and less stable crystalline structure) and beta phase (i.e. low temperature, less dense, larger volume, and more stable crystalline structure). The cumulative effect of heat causes NiS particles to transition from the alpha to the beta phase. During the rapid cooling process of tempering, the NiS particle may be locked into its smaller, but less-stable alpha phase. (The slow cooling process for annealed glass can allow the NiS particle to transform from the alpha phase to the more-stable beta while the material is still soft and has the ability to accommodate the inevitable expansion without adverse consequences.)

The mechanism of NiS-induced spontaneous fracture

If the NiS particle is locked in its alpha phase during the tempering process, it can eventually transition to the more stable beta phase under the long-term accumulation of in-service heat from external sources such as the sun or heating systems of the building. When this occurs in a particle located within the mid-plane of the glass, its expansion, in conjunction with the residual tensile stress surrounding it, can propagate a micro crack or “vent” in the glass. When the vent reaches a critical length, the residual tensile stress in the glass core causes the crack to propagate throughout the lite and fracture spontaneously.

NiS-induced fractures show these characteristics:

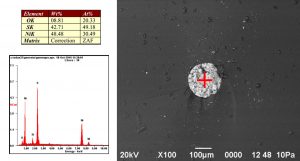

- Two distinctive glass fragments at the fracture origin have a unique shape (roughly hexagonal or pentagonal) and are generally larger than the other fragments. This is often referred to as the “cat-eye,” “butterfly,” or “figure eight” pattern (Figure 3).

- The NiS inclusion is visible at the mid-plane of the fractured interface between the two cat-eye fragments (Figure 3). The inclusion, or “stone,” is spherical and approximately 0.1 to 0.2 mm (4 to 8 mils) in diameter.

- No apparent sign of localized crushing of the glass surface at the fracture origin (surface crushing indicates potential impact).

As discussed previously, all float glass (including annealed, heat-strengthened, and fully tempered) may contain NiS impurities. However, NiS-induced fracture occurs only in fully tempered glass. The authors are not aware of any incidents of spontaneous fracture attributed to NiS in annealed or heat-strengthened glass, as long as the heat-strengthened glass has its RCSS within the limits (i.e. 24,132 to 51,711 kPa) set forth in ASTM C1048. One of the reasons for limiting the RCSS of heat-strengthened glass to this range is to provide a moderate level of strength increase over annealed glass, but limit the RCSS safely below the minimum RCSS of 68,948 kPa of fully tempered glass at which NiS-induced fracture is known to occur. The authors have found NiS-induced fractures in glass with RCSS at 56,537 kPa (8200 psi) or above. This level of RCSS provides sufficient residual tensile stress around a NiS particle, located mid-plane, to propagate fracture if and when the impurity undergoes its phase transformation.

Non-destructive detection of NiS

In-place, non-destructive test methods for identification of NiS inclusions in fully tempered glass, which could eventually lead to spontaneous fracture, are generally impractical in large-scale manufacturing processes or in-service applications. Several methods have been tried for locating NiS inclusions on in-service glass (e.g. ultrasound, laser imaging, photographic, and light detection), in the hope of identifying potential inclusions before they break the glass. These methods are labor intensive, time consuming, expensive, require specialized equipment, and highly prone to user error. Even if an inclusion is found near the mid-plane of the glass, the crystalline state of the NiS is still unknown. So, one does not know if the phase transformation has already taken place and whether the inclusion is benign or not.

Post-fracture testing and verification of NiS

The classic signs of a NiS-induced break (e.g. the distinctive “cat-eye” fragments at the fracture origin and no apparent localized crushing of the outer surface of the glass that might indicate an impact) are often insufficient to positively identify a break for a warranty claim. To determine conclusively the cause of breakage was NiS inclusion, the cat-eye glass fragments should be tested in a laboratory (Figure 4).

If NiS-induced spontaneous fracture is suspected, it is crucial to identify the fracture origin and preserve it for further forensic testing. This is true even if testing is not readily available or the breakage has not yet become a regular occurrence. Too often in the authors’ experience, spontaneous breakage occurs on a building before the owner becomes aware of a pattern of breakage, and the glass origin fragments that would have positively verified NiS-induced fracture and the extents of the issue as well as triggering warranty claims are no longer available.

Whenever spontaneous glass breakage is suspected, it is first critical to make safe the area around the broken glass to minimize risks potential injury (e.g. notification of building staff, cordoning off the area nearby and below the glass). Preservation of a fracture origin, typically includes documenting the break in-situ with photographs, carefully applying a clear tape or film to at least a 152 x 152 mm (6 x 6 in.) area around the origin (i.e. the center of the starburst pattern), and finally carefully removing the fragments as a contiguous sheet, making sure to retain the “cat eye.” Other glass from the broken panel can be safely discarded, typically by an experienced glazing contractor.